Brochures

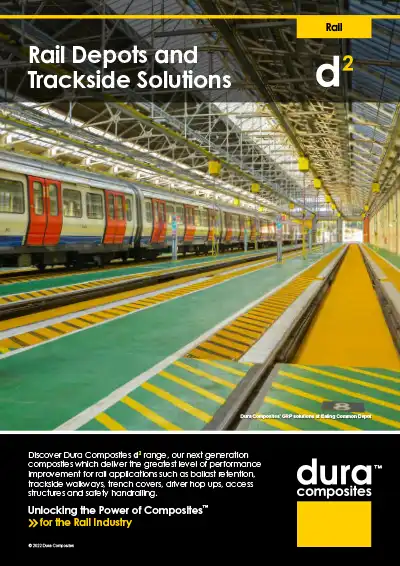

Rail Depots and Trackside Solutions

Discover Dura Composites d² range, our next generation composites which deliver the greatest level of…

DownloadRail | +44 (0) 1255 440291

General | +44 (0) 1255 446838

Sales Support | +44 (0) 1255 423601 (Option 5)

Transport | +44 (0) 1255 462567

Orange Train Wash is a small and easy-to-fit intelligent train cleaning system. It offers a new way to maintain your rolling stock which uses up to 98% less water than traditional systems. Manufactured using non-conductive composite technology, units can be installed in as little as 4 days, meaning setup is quick and efficient.

Empowered by Dura Composites as its manufacturing partner, the Orange Train Wash revolutionises how train exteriors are maintained with trailblazing cleanliness standards and radical environmental, carbon reduction, installation, productivity and cost saving benefits.

The modular semi-permanent (or permanent) Orange Train Wash system can be placed and used precisely where it’s needed – providing huge savings on civil engineering and operational costs and allowing CAPEX or OPEX procurement.

Manufactured using the sustainable d² range of safer, stronger, faster and proven GRP components with their unrivalled strength-to-weight ratio, our train wash units achieve a remarkable small and modular footprint, as well as increased safety by virtue of their non-conductivity.

Clients can access a one-stop shop for the design, supply and installation of the enabling Orange Train Wash infrastructure, including the substructure, safety walkway and patent-pending Envirosump liquid catchment system.

The wash utilises 85º deionized water through 60 water jets and powerful air blades and brushes which eliminate the need for additional chemical usage and ensure a thorough and eco-friendly clean. Sensors signal the wash system to retract to allow the clear passing of trains not due to be cleaned. Water temperature is maintained at 20° between washes, meaning winter conditions won’t disrupt your train cleaning programme.

Dura Envirosump is a Network Rail compliant structural liquid catchment system, with seamless integration into existing track and walkways, and a high level of adjustability to overcome the complexity of varying ballast heights. This system is compatible by design with the Orange Train Wash.

Explore our solutions and services to help you build resilient, greener and safer infrastructure.

Brochures

Discover Dura Composites d² range, our next generation composites which deliver the greatest level of…

Download

Brochures

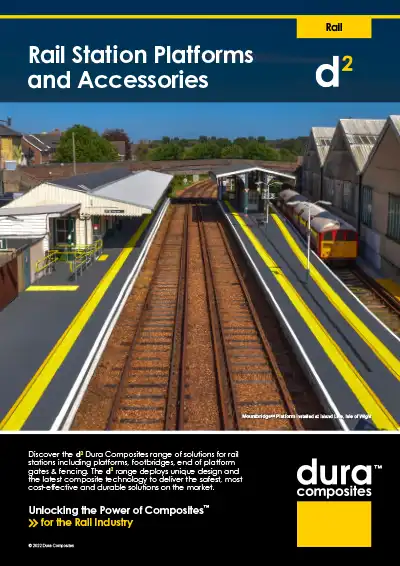

Discover the d² Dura Composites range of solutions for rail stations including platforms, footbridges, end…

Download