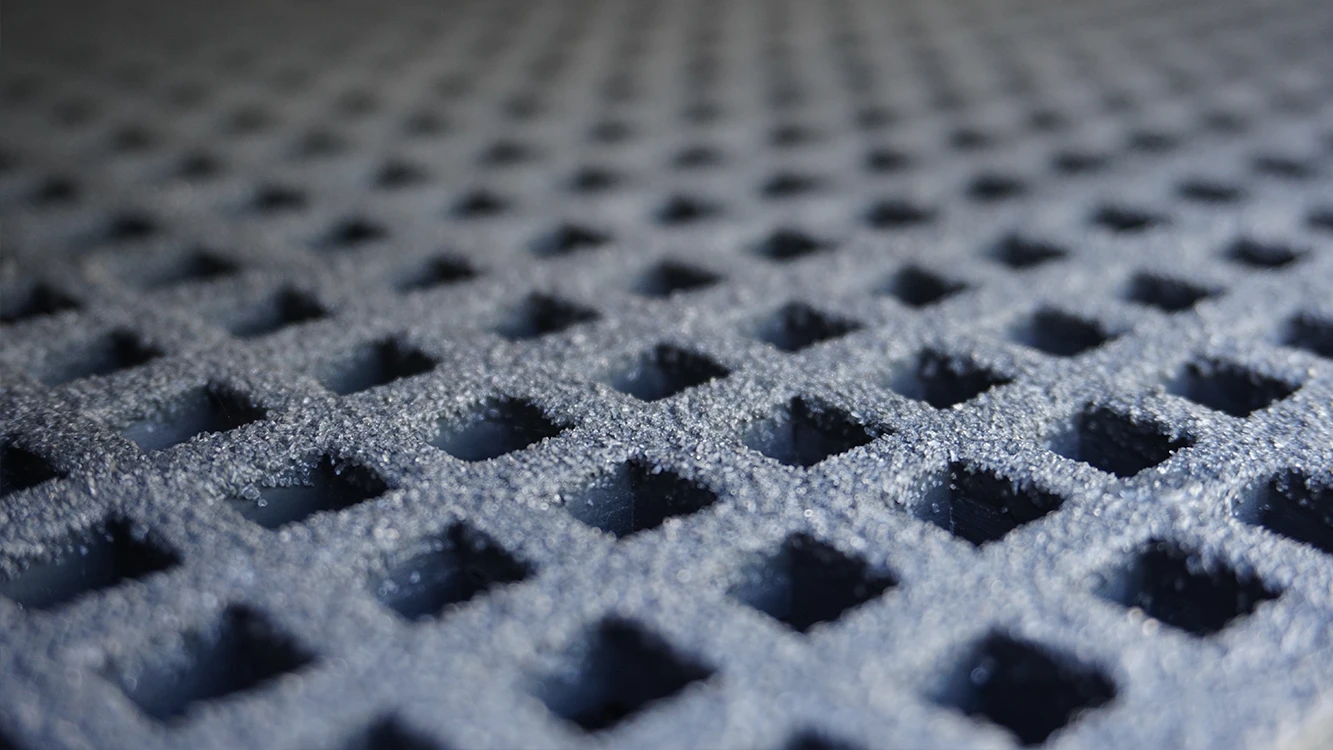

Raised bund flooring with the lowest embodied carbon available.

In this project, one of the existing bunds had reached the end of its service life and a full-scale refurbishment (including the associated transformer plant equipment) was needed.

Requiring a raised platform and a surface that allowed for the flow of liquids to the sump, contractor Adler & Allan, approached us to provide a full turnkey solution of survey, design and supply to meet their needs.

Leaning on our in-house design specialists, they choose our d² Dura Grating Standard Mesh, which was installed on our raised pedestals, to meet their free-flow specifications. With 33% less embodied carbon than other standard mesh grating panels that are 38mm thick, our grating helped this client towards their net zero objectives.

Unique design aids visibility below the grating.

The unique d² Dura Grating design also allows for improved visibility of the substructure below, offering a clear view of any leakages such as transmission oil from a much wider range of angles than were previously achievable.

With flexibility in design, the grating can easily be taken up, moved and adapted, if there was any future maintenance or changes needed. The anti-slip, non-conductive, fire-resistant grating panels, enabled the client top enhance safety on site for all personal, and by selecting our pre-cut panel option, the 3 metre by 1 metre sheets of d² 38mm Standard Mesh provided the most efficient pedestal spacing, with no need for panel-to-panel joining, reducing deflection and further enhancing safety.

With our d² Dura Grating, already significantly lighter than the industry standard, the pre-cut panels allowed for an even larger overall carbon saving, with easier manoeuvrability, significant savings on installation time, transport costs and labour, and little to no waste on site. With a 25 year warranty and long design life, we were able to futureproof this substation for generations to come.