Low carbon GRP riser flooring and innovative hanging AHU gantries

Built by Skanska, 20-22 Ropemaker Street is a mixed-use commercial scheme, worth £240 million which occupies a prominent corner site just north of Moorgate Station in London. Occupiable office space covers 22 floors, with five accessible roof terraces. Three basement levels are provided for retail servicing, plant, facilities management, cycle and shower facilities.

The building’s four cores are positioned along the rear northern elevation, with the larger cores being slip formed and the slimmer satellite core predominantly accommodating services. The slim core structures were jump-formed, with the concrete contractor always working three floors below the steel erection, using the completed steel frame for stability.

Internally and above ground floor, the steel frame consisted of fabricated beams supported by CHS columns. The beams feature bespoke web openings to accommodate the building’s services. The d² Dura Riser system was configured to seamlessly interface with the substructures that made up the edges of these openings and specialised connection details were designed that allowed Dura Composites’ installation team to fit to the fire protected structural members, whilst maintaining the 120 minute fire rating.

In-built adjustability to overcome any variation in M&E services

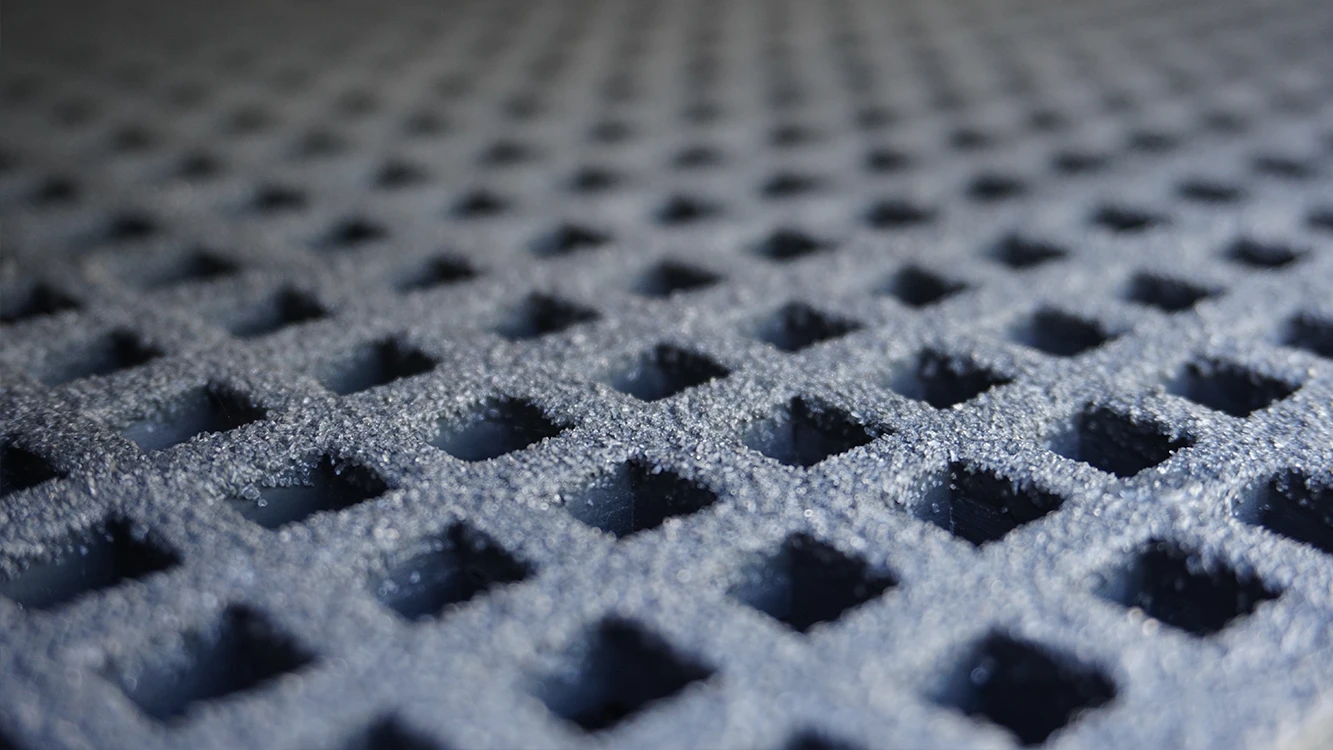

The d² Dura Riser system utilised its built-in adjustability, to overcome any variation in the M&E services’ final positioning. The system has fire ratings of Class A1 on substructure and Class B for the gratings.

This project benefited from enhanced safety measures by selecting a grating that complied with the 20mm Ball Fall Test and proven Live Load testing. The d² products impressive reduction in carbon vs traditional materials, aligned seamlessly with the project’s sustainability objectives. Notably, our riser void covering solutions ensure safety from the moment of installation, eliminating the need for scaffold handrails, netting, or timber shuttering that would have incurred additional costs to the project.

Rooftop plant access decks and hanging gantries

In addition to the riser flooring, Dura Composites also installed hundreds of square metres of GRP mini mesh to form rooftop access decks. These were paired with bespoke light weight GRP access structures that are very low upkeep due to GRP’s resistance to weathering and corrosion. This package therefore enabled the safe future maintenance of plant equipment.

Another stand out feature of this project was the designing and fabricating of hanging gantries to house air handling units in the ceiling recess, using our patented d² Dura Riser system lightweight steel framing and GRP walkways . Thanks to our Design & Engineering capability, we were able to simulate and provide a full design verified by full calculations, and backed up by on site testing of the relevant connections, ensuring they could withstand the maximum factored load imposed by the drop rods used. The gantries allowed the reclamation of space in the mezzanine lobby area for vital plant without losing any of the building’s valuable footprint.