Designed to accommodate multiple vehicles at once.

Throughout the UK winter, fleets of gritters are on permanent stand-by to undertake precautionary salting at a moment’s notice to keep Britain moving. Dura Composites high-performance GRP Access Structures are playing a crucial role in keeping these vehicles operational and well-maintained. Recently supplied projects include a range of gritter lorry washdown gantries which have been designed to accommodate multiple vehicles at once so they can be easily cleaned, refilled and maintained between winter journeys.

Whilst modern day gritting procedures use a combination of rock salt or white marine salt and an anti-caking agent, the chloride released still has a corrosive impact on steel, aluminium and concrete which can lead to slippery and unsafe walking surfaces and equipment access areas. By contrast, the non-metallic Glass Reinforced Polymer material which Dura Composites structures are fabricated from is resistant to a wide range of chemicals and has an expected design life in excess of 60 years. Durable and low-maintenance, it is also up to 80% lighter than steel, making it more cost-effective to transport and install.

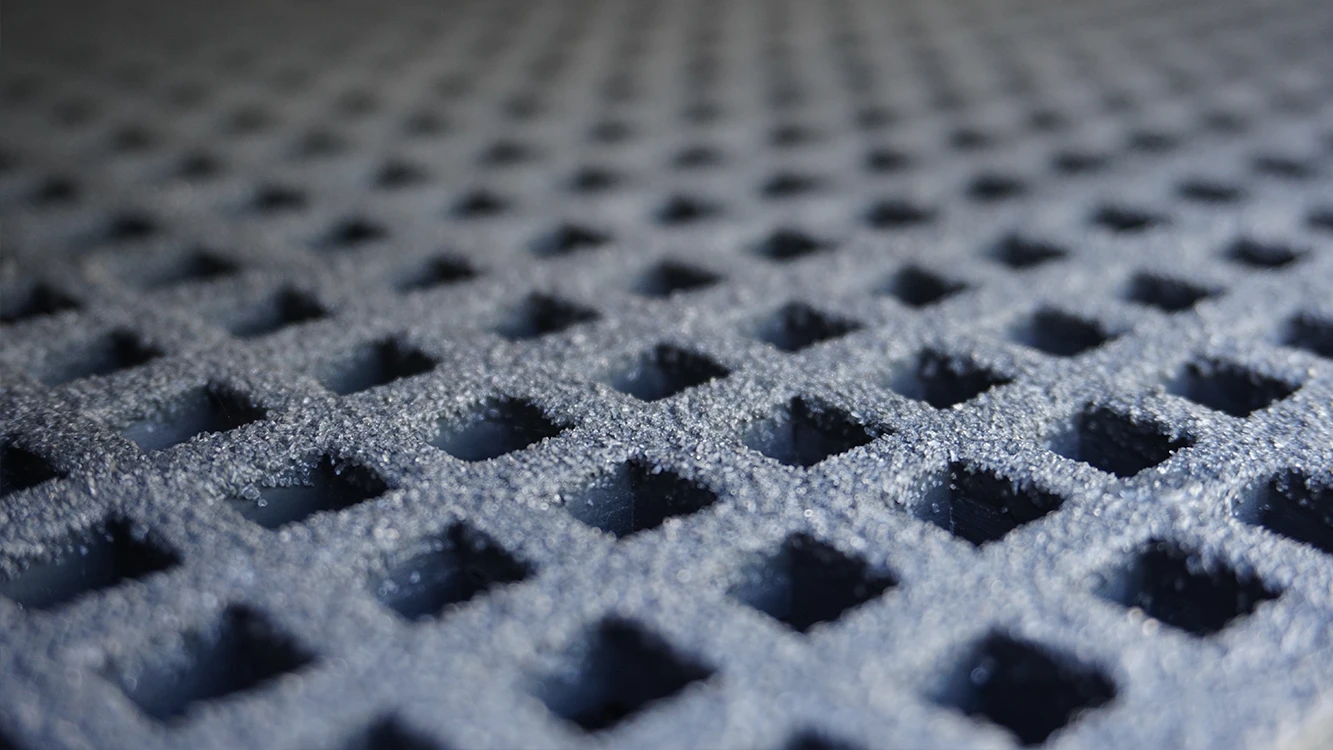

Cost-effective, practical and safe, Dura Composites fabrications are constructed from our market leading d² E23 Grade Dura Profile sections and open mesh anti-slip Dura Grating panels. In this project, a bespoke design was created by our in-house CAD team, meaning that each structure could accommodate several vehicles at once, enhancing operational efficiency and improving worker safety.