Overcoming the Challenges of Steel Grating Systems

J Murphy and Sons was awarded a £21.8m contract for the construction of the onshore substation, with WSP providing civil design support. Whilst steel punched grating would have traditionally used in transformer bunds in a project like this to restrict oxygen flow and help to suffocate fires, this system has several practical limitations including:

- Complex Earthing Requirements: Every steel panel must be daisy-chained and earth-linked. These connections require inspection every 12 months, increasing maintenance overheads.

- Installation Challenges: Steel panels often suffer from poor installation practices, leading to misfitting components. This affects performance and longevity.

- Short Life Span: The durability of steel gratings is sometimes questionable, necessitating frequent replacements.

- Difficult Inspection: Concealed earth connections are located on the underside of panels, making access challenging. Shallow bunds exacerbate this issue, limiting inspection and maintenance.

Given these issues, Race Bank Substation explored different solutions to improve performance and safety. In this instance, polyester, vinylester isophthalic or orthophthalic GRP variants were also not suitable as they could not satisfy the fire requirements, so Dura was engaged to provide an alternative.

Dura Composites’ Phenolic GRP Solution for Substations

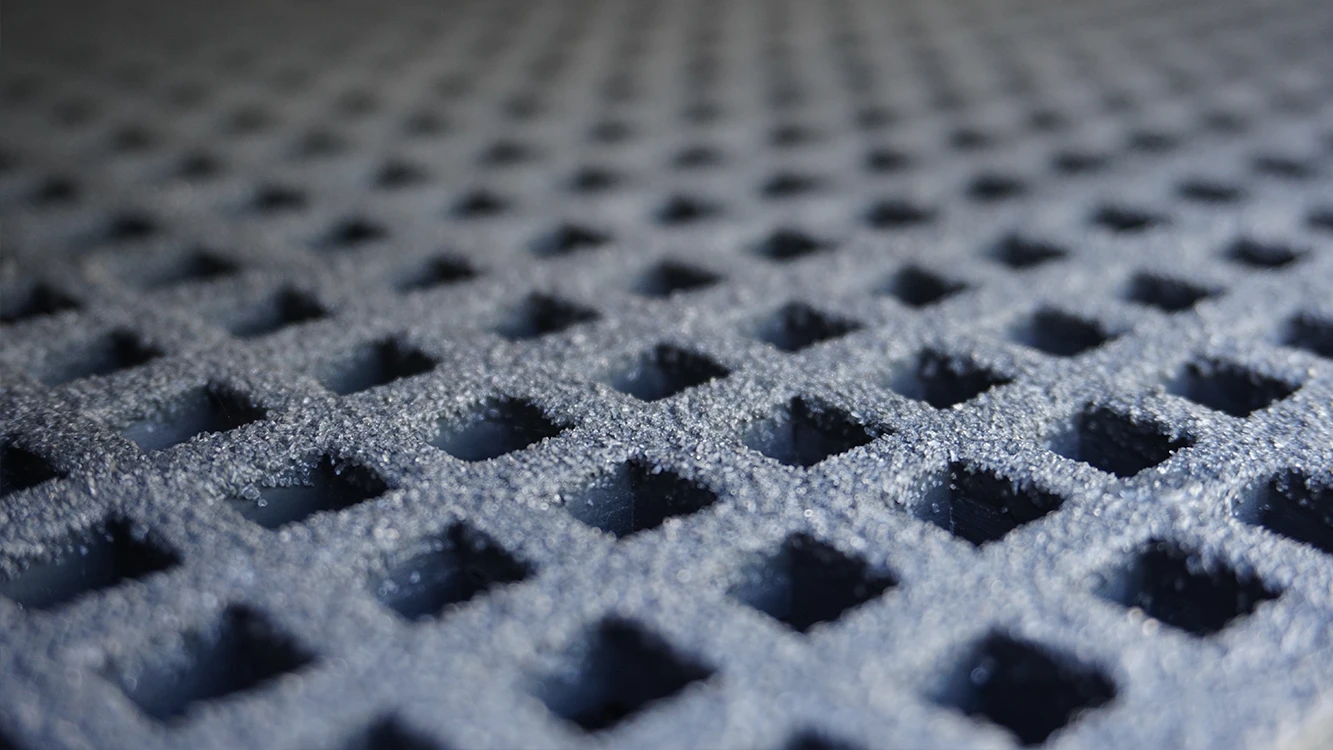

Dura Composites provided a phenolic GRP Dura Grating system to address the shortcomings of steel grating. This innovative solution was tailored to the substation’s requirements, leveraging the unique properties of phenolic GRP and a specialised installation method.

- Fire Resistance: As demonstrated by USCG E-119 testing, Phenolic GRP will not liquefy during a fire. The gratings were subjected to temperatures of 927°C for 60 minutes without failure.

- High Performance Standards: The phenolic GRP grating complied with the following safety and performance standards:

BS 476 Part 7 Class 1: Surface Spread of Flame

BS 476 Part 6 Class 0: Fire Propagation

BS 6853: 1999 Annex D8.4: Smoke Emission Test

ASTM-E84: Flame Index (10), Smoke Index (135)

ASTM-E119: Fire Resistance

ASTM-D635: Zero Burn Rate

ASTM-D2394-2011: Static Slip Resistance (0.93), Dynamic Slip Resistance (0.82)

- Durability: Phenolic GRP exhibits superior durability, reducing the need for frequent replacements and lowering long-term maintenance costs.

- Simplified Installation: The GRP panels were mounted on steel pedestals, accommodating screed falls. Pedestals were securely fixed to the screed floor using concrete anchors, ensuring robust and stable installation.To enhance fire mitigation further, (although not utilised in this instance), a 300mm layer of 20mm stone is sometimes installed alongside the grating, serving as a flame-extinguishing medium.

A Smooth Installation

To streamline installation and minimise disruption, Dura Composites provided bespoke solutions tailored to the specific needs of the project:

- Labelled Panels: GRP panels were labelled according to bund type (e.g., Transformer, Shunt Reactor, DRC, Auxiliary) to facilitate efficient distribution.

- Palletised Bundles: Each bund type was palletised separately for organised delivery to installation locations.

- Pre-Packaged Fixings: Fixings were individually packaged and sorted by bund type, reducing installation time and complexity.

Benefits of the Dura Grating System

The phenolic GRP solution delivered by Dura Composites several critical advantages:

- Enhanced Fire Safety: Unlike some standard GRP panels, phenolic GRP does not liquefy during fires, preserving drainage systems and reducing fire damage risks.

- Reduced Maintenance: Simplified earthing requirements and durable materials eliminate frequent inspections and replacements.

- Improved Installation: Pre-packaged and labelled components expedited the installation process, reducing labour and errors.

- Longer Lifespan: Phenolic GRP’s resistance to environmental and mechanical stress ensures a longer operational lifespan compared to steel grating.