Brochures

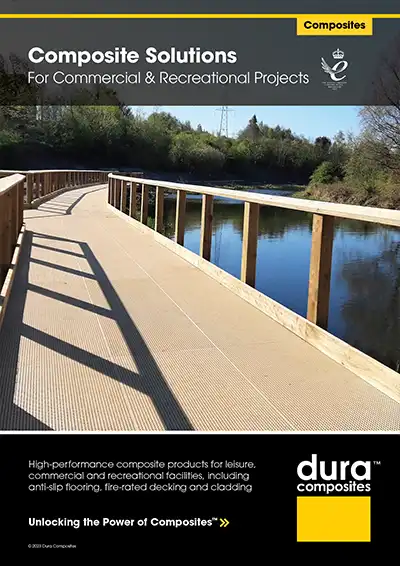

Composite Solutions for Commercial & Recreational Projects

High-performance composite products for leisure, commercial and recreational facilities, including anti-slip flooring, fire-rated decking and…

Download

General Sales | +44 (0) 1255 446838

Sales Support | +44 (0) 1255 423601 (Option 5)

Transport | +44 (0) 1255 462567

Rail | +44 (0) 1255 440291

Industral & Commercial | +44 (0) 1255 440290

High-Rise | +44 (0) 1255 446830

Decking & Cladding | +44 (0) 1255 440298

Marine | +44 (0) 1255 440297

| Length | A | B | C | D |

|---|---|---|---|---|

| Dimension Inputs | ||||

| Actual coverage (include edges) |

| Items | Units | Boxes | Box Price | Total |

|---|---|---|---|---|

| Sub-Total | ||||

| Free Shipping (UK mainland) | £0.00 | |||

| VAT (20%) | ||||

| Total | ||||

Experience a stunning deck transformation effortlessly and affordably! Our composite decking tiles are easy to install, forming a level, anti-slip surface that mimics traditional decking without the installation or maintenance hassles.

Versatile for any use, our composite timber decking tiles, made from UV-stable high-performance composite timber, add instant appeal to outdoor spaces. Perfect for quick rejuvenation or creating temporary seating areas, these tiles interlock seamlessly without the need for screws or bonds.

Whether for domestic or commercial spaces, Dura Deck Tile is a superior investment with a patented design. The tiles can be added to any firm, flat surface for an instant, hassle-free transformation.

Transform your outdoor space into a beautiful, ready-to-use decked area in minutes without the need for a professional landscaper, complicated bearers or costly fixings. Enjoy maximum impact with minimal effort and cost!

Save up to 50% compared to traditional decking costs, as no expensive substructures or professional services are required. The tiles interlock seamlessly, creating a practical and professional-looking anti-slip surface. Ideal for overlaying existing areas, Dura Deck Tile is a cost-effective and hassle-free solution for a beautiful decked space.

In stock and available to buy today with FREE SHIPPING

Our tiles are double the length of competitor products for a more realistic deck effect and half the install time.

The fantastic wood effect surface features a unique finish that allows the product to achieve low slip potential in dry or wet conditions.

Our unique 360° outer armour ensures strength, protects against staining, resists fading and effectively manages contraction and expansion.

The top surface of our decking tiles are created with up to 87% recycled materials, guaranteeing an environmentally conscious product that champions sustainability.

We offer complete end-to-end delivery, from fully insured project design and unique product supply to full turnkey installation using our specialist partner contractors.

Brochures

High-performance composite products for leisure, commercial and recreational facilities, including anti-slip flooring, fire-rated decking and…

Download

Brochures

Easy to install 2ft x 1ft fast-fit interlocking outdoor decking tiles that turn any flat…

DownloadUnlike our competitors our decking boards are created with up to 87% recycled materials, guaranteeing an environmentally conscious product that champions sustainability. That’s why we were the first composite manufacturer to be recognised by the FSC® Chain of Custody certification, awarded to companies that can track and document FSC® certified materials through the production process – supporting sustainable forestry and forest management. In addition, due to the 25+ year service life of our decking, we are cutting out the constant use of natural materials for exterior projects. This is helping to create a better, more eco-friendly environment for everyone!.