Ideal for electrified environments.

The Beatrice Offshore Wind Farm is a wind farm close to the Beatrice oil field in the Moray Firth, 13 km off the north east coast of Scotland. Scotland’s single largest source of renewable energy, this £2.65bn project involves 84 Siemens Gamesa turbines and achieves 588MW of electricity.

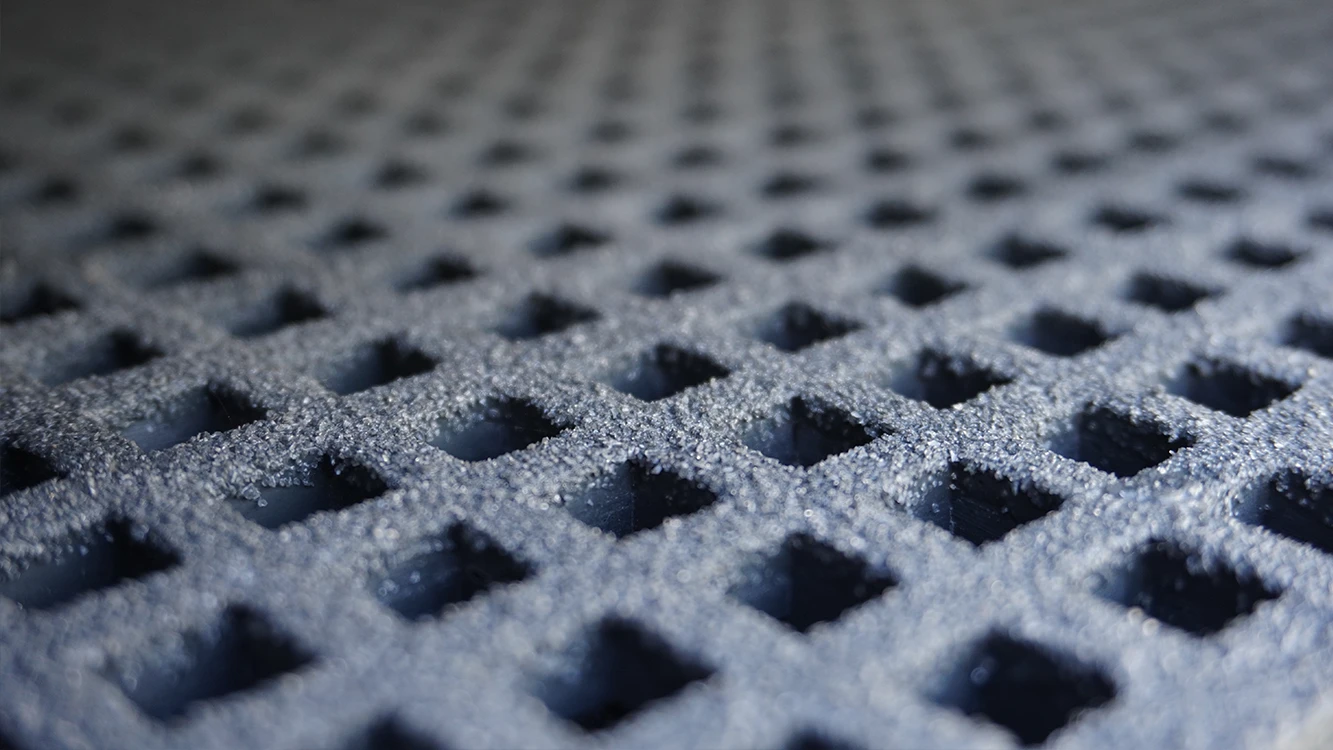

Non-conductive solutions that meet specific load classes.

Dura Composites specialises in the supply of high quality non-conductive Glass Reinforced Polymer (GRP) grating, handrail and slab products which are ideal for use in electrified environments across the energy and utilities industries. Our clients, RJ McLeod and Siemens Wind Power and Renewables Division were looking for a material for the Beatrice project which was non-conductive, met specific load classes, was easy to install, corrosion-resistant, slip-resistant, and that could comply with the existing colour scheme currently employed for similar projects.

Dura Composites extensive GRP product range meant that we could provide live load tested solutions for a vast range of applications across the site. Our flooring products feature UV inhibitors which protect against sun degradation and the innovative anti-slip surface is tested to an incredible 1.1 million footfalls in accordance with BS 7976-2:2002+A1:2013.