What corrosion-resistant materials are available?

Stainless steel

Stainless steel, especially higher grades such as 316, is one of the most commonly used corrosion-resistant materials due to its durability, strength, and corrosion resistance, especially against chlorides. This is why it is often used in coastal or marine environments.

While it offers excellent protection from seawater, higher performance grades such as 904L, 254 SMO and Alloy 20 may be needed for applications where harmful chemicals are present. Stainless steels are corrosion-resistant because of their passive chromium oxide layer, which protects the surface from oxidation and corrosive attack, but that layer can break down under certain chemical exposures.

Whilst stainless steel is extremely strong, it’s a lot heavier than other choices such as GRP (glass reinforced polymer) which will mean transportation and installation takes longer and costs more for those less accessible applications.

Titanium

Titanium offers excellent corrosion resistance, especially where seawater, acidic solutions, and chlorine exposure are common. It also doesn’t corrode when in contact with many aggressive chemicals and highly reactive substances, making it ideal for desalination plants, power generation condensers and chemical processing.

While titanium offers great strength and is lighter than steel, it is still heavier than GRP. It is also generally considered too expensive for most standard construction applications such as fabrications and access structures, especially compared to aluminum and GRP.

Nickel alloys

Nickel alloys are another material suitable for chemical processing industries due to their ability to withstand harsh environments without degradation. Nickel is needed to make the high-performance alloys used in wind turbines and solar panels, as well as for catalysts for green hydrogen production.

Nickel alloys are lighter than some materials, but are heavier than GRP. Thanks to the global demand for electric car batteries, nickel is in scarce supply, and the industry is often associated with environmental damage.

Aluminium alloys

Aluminium alloys are strong, and lightweight, as well as being non-combustible, making it ideal for applications where fire safety is a priority, such as balconies and terraces.

Aluminium is also fully recyclable, making it a smart, sustainable choice for low-carbon construction.

The protective oxide layer that aluminium naturally forms protects it from a certain degree of corrosion. If exposed to saltwater or acidic conditions for too long however, aluminium and aluminium alloys will usually require protective coatings or anodising.

They are commonly used for electrical transmission structures and solar panel supports.

Galvanised steel

Galvanised steel is widely used in structural, safety and access-related infrastructure in the sector, especially for above-ground, non-immersed applications like handrailing, or for protected or indoor water treatment facilities, where exposure to aggressive substances is limited.

However, harsh chemicals like chloride, sulphides and acids can strip its galvanising layer, leading to rapid corrosion, which is why it’s not usually considered for direct-contact or submerged applications. In these instances, materials like stainless steel or GRP are usually preferred.

GRP (glass reinforced polymer)

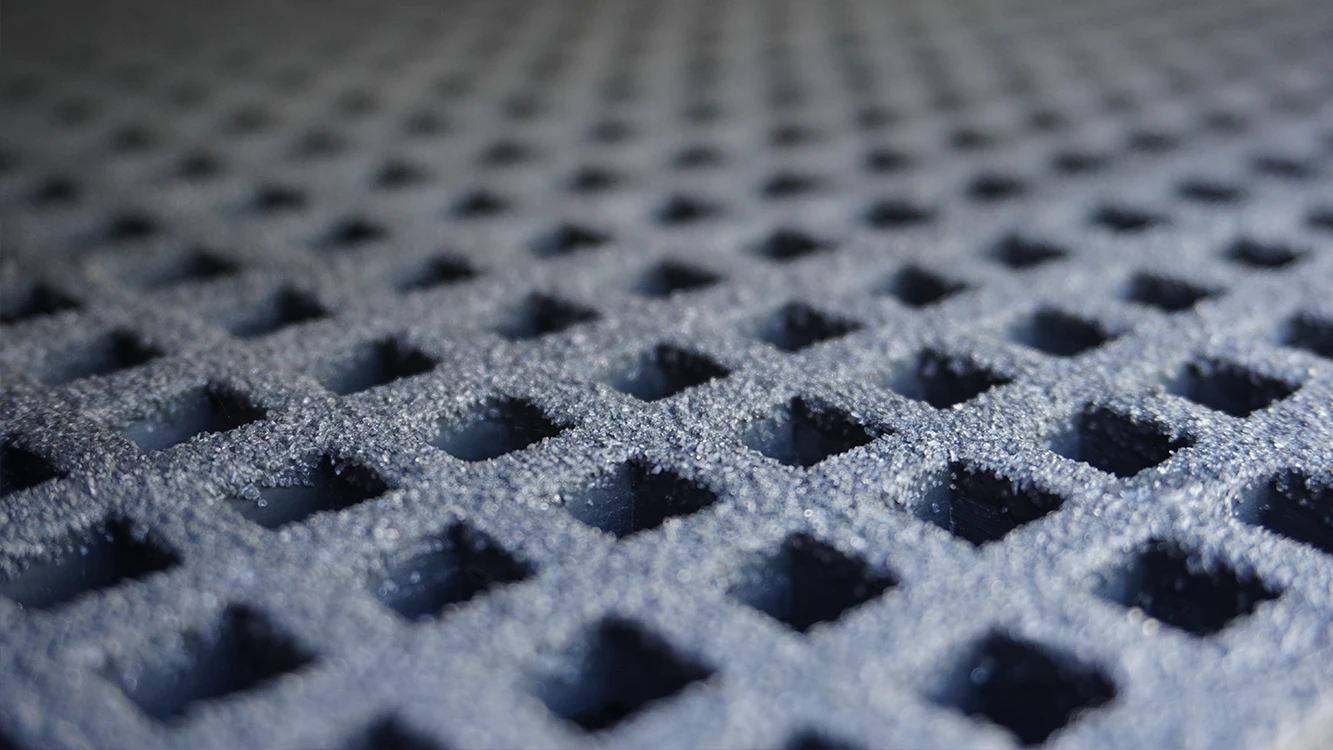

GRP, also sometimes known as fibreglass, is a popular choice for projects in the water and waste, renewable energy, nuclear, and oil and gas sectors. It is particularly useful for offshore installations where the presence of saltwater and atmospheric conditions often leads to severe corrosion in traditional materials. GRP doesn’t rust, corrode or oxidise, nor does it react with acids, bases, or harsh chemicals.

A huge advantage is its strength-to-weight ratio. It is easier (and cheaper) to transport, manoeuvre and install, saving time and labour expense, as well as reducing carbon output. For applications such as trench covers, for example, this makes them a much more attractive alternative.

GRP also requires very minimal maintenance – essential for these difficult to reach applications. It offers a more durable solution than many traditional materials without the need for additional protective measures, such as coatings, that some of the other corrosion-resistant alternatives require.

Because GRP is flexible, as well as being resistant to UV and temperature fluctuations, it can be moulded into complex shapes, and as such, is used for a variety of applications, from fire-rated grating to gantries.

Never one to rest on our laurels, we went a step further and created a new generation of GRP products, known as d². This patented range offers the same outstanding safety, performance and durability, but with up to a third less embodied carbon. This helps companies in the energy and utilities space meet sustainability targets whilst also delivering cost-efficient projects on time.

The environmental and commercial impact of d² products is vast:

- Contractors & Installers benefit from easier, safer, and faster installation, as the lightweight nature of d² reduces labour and lifting equipment requirements.

- End Clients & Public Sector Organisations can demonstrate clear CO₂e savings on projects, supporting net-zero goals and ESG (Environmental, Social, Governance) commitments.

- Infrastructure clients benefit from lower lifecycle costs, thanks to the products’ extended lifespan and corrosion resistance, reducing replacement frequency.

Ensuring you choose the right corrosion-resistant material for your infrastructure project can improve longevity, enhance safety, and reduce maintenance costs. Our experts can help advise you on the right choice for your needs.