Early engagement. Lower risk. Better outcomes.

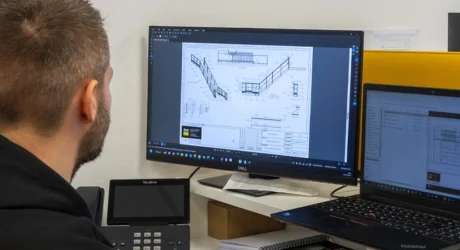

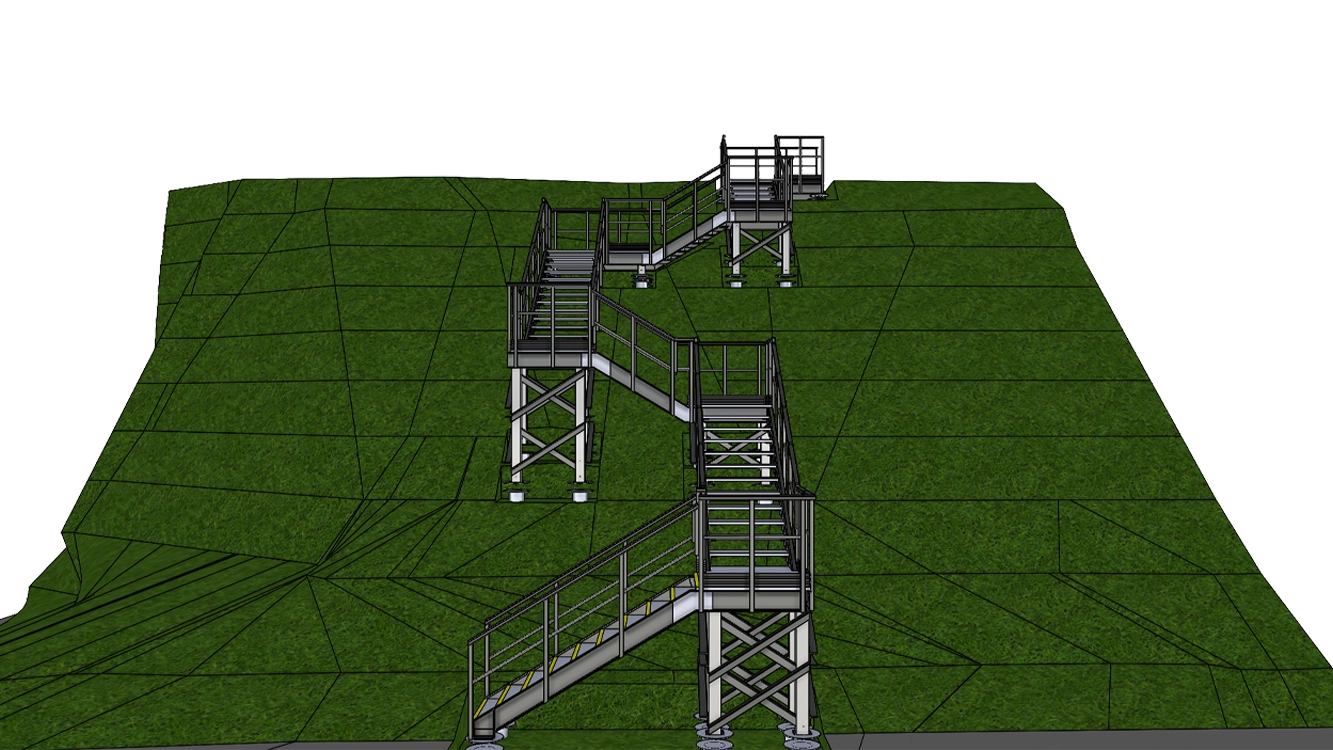

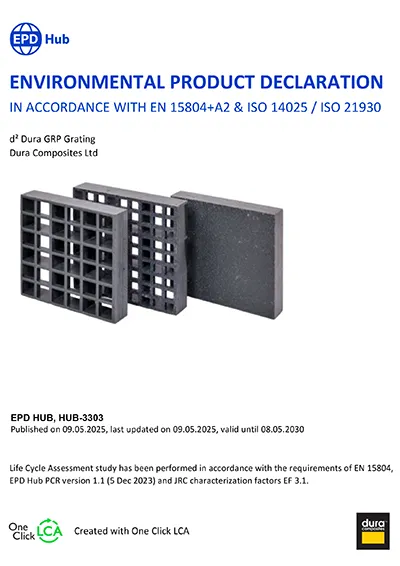

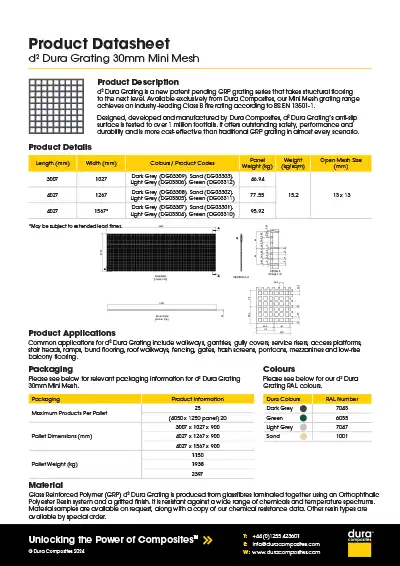

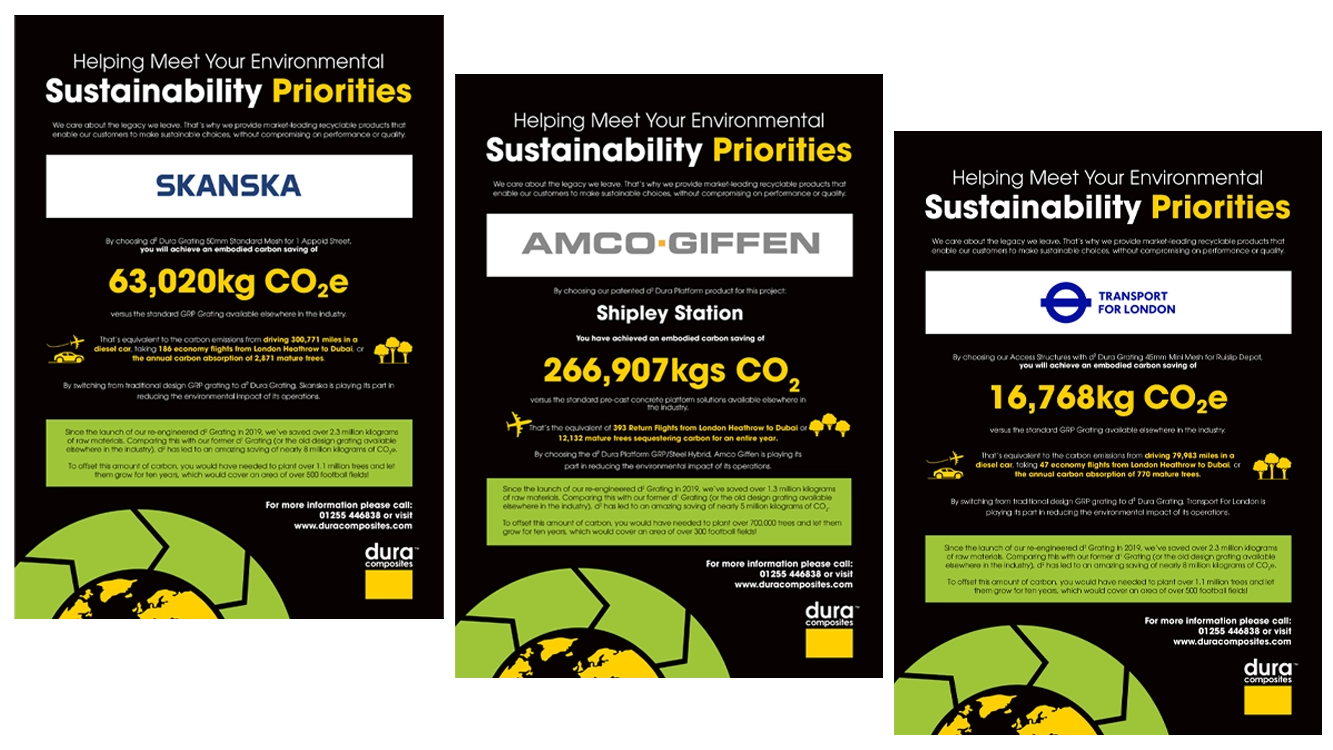

We work alongside you early in the design process, where the biggest decisions — and the biggest risks — are shaped. Our role is to support your design intent, reduce uncertainty and help you lock in solutions that stand up technically, commercially and environmentally. We provide engineering insight, verified data and practical guidance that help you make confident, defensible decisions from concept through to delivery.

Early engagement also helps you to maintain design integrity and avoid late-stage disruption by enabling effective clash detection while the design is still at concept stage, helping identify and resolve interface issues before they translate into programme risk or site-based compromise.