If you’re wondering what the difference is between Mini Mesh and Micro Mesh fibreglass (also commonly known as GRP) grating, then Dura Composites can help.

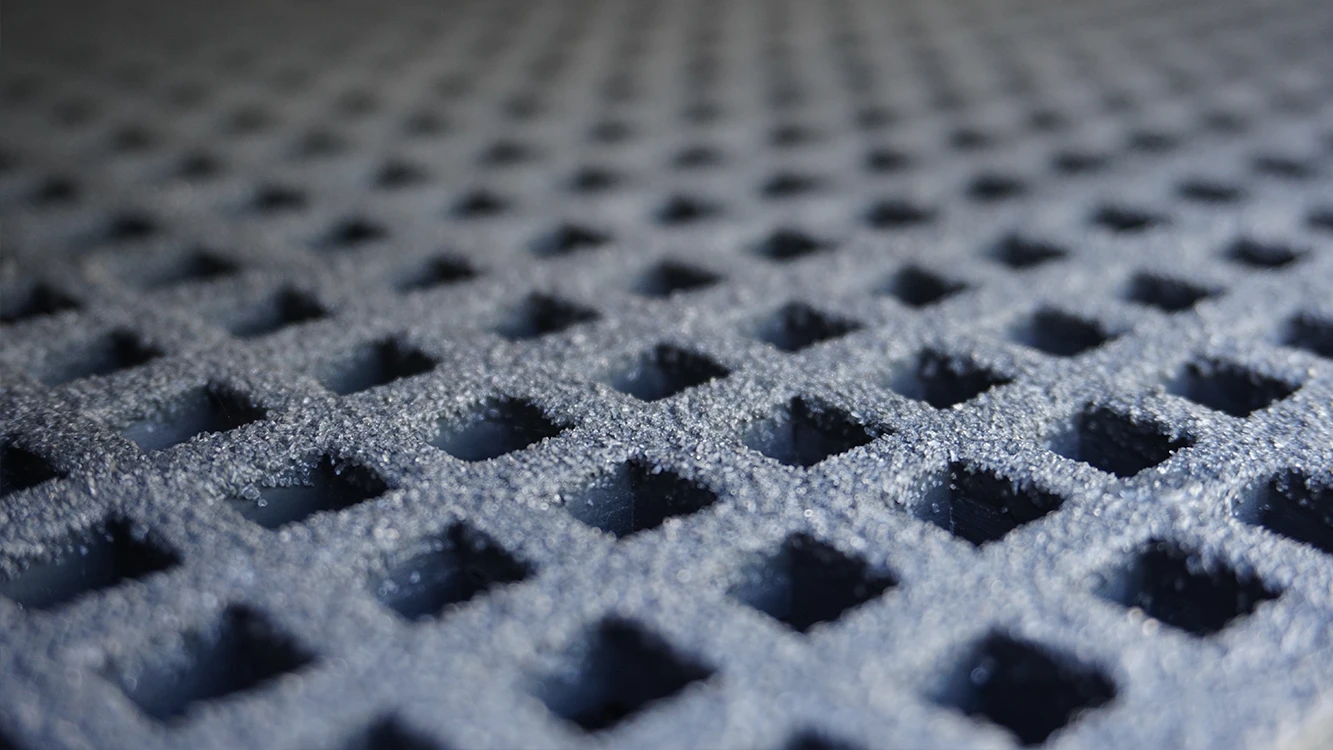

As experts in GRP grating, we’ve been at the forefront of product development for over a quarter of a century and our grating panels have been installed in industrial, marine and civil construction locations all over the globe as a lasting alternative to corrosive steel grating. Moulded GRP grating comes in many thicknesses, panel sizes and hole shapes and sometimes with the holes covered with a thin layer which is known as covered grating or ‘solid top’.

Mini Mesh vs. Micro Mesh

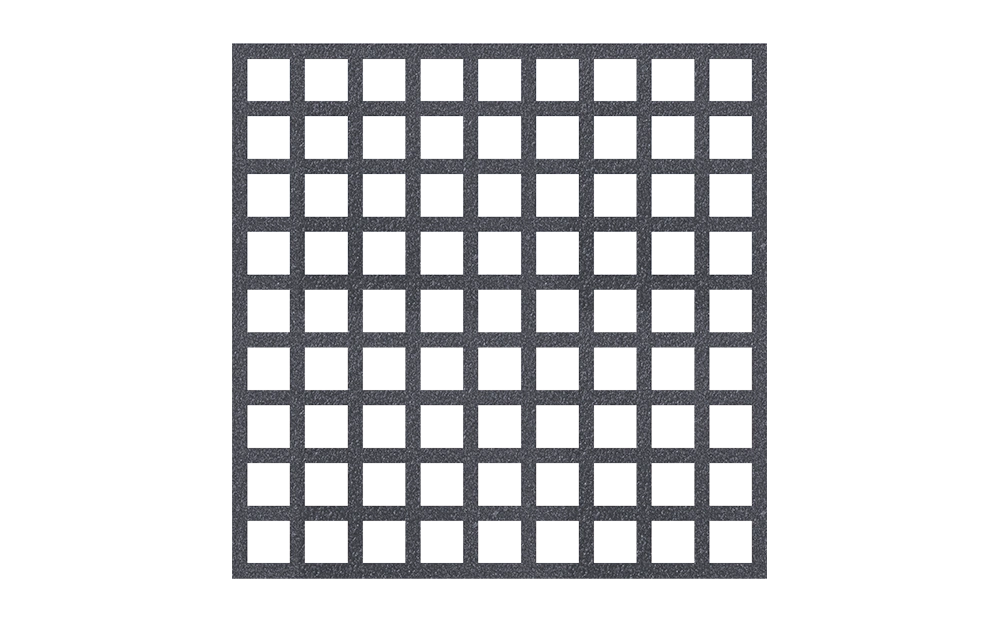

One question we get asked a lot is what’s the difference between mini mesh grating and micro mesh grating. In essence, the basic difference between mini and micro mesh is the size of the holes. Both products have holes smaller than standard mesh grating panels and these holes stop small objects passing through the grating – which is particularly useful if you’re using it as part of a raised walkway or riser void covering.

Dura Composites’ mini mesh and micro mesh grating have a particularly unique and advanced design which makes them more cost-effective than the competition. Both products are part of our next generation d² range of products and offer an impressive performance to weight ratio.

GRP Grating Hole Sizes

Our 23mm Micro Mesh has holes measuring 10.5mm by 10.5mm, making it suitable for all kinds of different footwear as well as for wheeled trollies and other equipment to pass over smoothly. The hole sizes of our 23mm Mini Mesh by contrast measure at 13mm by 13mm. For commercial projects, our thicker 35mm, 45mm and 55mm panels have a hole size of 19.5mm – meaning all products in the range comply with the standard BS EN 14122 Category B and the 20mm European Ball falling test. If you’d like to see both products for yourself, why not order a free sample or a project site visit from one of our technical sales team?