LIDAR, which stands for Light Detection and Ranging, is a powerful technology widely used in surveying and mapping applications. It operates by emitting laser pulses and measuring the time it takes for them to bounce back after hitting objects, thereby creating highly accurate 3D representations of terrain and structures.

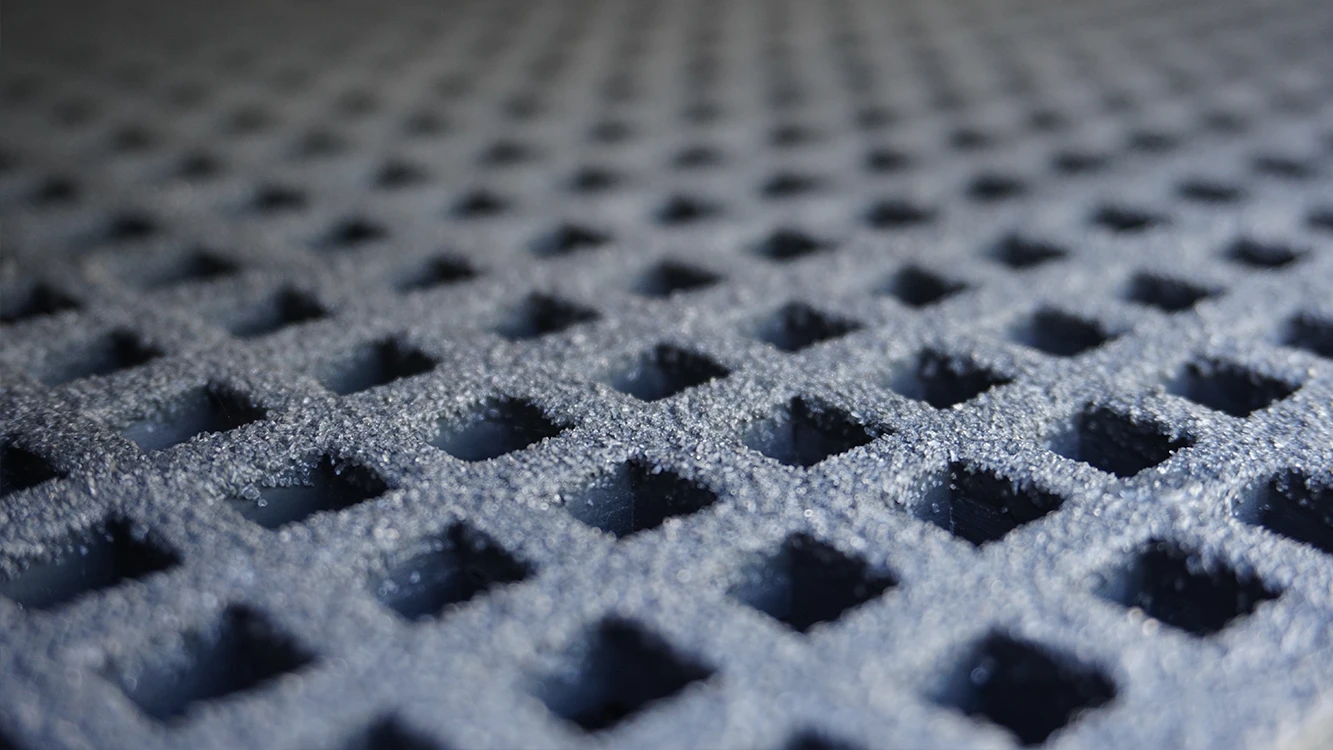

When applied to trench surveying for example, LIDAR provides rapid and precise information about trench depth, width, and shape, that can be used to define the exact requirements for fabricating removable access covers made from composite products such as Dura Slab and Dura Grating. The technology greatly enhances the safety and efficiency of infrastructure projects by minimising the need for physical inspections and reducing human error.

The applications of Dura Composites’ surveying and 3D modelling are extensive, spanning across industries such as civil engineering, defence, and construction. Key benefits include:

- Time Efficiency: Photogrammetry drastically reduces the time required for surveying and data collection compared to traditional methods. Projects that once took weeks or even months can now be completed in a fraction of the time.

- Safety: The ability to access difficult, dangerous, or expensive-to-reach areas without exposing manned surveying teams to risk is a major safety advantage.

- Precision: Measurements derived from point clouds are accurate to within a few centimetres, ensuring that project plans and designs are built on a solid foundation of data.

- Cost-Effective: The efficiency and accuracy of photogrammetry translate into cost savings for clients, as it minimises the need for costly on-site resources and rework.