Brochures

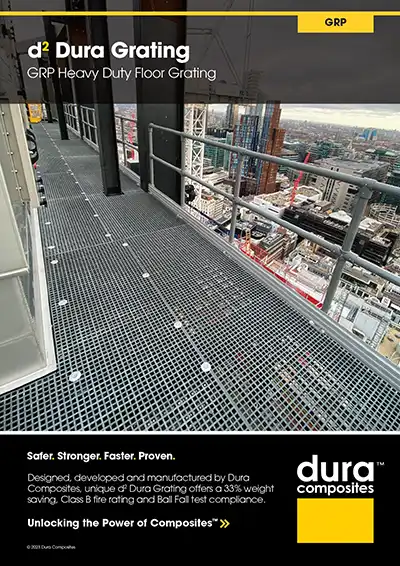

d² Dura Grating

Designed, developed and manufactured by Dura Composites, unique d² Dura Grating offers a 33% weight…

Download

General Sales | +44 (0) 1255 446838

Sales Support | +44 (0) 1255 423601 (Option 5)

Transport | +44 (0) 1255 462567

Rail | +44 (0) 1255 440291

Industral & Commercial | +44 (0) 1255 440290

High-Rise | +44 (0) 1255 446830

Decking & Cladding | +44 (0) 1255 440298

Marine | +44 (0) 1255 440297

d² Dura Grating is a patented GRP grating series with incredible structural performance but less embodied carbon. Designed, developed and available exclusively from Dura Composites, our fibreglass grating range is manufactured for maximum performance, achieving an industry-leading Class B fire rating in accordance with BS EN 13501-1.

Our market-leading GRP flooring designs offer low slip potential in both dry and wet weather conditions, while their state-of-the-art composition ensures maximum safety tested to over one million footfalls. We have developed a whole range of FRP/GRP Grating products to suit a number of application requirements – each ranging in mesh size, resistance and price, all offering outstanding safety, performance and durability but with up to 33% less embodied carbon to boost the sustainability of your walkway project.

Regardless of your needs, you’re guaranteed durable, hard-wearing GRP flooring that adheres to all health and safety requirements. What’s more, our grating products are lightweight and easy to handle, making installation faster and more cost-effective. They also require little to no maintenance over the course of their life-cycle, ensuring a non-corrosive, slip-resistant surface for years to come.

3D Model: d² Dura Grating Standard Mesh

Dura Grating is part of our d² range of enhanced performance products.

d² Dura Grating is highly engineered fire-rated, non-conductive, non-corrosive flooring. Small mesh holes throughout the range meet 20mm and 35mm Ball Fall tests. Gritted anti-slip surfaces maintain 95% performance even after one million footfalls, showcasing exceptional durability.

Because we’re up to 33% lighter than alternative GRP grating with no loss of performance, you can use lighter or smaller products to reduce your project scale. You can design and specify with confidence, ensuring the strongest and most cost-efficient product combination for your specific load and deflection needs.

Our patented GRP grating designs use less raw material without compromising strength or performance, resulting in carbon savings of up to 33% versus competitor products. We’re also the only company able to provide the option to repurpose your product at the end of its use, making us the greenest choice.

We freely share our material science insights online so you can make factual comparisons of d² products versus steel, wood or other GRP and conveniently see how our products perform – based on fact not guesswork. We also have a measurable impact on sustainability as d² has already saved almost 5 million kilograms of CO2.

d² GRP Grating can be applied in all industries where GRP mesh grating is used today and encapsulates a high strength to weight ratio, safe anti-slip surface and a unique patented and design-registered design.

The versatility of our GRP grating, its low embodied carbon and long design life, makes it a preferred choice for diverse structural applications.

Take the guesswork out and make instant, safe and accurate choices about which GRP grating product is best for your project. Interrogate the performance of our composite gratings in real-world scenarios by specifying your preferred product surface type (standard mesh, mini mesh or covered), clear span dimension, type of load, max load requirement and allowable deflection criteria (measured as a proportion of the span i.e. L/200 or 0.5%). Harness the transformative power of data today.

Find out how our market-leading composite products and applications are reshaping the industry.

Brochures

Designed, developed and manufactured by Dura Composites, unique d² Dura Grating offers a 33% weight…

Download

Brochures

High performance composite flooring and walkway solutions including trench covers, A2 fire rated decking, access…

Download

Brochures

Cost-effective, practical and safe GRP platforms, walkways, access structures & bespoke fabrications constructed from our…

Download

Brochures

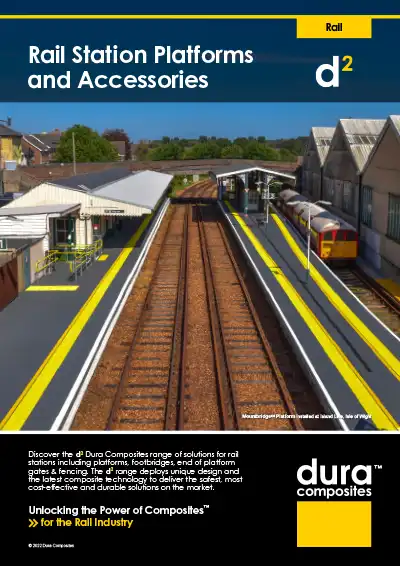

Discover the d² Dura Composites range of solutions for rail stations including platforms, footbridges, end…

DownloadOur BIM objects are hosted on NBS Source where they are available for use by architects, designers, engineer, contractors and specifiers.