In the water treatment and utilities sectors, steel has long been the go-to material for raised walkways, platforms, trench covers and access structures. Its strength and familiarity make it a natural choice. However, the growing demands for corrosion resistance, safety, sustainability, and reduced maintenance mean traditional materials like steel are no longer the most practical or cost-effective option.

Enter d² Glass Reinforced Polymer (GRP) Profiles and Grating — our advanced composite solutions designed to outperform steel in the harshest environments, while helping the industry meet sustainability targets.

What is d² GRP, and Why Does It Matter?

Our d² GRP range is engineered specifically for demanding industrial environments, including wastewater treatment plants, pumping stations, and utility infrastructure. Designed to tackle the challenges where steel often falls short, d² GRP offers significant advantages that can’t be ignored.

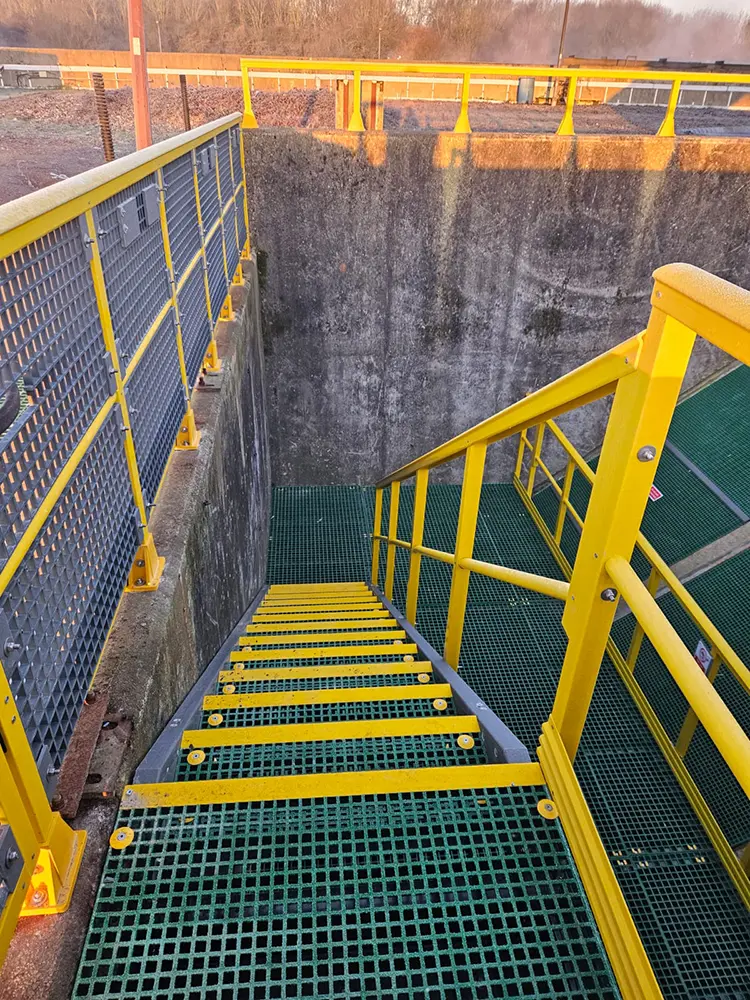

Our d² range is used to create a wide variety of infrastructure solutions, including access platforms, ladders and elevated walkways—each designed with longevity in mind to help futureproof your assets and support cost-effective, reliable facility performance.

In addition, we offer GRP Trough Lids. Fall Arrest and Chamber Covers that serve as a robust yet lighter-weight alternative to traditional steel Technocovers. Their non-corrosive properties make them ideal for harsh environments, while their reduced weight simplifies both handling and installation.

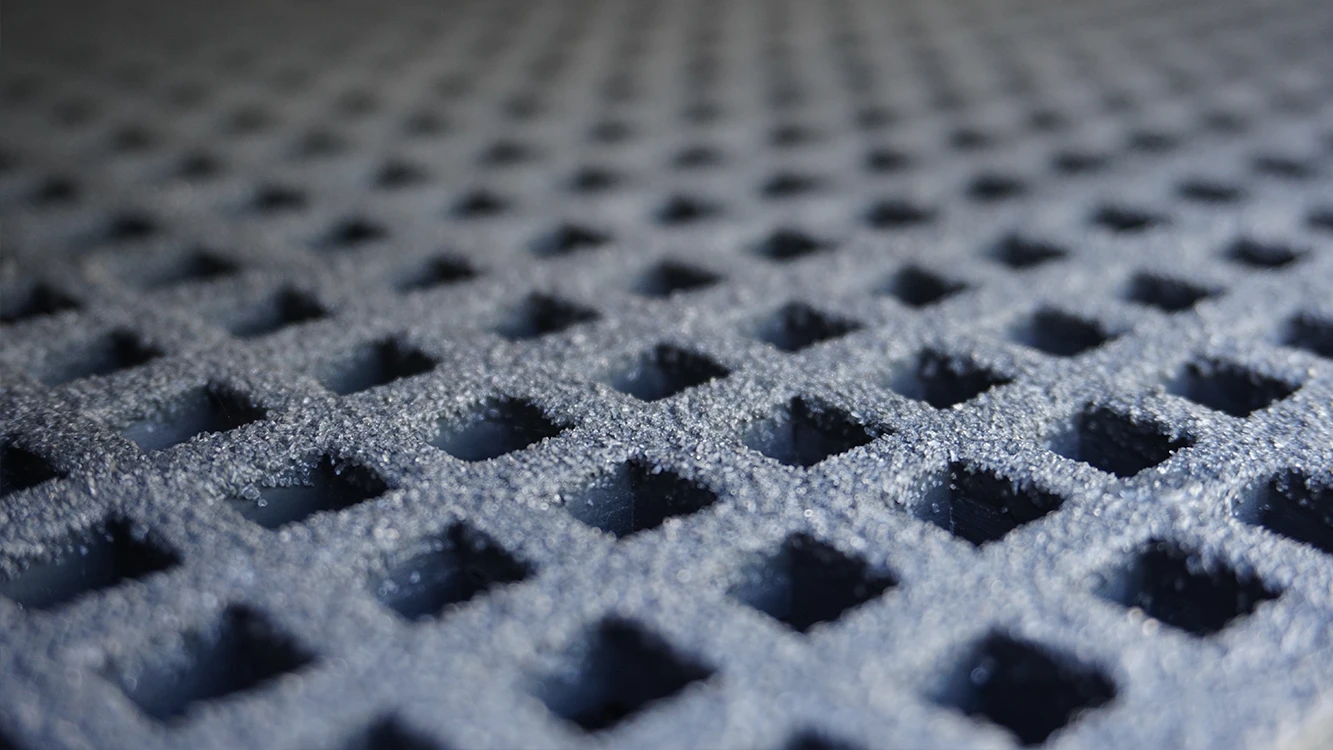

1. Superior Corrosion Resistance — Especially in H₂S-Rich Environments

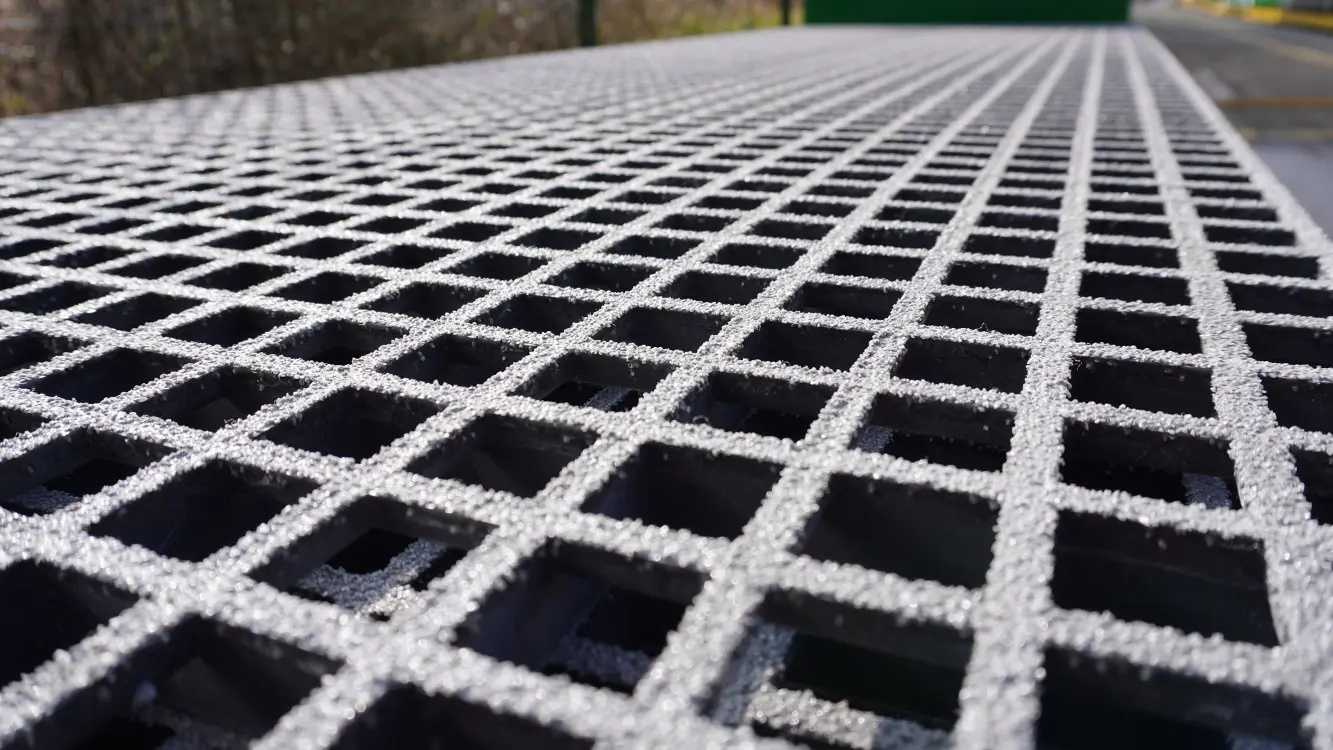

Corrosion remains the biggest weakness of steel in water and wastewater applications. Even galvanised or coated steel degrades when constantly exposed to moisture, sewage, and chemical gases such as hydrogen sulphide (H₂S) — a particularly aggressive compound found in anaerobic wastewater processes. Where required, we can supply low embodied carbon d² GRP products designed to resist exposure to hydrogen sulphide (H₂S), making them ideal for sewer and wastewater applications where this gas is commonly present.

That means, once installed, your walkways, trench covers, and access platforms stay safer for longer, with significantly less maintenance.

2. Strong Yet Lightweight — With Easier, Safer Handling

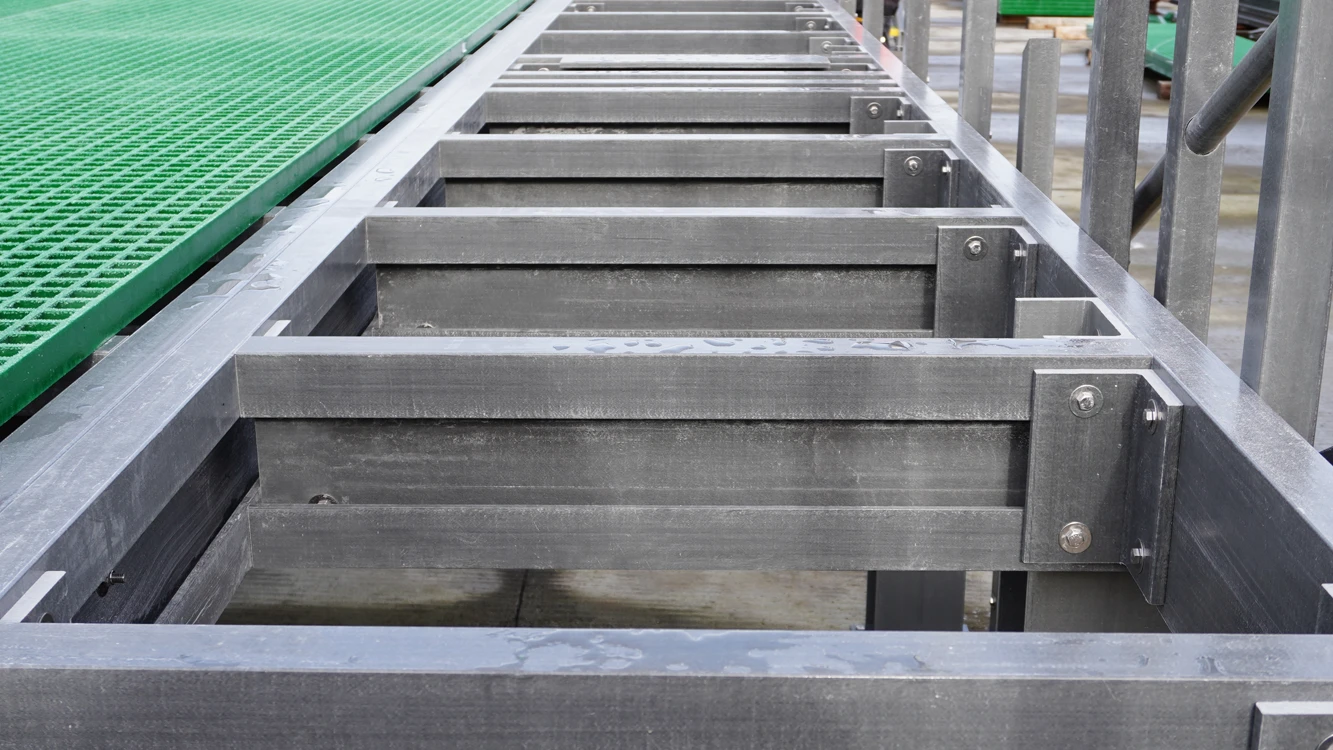

One of the most impressive features of d² GRP is its high strength-to-weight ratio. The innovative design is up to 33% lighter than standard materials, making it easier to handle, quicker to install, and often eliminating the need for heavy lifting equipment on site.

Despite its lighter weight, d² GRP can span longer distances and handle larger loads than traditional GRP or even steel in some cases — reducing the need for excessive supporting structures and lowering overall project costs.

3. Non-Conductive for Safer Working Environments

Steel conducts electricity, posing potential risks in water facilities where electrical systems are everywhere — from pumps and motors to control panels.

d² GRP is non-conductive, dramatically reducing the risk of electric shock, especially in wet environments. For the water industry, this added safety benefit is a game-changer.

4. Designed for a Sustainable, Low-Carbon Future

Sustainability is now a core focus for every industry, and the water sector is no exception. At Dura Composites, we’ve developed the world’s lowest carbon composite walkway systems — designed to help you meet your Net Zero goals without compromising on performance. Our d² range offers:

- Up to 33% less embodied carbon than traditional materials

- Closed-loop recycling and repurposing options

- Verified Environmental Product Declarations (EPDs) for easier Scope 3 reporting

- Since launch, our d² products have saved:

- Millions of kilograms of CO₂ emissions

- The equivalent impact of planting 700,000 trees and growing them for a decade — that’s over 300 football fields of forest!

- This makes d² GRP the greenest choice for sustainable water industry infrastructure.

5. Built for the Circular Economy

Unlike steel, which often becomes scrap at end-of-life, our d² GRP products can be recycled and repurposed. We actively support customers by taking back GRP waste from site installations, ensuring minimal environmental impact and supporting the circular economy.

6. Full Technical Support and Carbon Data for Compliance

We understand the pressure on contractors and water companies to report accurately on carbon impact. That’s why we provide:

- Embodied Carbon data

- Independently verified EPDs

- Technical resources to support design, installation, and reporting

- This helps you simplify compliance, improve Scope 3 emissions reporting, and make confident material choices that stand up to scrutiny.