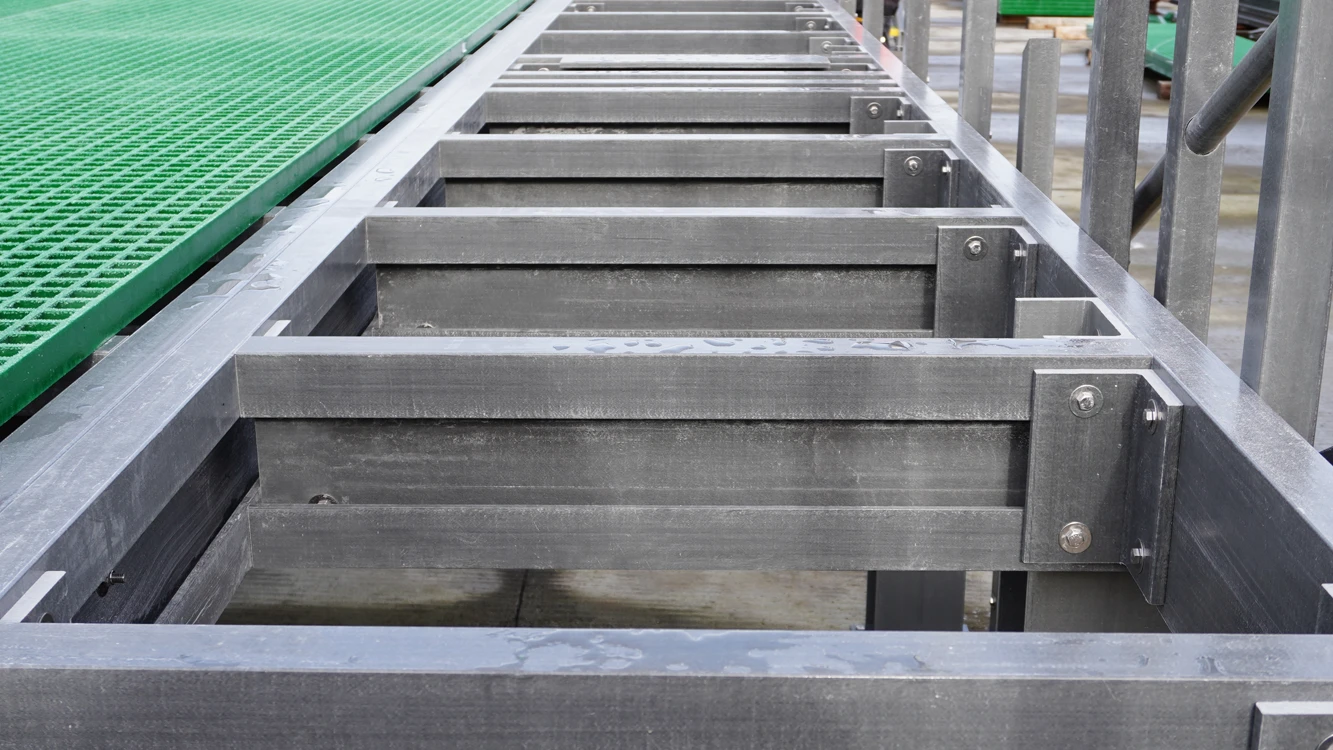

Is it time to replace the wooden bearers in your inland marina for something more durable?

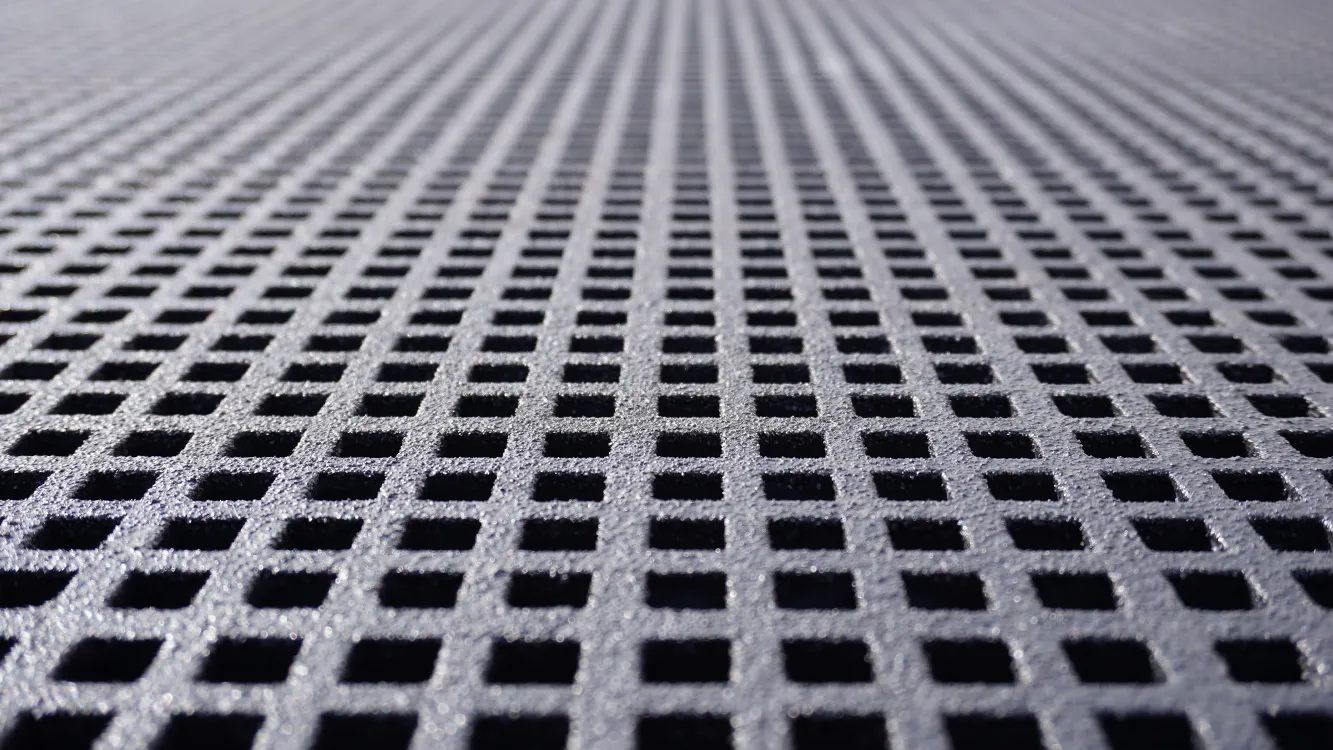

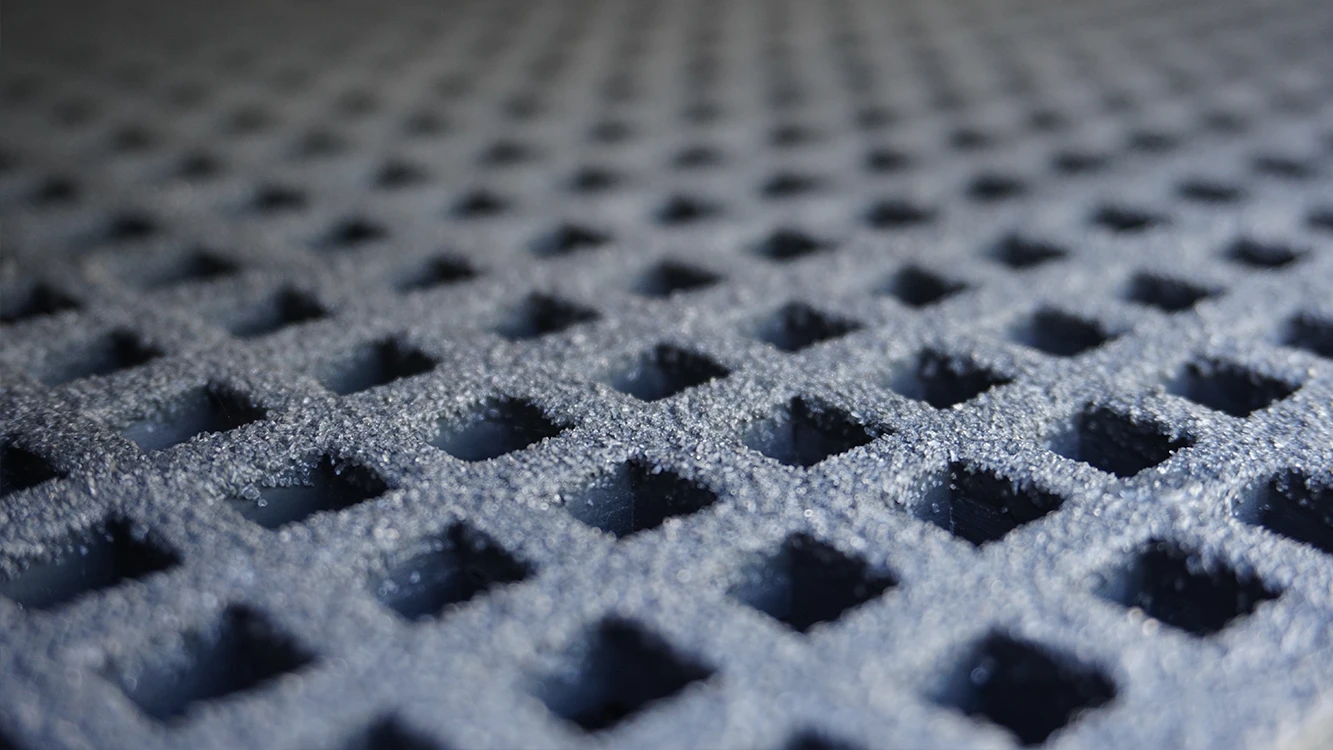

Once a ubiquitous material in construction and structural applications, wood has experienced a decline in popularity in recent years. This shift away from wood as a primary structural material can be attributed to a variety of factors, including the emergence of alternative materials like GRP and aluminium composites, concerns about deforestation and sustainability, as well as changes in regulatory requirements. If you’re using wooden substructures in your marina, here are some factors you might like to consider: