Committed to reaching net-zero by 2050.

As part of the The Freight and Passenger Safety Improvement Programme (FSIP), Dyer & Butler, with its client Network Rail, have been delivering safer, sustainable walkways for freight operating staff across eleven sites in Kent, Sussex and Wessex.

Dyer & Butler part of M Group Services, are committed to reaching net-zero by 2050 and achieving a 50% reduction by 2030. So finding ways to make their operations more sustainable was crucial to their aims.

Which is where we came in…

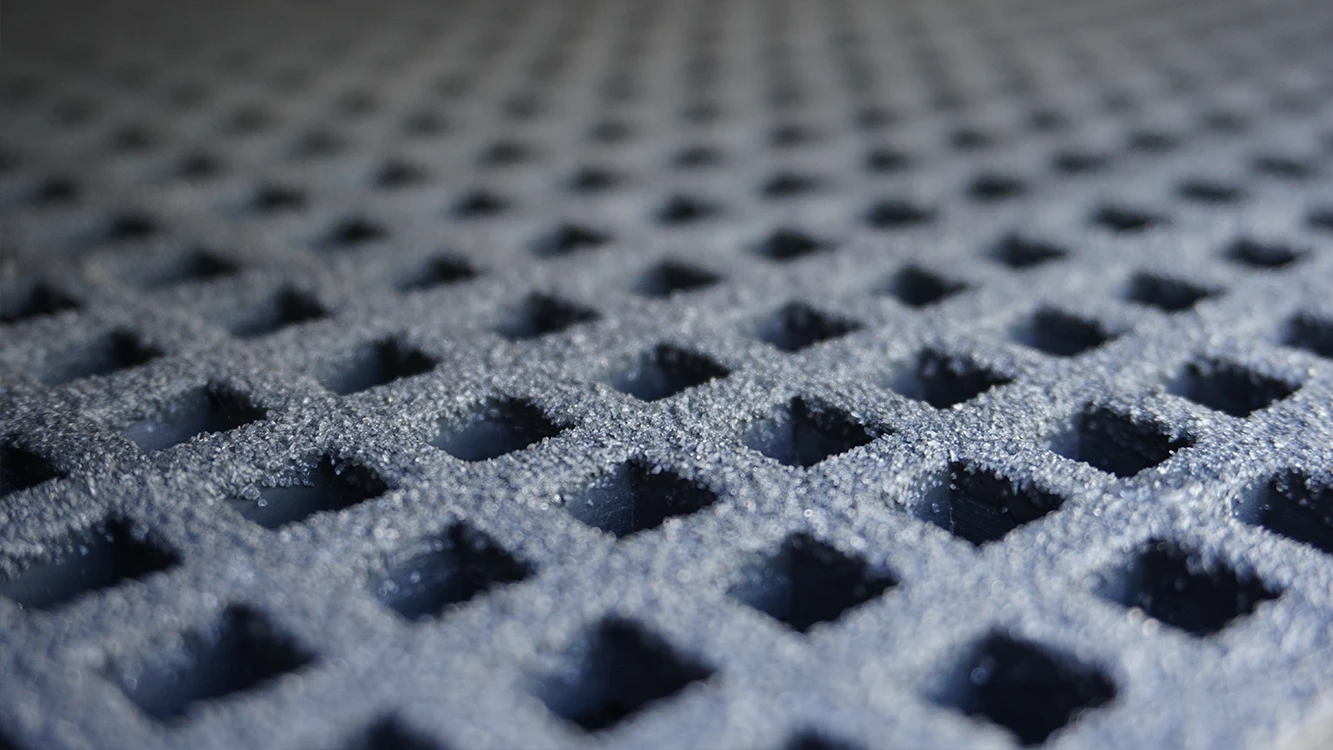

By choosing to use our GRP grating panels for the project, they not only enabled freight operating staff to walk safely within the network infrastructure, but they also took a giant stride towards their net-zero targets.

The panels are re-engineered from industry standard panels, creating a lighter, low carbon alternative. Each d² Dura Grating consumes 47% less material than the previous standard panels, which has resulted in a whopping material saving of 34,195kg across the project and 130t reduction in embodied CO₂e.

Early Engagement

By working with us early in the project planning process to have the panels made to the exact sizing requirements of the walkway, reducing the need for cut-offs and surplus materials on site. This has eliminated 7.7 tonnes of waste, which equates to a carbon saving of 29 tCO₂e – the equivalent to driving around the circumference of Earth four times.

Social Value

Using the Rail Safety and Standards Board’s (RSSB) Rail Social Value Tool, this carbon saving has resulted in £41,168.00 of social value, representing the proxy value of the economic cost to the UK government to mitigate the impacts of the 159 tCO₂e that would have been emitted into the atmosphere.