As a construction project progresses from a client’s statement of need, through design and construction and into operation and use, project teams seek increased certainty regarding criteria such a layout, fit, cost and performance.

This means that building services design must be integrated into the overall building design from an early stage, particularly on complex building projects. The detection of clashes between Mechanical and Electrical services and other building components can be a significant cause of delays and variations on site, not just in terms of the physical placement of the services themselves, but also in terms of ensuring safe access to allow the M&E contractor to connect those services.

This is the reason that you’ll often hear our competitors championing how their solutions force M&E design to early completion as they simply aren’t flexible enough to be modified on site as requirements change. But in truth, even the best planned projects are subject to last minute M&E changes, and when it comes to making your riser voids secure, you need a solution that can accommodate these changes on-site without the fear of ballooning cost. With Dura Composites you can get full budget pricing in as little as 48 hours.

The Dura Riser Strategy is simple:

-

Design for all stages of the building lifecycle

Our galvanised steel framework and GRP grating covers offer the perfect combination of strength, safety and adaptability on site. Unlike competitor solutions, there is no need to cut service holes ahead of time or to crane heavy steel framework into position and the system is infinitely adjustable to allow for millimetre by millimetre changes. All components of the Dura Riser system are also suited to manual handling and can be adapted for use with unusual substrates such as hollow or clay pot. Dura’s system is ideally suited to modular construction and enables safety requirements to be more easily met and policed. Not only is there a reduced risk of trips, slips and falls – particularly as work at height is reduced – but there is also a reduction in onsite activity.

-

Reduce the risk wherever possible

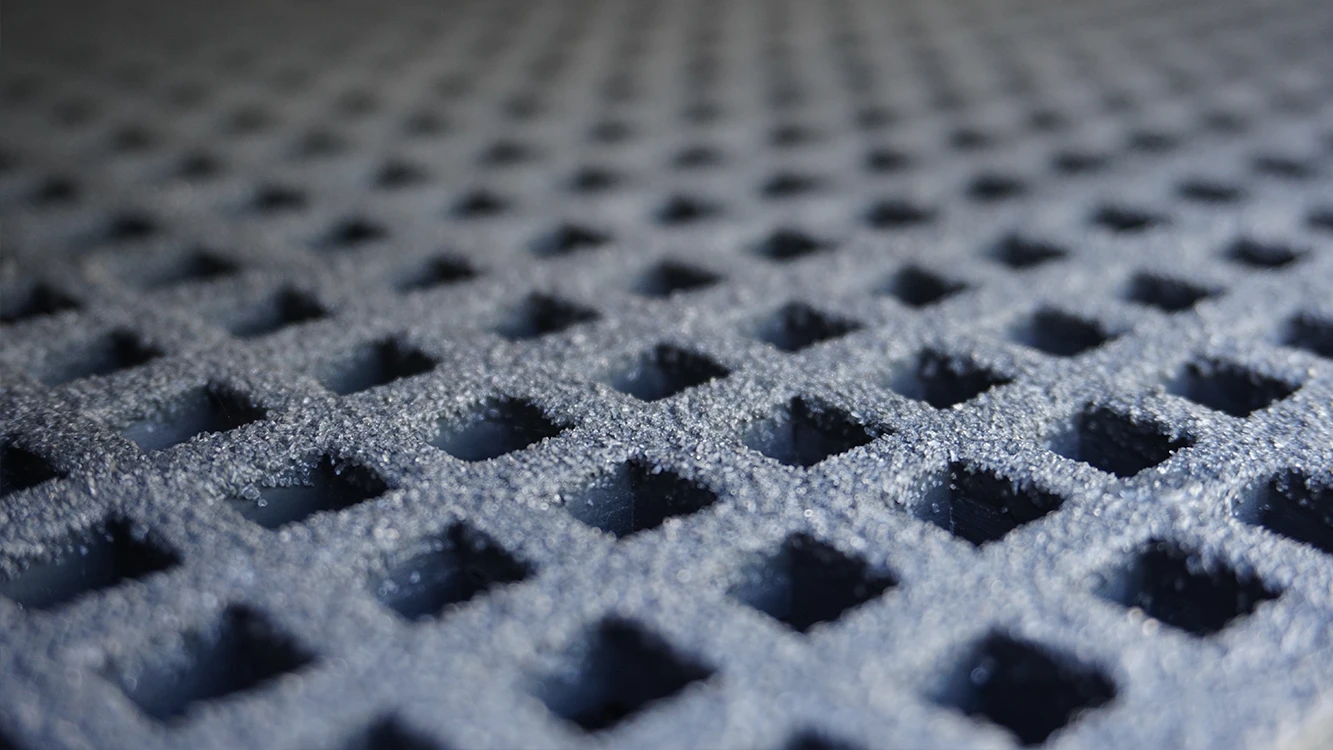

Whilst no standard exists specifically for riser void protection, our Dura Riser system is designed to comply with the rigorous standards set out in BS 4592-0:2006 + A1:2012. Service cut outs can be made “just in time” to minimise the risk for on-site personnel, and our mini mesh gratings complies with the European Ball Falling test requirements. Dura Riser Grating features our best ever gritted surface which is tested to over 1 million footfalls (in accordance with BS 7976-2:2002+A1:2013) and outperforms all other products in the market when it comes to durability and anti-slip properties.

-

Keep it simple

Our standard Dura Riser steel framework comprises of four innovative patent pending components that can be used in a wide range of scenarios for risers with a span of up to 3 metres. We offer both a supply-only and a fully installed solution. Where service penetrations are required, additional supports may be needed, and our experienced team can also create and install bespoke solutions for complex riser voids. No hot works permits are required for cutting service holes on site, thanks to the non-conductive and non-sparking properties of the Dura Riser grating.

-

Safer at the point of need – for less money

Dura’s Riser solutions are a safer option than corrugated plastic, plywood and netting and prove more cost effective in the long run as they offer much needed flexibility to construction teams. There’s no need to remove and replace heavy cover plates, and no significant contribution to construction waste. Using Dura Riser 41mm Solid Top grating eliminates the need for additional coverings such a corrugated plastic, netting or plywood, saving even more cost.