Data derived from real testing not theoretical assumptions.

We can help support your design services across all phases of the project lifecycle by providing detailed technical specifications for our award-winning product range. Our load and deflection data is available to help you make decisions based on data derived from real testing not theoretical assumptions, to ensure maximum safety for your project. Use our GRP data analysis tool known as ‘Power of Composites’ to help eliminate products which do not meet your specified Load, Span or Deflection criteria.

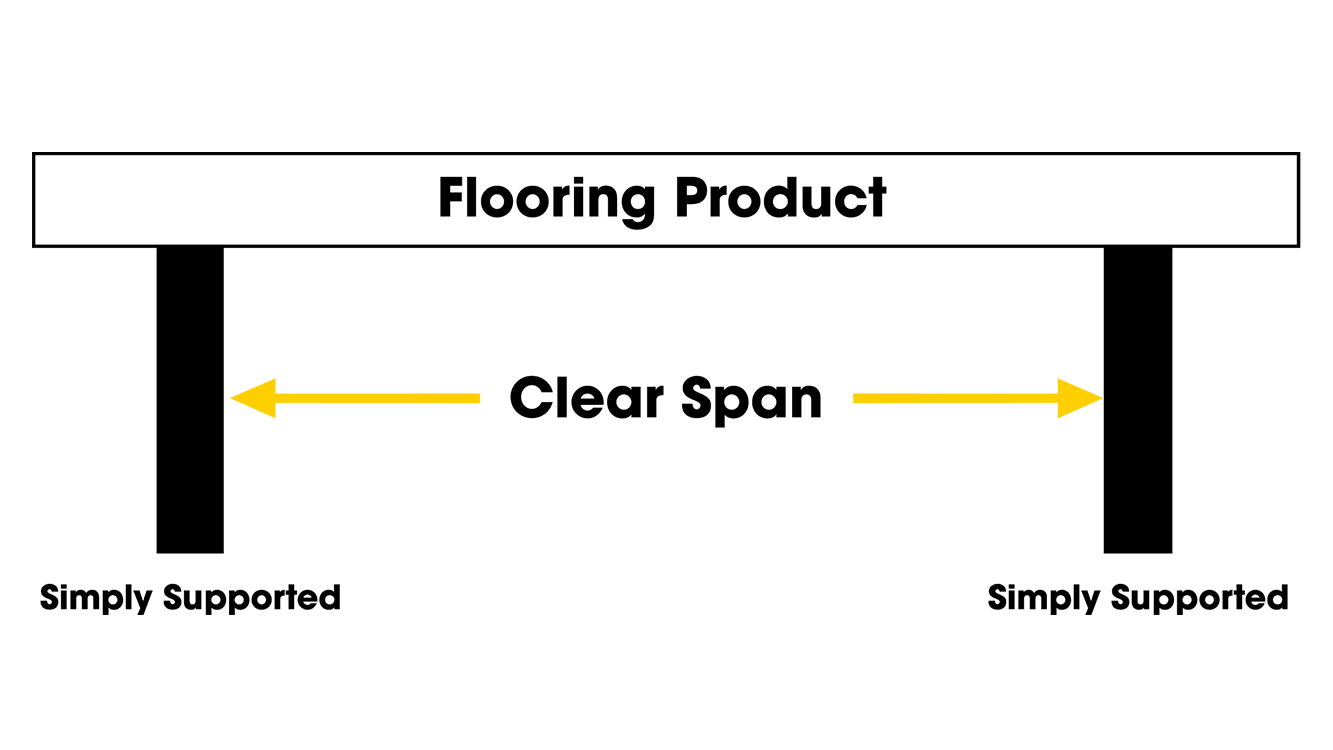

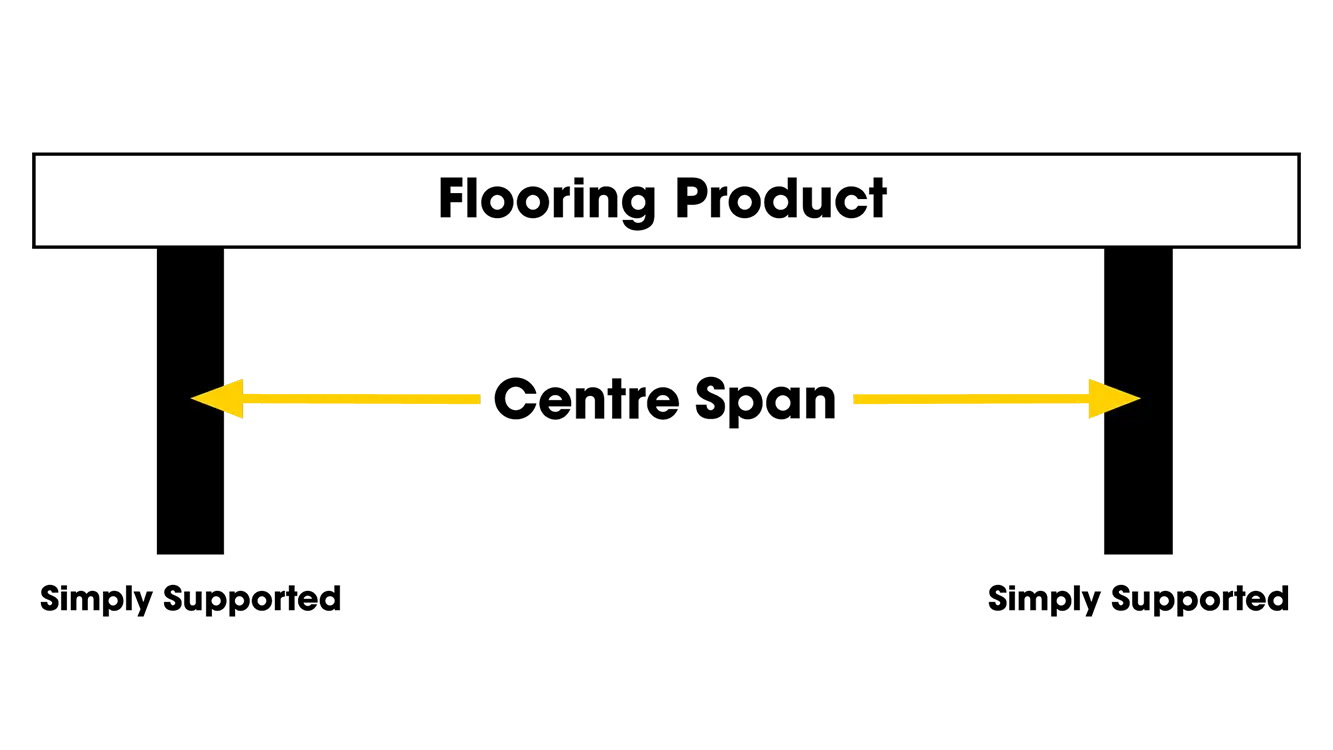

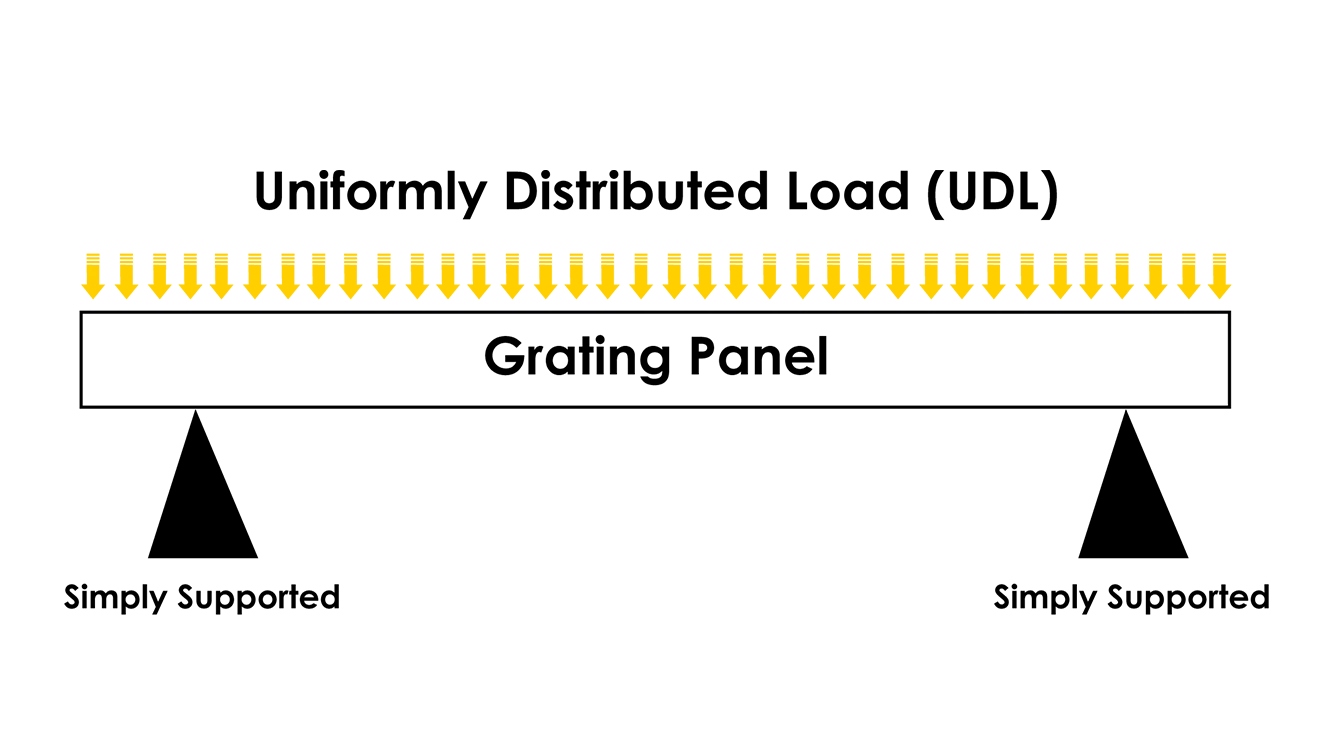

Understanding Spans

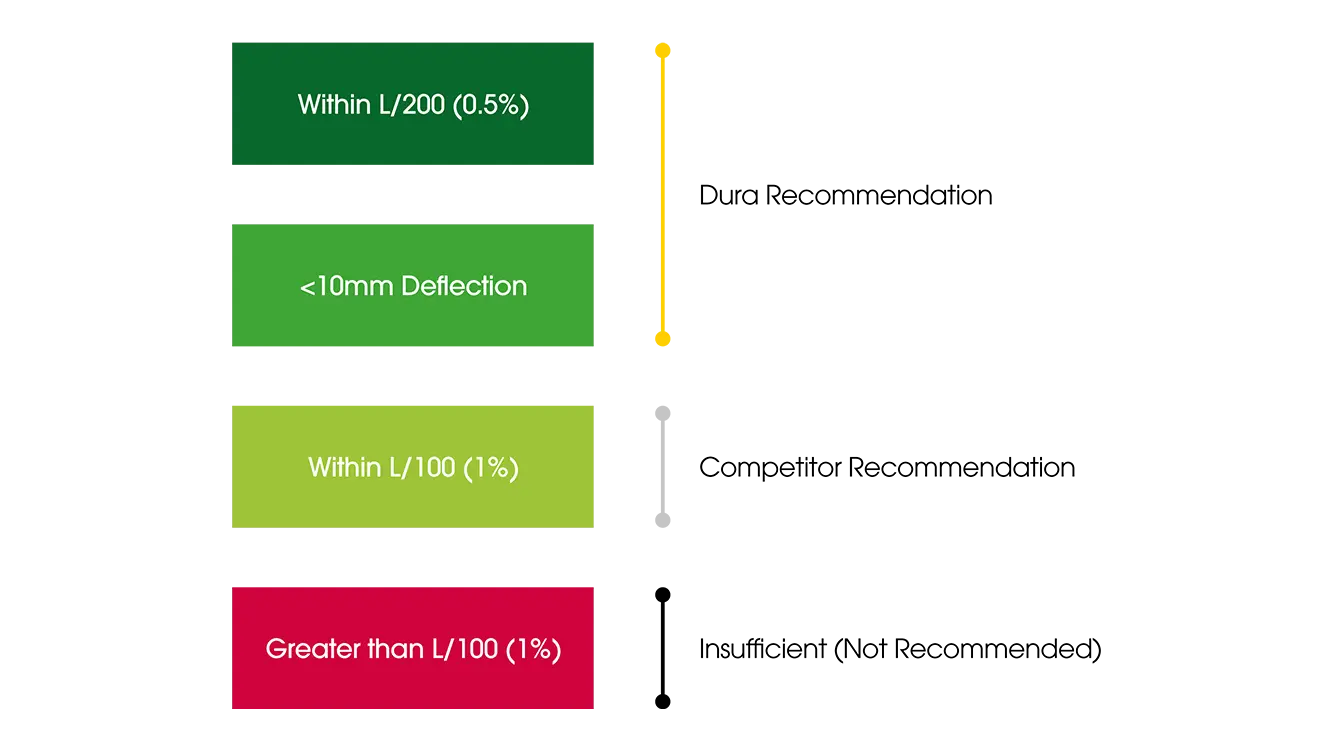

Understanding Load & Deflection

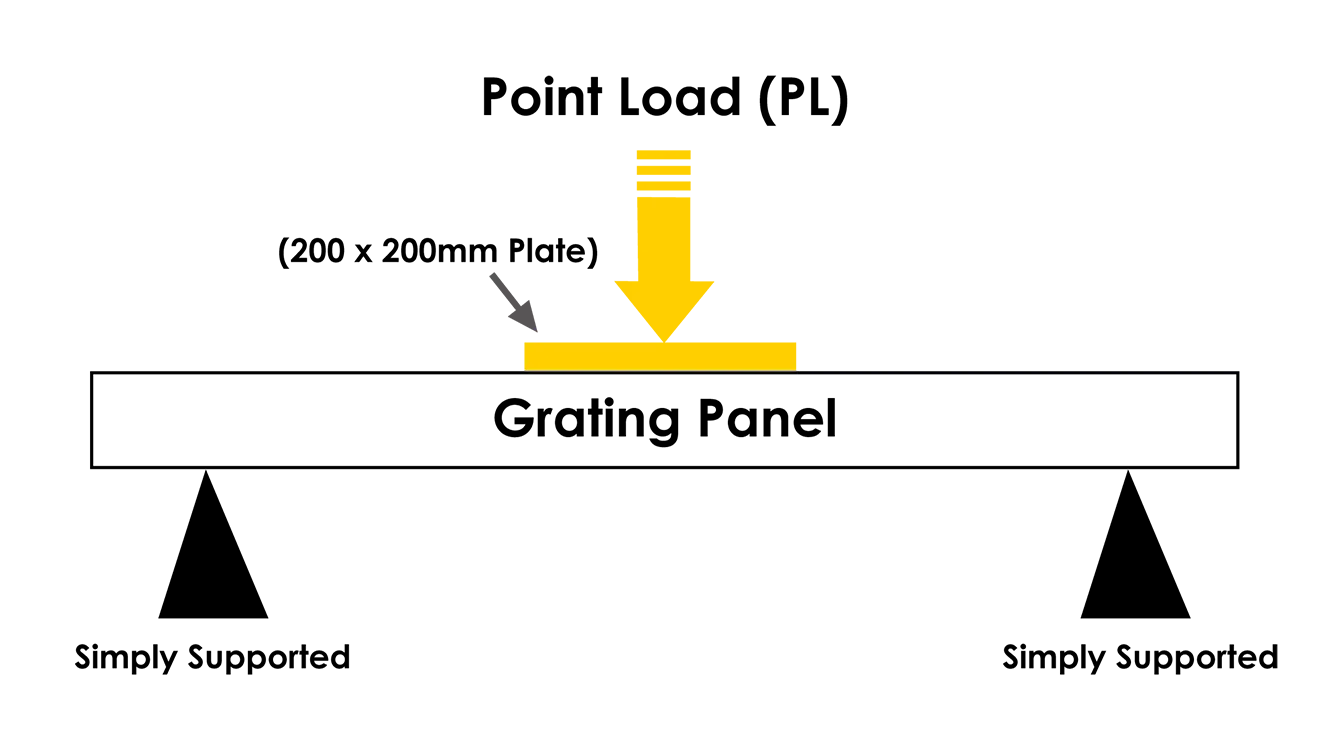

Appropriate Loads