Our products provide an anti-slip, fire-tested and load-tested solution for stadiums and arenas that negates the need for the continual replacement of plywood flooring.

Our high quality and corrosion-resistant Glass Reinforced Polymer (GRP) products provide an anti-slip, fire-tested and load-tested solution for stadiums and arenas that negates the need for the continual replacement cycle that’s so common with plywood flooring. Unlike GRP, plywood is highly susceptible to ingress of water which causes delamination and degradation of the product. The open cell nature of plywood means that water absorption occurs at different rates from panel to panel, making product performance and ultimate failure rates hard to predict. By contrast, our GRP is closed-cell, anti-slip and weathers at a consistent rate over its expected 60 year lifecycle without the loss of significant strength. It is workable with standard hand power tools and is perfect for demanding stadium and arena applications where heavy footfalls are common.

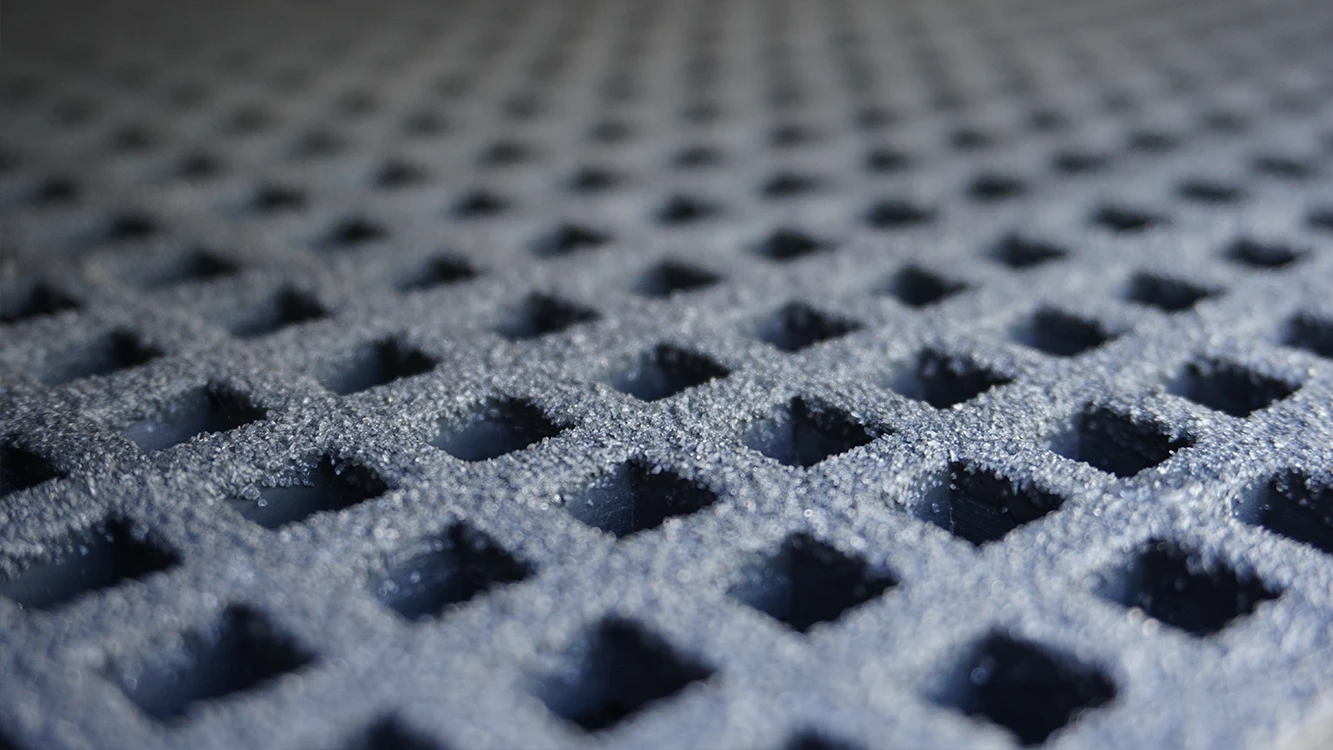

We offer pultruded d² Dura Slab and moulded d² Dura Grating products, both of which offer extremely low life cycle costs due to their maintenance-free, corrosion-resistant and impact-resistant characteristics compared with traditional materials. As shown below, we have designed our latest pultruded products to integrate easily into your existing flooring and walkway module designs, as a direct replacement for plywood.

Putting GRP to the Test for Stadium Environments

Our latest GRP innovations are purpose-designed for the stadium and arena market and our products are able to meet a range of stringent testing criteria. If you have a project which requires technical support with specific parameters for seating areas, landing, concourses or decks, we have a comprehensive range of testing information available to ensure maximum safety for your project. Key tests vary by product type, but can include:

- Fire Testing to BS476 Part 7 Class 1

- Fire Testing to EN13501 Bfl-S1

- Anti-slip testing

- Flare Resistance

- Point Load Live Tests

- Pre & Post Flare Test Exposure

- Hot Nut Test to BS4790

- FEA Design Analysis

Product Selector (Moulded vs Pultruded)

We employ two main processes for the production of our GRP walkway solutions – moulding and pultrusion. Both processes use a combination of resin and pure glass fibres to produce ‘thermoset’ products, which when fully cured; are stable and cannot be re-shaped other than by machine processes. Moulded panels (d² Dura Grating) are formed of a single piece construction with bi-directional load-bearing properties, whilst pultruded panels (d² Dura Slab) offer higher strength properties which are uni-directional. Our product selector will allow you to discover and compare which of our products are most suited to your application based on individual needs and specifications. It also gives a brief comparison versus plywood.