Flyers

d² Substructure System

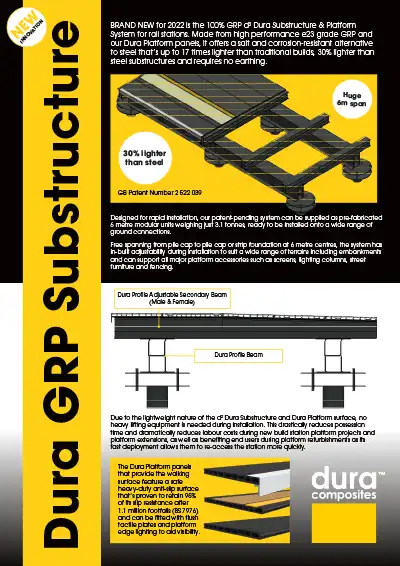

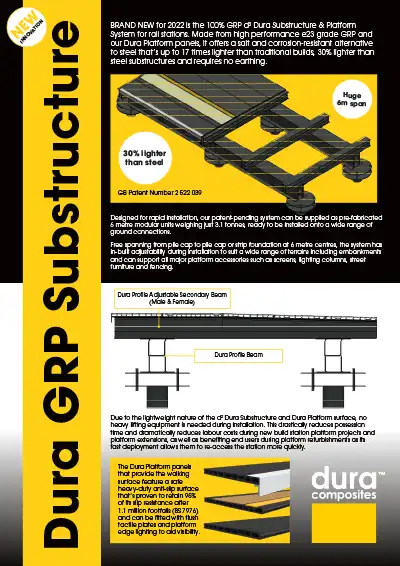

100% GRP d² Dura Substructure & Platform System for rail stations. Made from high performance…

DownloadRail | +44 (0) 1255 440291

General | +44 (0) 1255 446838

Sales Support | +44 (0) 1255 423601 (Option 5)

Transport | +44 (0) 1255 462567

We welcome the opportunity to discuss your environmental sustainability objectives early in the procurement process and are happy to detail the significant embedded carbon savings that can be made by choosing our d² station platform and related products over other materials on the market.

With almost a billion passenger rail journeys made in the UK each year, the stations where people start and end their journeys are a key focus for improvements to the passenger experience. Changes to rolling stock require longer platforms, whilst Victorian platform canopy installations and pedestrian footbridges require replacement or refurbishment as they reach the end of their service life.

With a best-in-class reputation for delivering on even the most challenging rail projects, we design, manufacture and supply sustainable low-maintenance composite product solutions that play their part in helping run a safe and efficient railway for passengers.

Our modular GRP Dura Platform allows contractors to replace or overlay onto damaged or subsided platforms a low maintenance, modular, lightweight, height adjustable structure that enhances safety and can reduce any PTI gaps to comply with current standards, improving the passenger experience.

Dura Platform complies with Network Rail specifications, boasting unparalleled efficiency in platform installation and a remarkable reduction of up to 65% in installation time. Our most popular variant is Dura Platform 40, which serves as the foundation for two installation methods, depending on your project needs. Our GRP/Steel Hybrid Platform solution is primarily for new platforms and extensions, while our collaboration with Hammond ecs Ltd utilises the Mountbridge™ system, which achieves overlays and re-gauging with ease.

Beyond the platform, our other composite station solutions minimise the requirement for maintenance over or across live infrastructure.

Our lightweight, durable composite dagger boards achieve a EN13501 Class B – s1 d0 fire rating that’s ideal for canopy projects as a fit-and-forget solution. We also design and supply award-winning footbridge treads and landings, end-of-platform gates, steps and fencing – all made from our advanced d² product range with its low embodied carbon and full recyclability.

Dura Platform can cut platform installation time by up to 65% – benefitting passengers who are able to re-access the station sooner and saving labour costs for rail contractors.

Efficient in locations where traditional build systems are not suitable due to limited access, restricted possession times and/or passenger disruption concerns.

Versatile platform systems that allow for easy height and pitch adjustment, incorporating a 1 in 40 fall to aid water runoff.

We employ two railway platform installation methods, both utilising our advanced platform surface, Dura Platform 40. Whatever your platform requirements, our solutions cover any scenario.

Find out how our market-leading composite products and applications are reshaping the industry.

Flyers

100% GRP d² Dura Substructure & Platform System for rail stations. Made from high performance…

Download

Datasheets

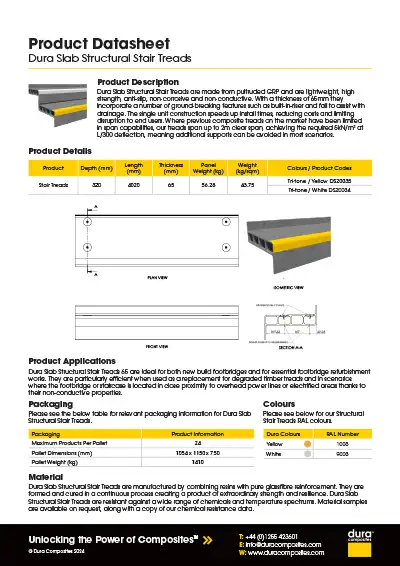

Dura Slab Structural Stair Treads are made from pultruded GRP and are lightweight, high strength,…

Download

Installation Manuals

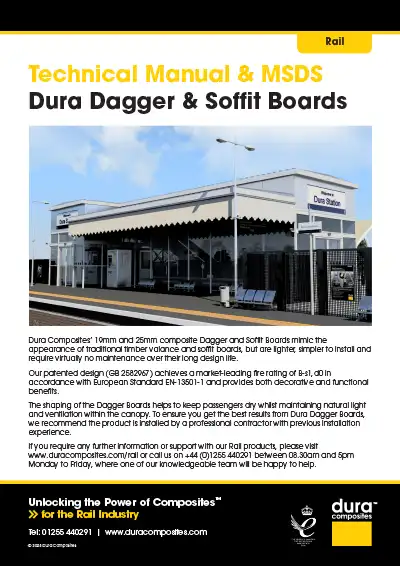

Our 19mm and 25mm composite Dagger and Soffit Boards mimic the appearance of traditional timber…

Download

Installation Manuals

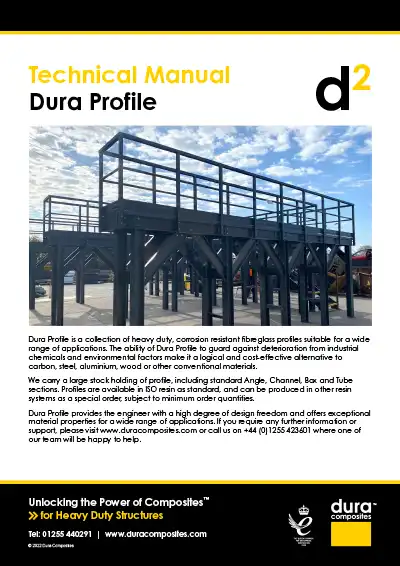

This Dura Profile Install Manual enables designers and contractors to gather the necessary material data,…

Download

Brochures

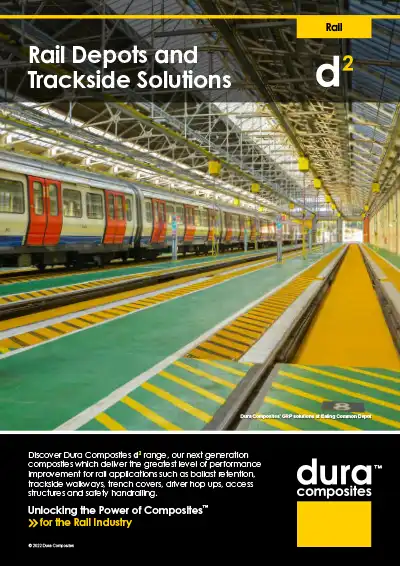

Discover Dura Composites d² range, our next generation composites which deliver the greatest level of…

Download

Brochures

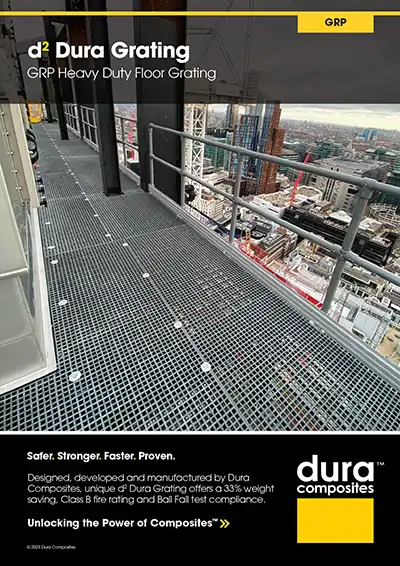

Designed, developed and manufactured by Dura Composites, unique d² Dura Grating offers a 33% weight…

Download

Brochures

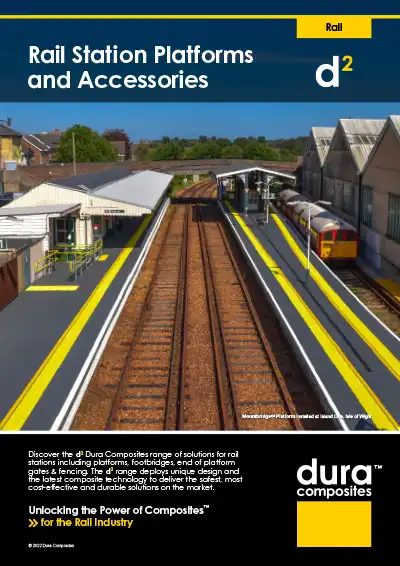

Discover the d² Dura Composites range of solutions for rail stations including platforms, footbridges, end…

DownloadWe’re helping to answer the major challenges facing Britain’s railway network such as capacity, reliability and efficiency. Talk to our experienced team about how you can tap into our specialist knowledge and engineering capability for your project.