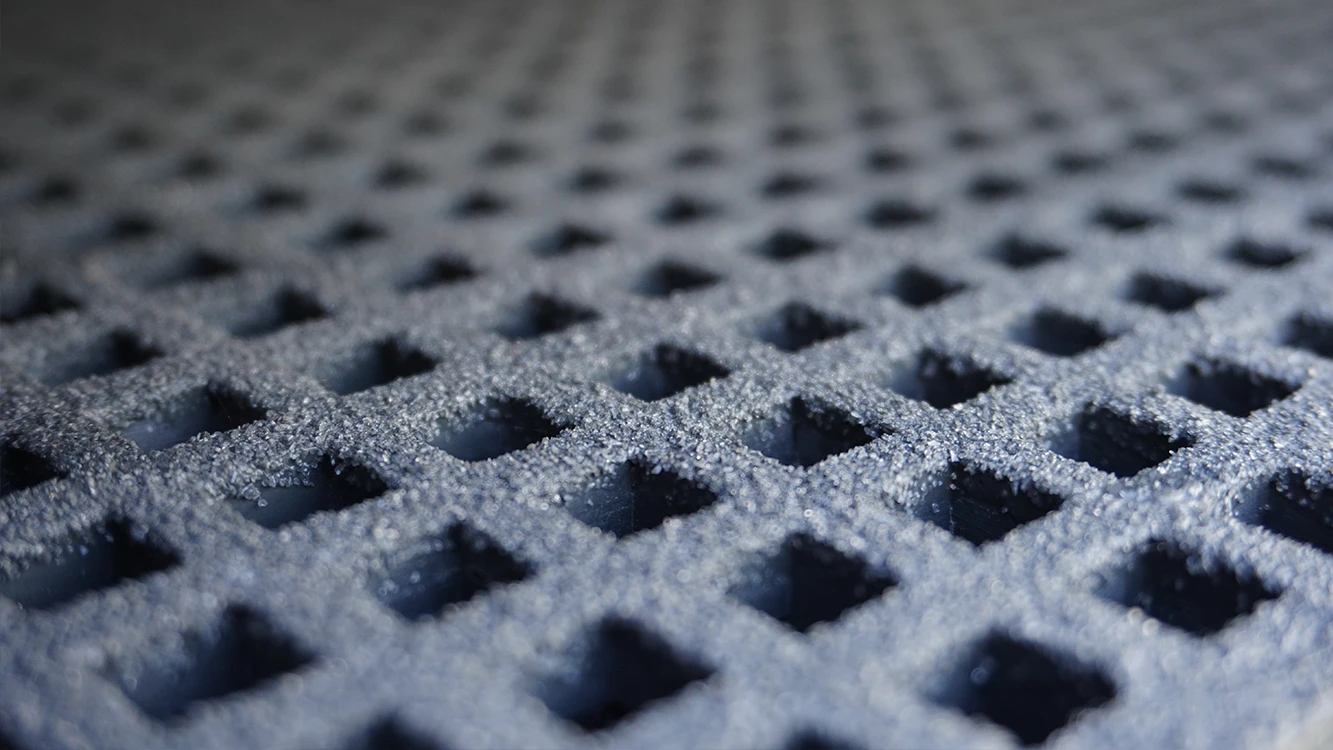

Fabricated from non-conductive and non-corrosive GRP.

First Light Fusion is an Oxford-based research company which believes that its unique projectile fusion approach offers the fastest, simplest and cheapest route to commercial fusion power. The company’s goal has been to achieve fusion by using shockwaves, inspired by the pistol shrimp, which clicks its claw to produce a shockwave known as inertial confinement. In May 2022, the company successfully achieved fusion, with the UK Atomic Energy Authority (UKAEA) independently validating the achievement.

Central to the company’s operations is Machine 3, an electromagnetic launch device that allows projectiles to be launched at different velocities. Machine 3 has a structure which was fabricated from non-conductive and non-corrosive Glass Reinforced Polymer (GRP) by composite fabrication experts Dura Composites, and is capable of discharging 200,000 volts and in excess of 14 million amperes within two microseconds. This ‘shot’, which is equivalent to around 500 simultaneous lightning strikes, fires a projectile at a small target containing a tiny amount of fuel, collapsing a cavity and superheating the plasma to achieve fusion.

The structure was fabricated from Dura Composites’ GRP Dura Profile range, which includes Angle, Channel, Beam, Box and Tube sections. Weighing significantly less than steel, Dura Profile offers equivalent performance for considerably less weight. This results in major cost savings due to more economical transportation, handling and on-site fitting. It is fast becoming the material of choice for work platforms, ladders, handrailing, cable trays, flow sub-structures and more, thanks to its corrosion-resistant, high strength, low weight, non-conductive and UV resistant characteristics.