Innovative GRP access solutions for a sustainable future.

Founded in 1862, Simpsons Malt is an independent, fifth-generation family-owned business. After more than 155 years in business, Simpsons Malt continues to invest in state-of-the-art equipment, most notably for its pioneering green energy project which replaces natural gas with a biomass and high-voltage electric boiler system, powered by locally sourced sustainable woodchip and surplus North Sea wind energy with the aim of delivering an 80% reduction in carbon emissions.

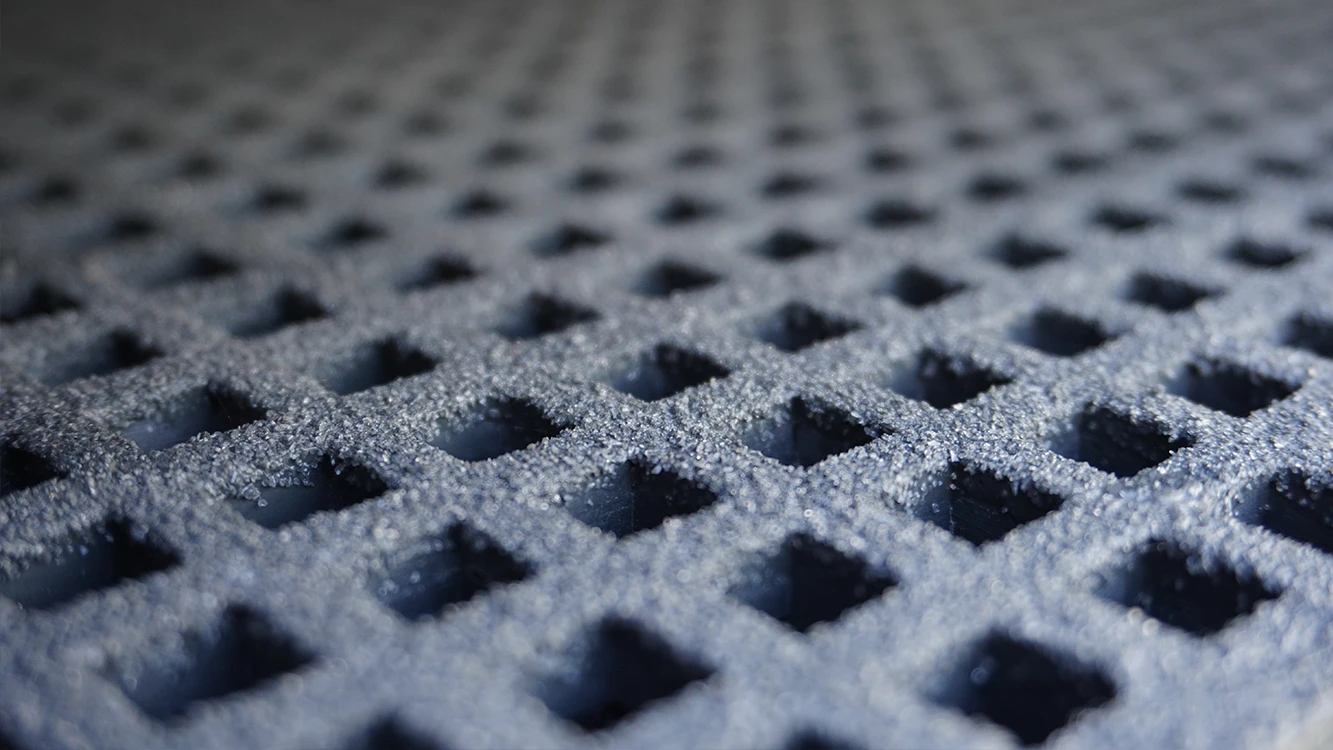

To ensure safe, durable, and low-maintenance access to the new renewable energy infrastructure, the project features GRP access structures made from d² Dura Profile components, with d² Dura Grating used for landings and stair treads. These materials offer superior durability, corrosion resistance, and sustainability, making them ideal for industrial environments exposed to heat, moisture, and chemicals.

d² Dura Profiles incorporate intelligent design optimisation and are manufactured to exceed the E23 Grade of BS EN 13706 by up to 50%. This allows for smaller, fewer components to be used without compromising strength, improving project efficiency and reducing costs. Additionally, the d² profiles used at Simpson’s Malt are engineered using less raw material, achieving up to 50% lower embodied carbon compared to alternative profile solutions. At the end of their lifecycle, the structures can also be repurposed, reinforcing their sustainability credentials.