Negate the need for continual replacements

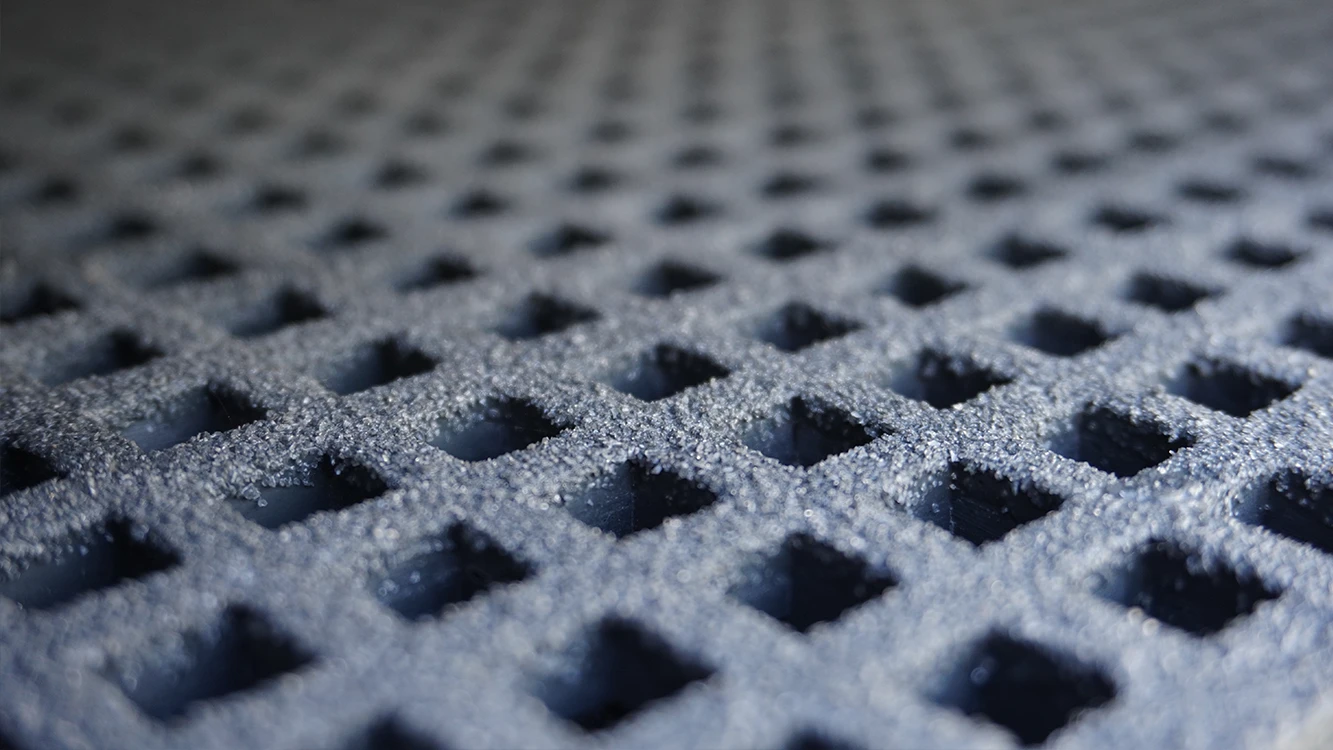

Our closed-cell Glass Reinforced Polymer (GRP) offers water resistance, fire safety, and anti-slip properties, maintaining its strength consistently over its lifecycle. Unlike plywood flooring, which often requires frequent replacement due to issues like refrigeration leaks and spills in stores, GRP products provide a durable solution for retail environments. They negate the need for continual replacements, providing an anti-slip, fire-tested, and load-tested alternative. Additionally, GRP is workable with standard hand power tools and is perfect for demanding retail applications where heavy footfalls are common.

In recent projects for a major Supermarket chain, we supplied the full design and layout for replacement subframes and flooring to provide a durable alternative to the customer’s current solution which was continually failing in 3 year cycles. The design required the Dura Composites solution to achieve a point loading of 3.6kN for a 50×50 patch and a 4KN/m² UDL – to simulate the effects of a trolley load. The allowable deflection was set at 5mm. As well as being able to demonstrate how our products could achieve the above, we were also selected due to the ability to bond the Supermarket’s chosen finished floor tile (either Amtico or Gerflor) to our Dura Grating Solid Top GRP flooring product.

Long-performance flooring with minimal maintenance

Whether installing GRP fresh or replacing an existing material, works can be carried out swiftly with minimal disruption to the day to day running of the business, which is ideal for retail infrastructure projects. As the above example shows, where long-performance flooring with minimal ongoing maintenance is required, our GRP products are the ideal solution. Our advanced composite materials boast a range of benefits, including:

- Lightweight with an incredible strength-to-weight ratio

- Non-corrosive

- Non-conductive

- Low-maintenance lifecycle

- Fire-tested

- Load-tested

- Proven anti-slip

- Water resistant versus ply

Why Plywood is not the long term and most sustainable solution

Plywood has been a common material within the retail sector throughout the years, used for flooring, internal and external walkways and stairways. But as composite materials advance, plywood is no longer the best material for these applications. It is highly susceptible to ingress of water which causes delamination and degradation of the product. The open cell nature of plywood means that water absorption occurs at different rates from panel to panel, making product performance and ultimate failure rates hard to predict. As well as this, whenever holes are drilled into plywood for installation, water is able to penetrate. This becomes a major concern when it’s used below fridges and freezers, as water leakage is common.

There are methods installers often take when working with plywood in order to increase its fire safety, but most of these methods can compromise the integrity of the material over time. For example, phenolic coated ply has a higher standard of fire resistance than traditional plywood, but water leakages can find their way into the core of the ply, resulting in the failure of the material within weeks. Fire retardancy can be added into standard plywood, but this weakens the glue line, in turn weakening the entire plank.

* The 30% figure is calculated from the saving in kilograms of CO2 equivalent of the anticipated replacement cycle of 36mm plywood over a 30 year installation based on just the materials at 11.85 kg CO2e, not even taking into account the additional carbon output from the repeated replacement installation which would result in much higher real-world values.