Scope of Works

- Fabrication and delivery of bespoke GRP Driver Access Platforms (DAPs)

- Supply and integration of GRP handrailing and access gates

Driver Access Platforms (DAPs)

Engineered GRP platforms provided safe and reliable access for driver changeovers, inspections and stabling operations. Fabricated at Dura’s ISO-9001 certified facility, the DAPs were transported to site fully assembled for rapid installation during limited possession windows.

At up to 65% lighter than steel, d² GRP solutions enabled faster installation with reduced need for heavy plant. Fully recyclable at end of life, the products deliver significant embodied carbon savings in line with TfL’s sustainability targets.

Tailored for Safety, Sustainability and Speed

South Harrow Sidings presented a series of delivery challenges, including constrained access, live track interfaces, and the need to maintain operational readiness. Dura Composites’ GRP systems provided clear advantages:

Non-conductive, ideal for electrified environments

- Pre-fabricated for rapid installation during short possession windows

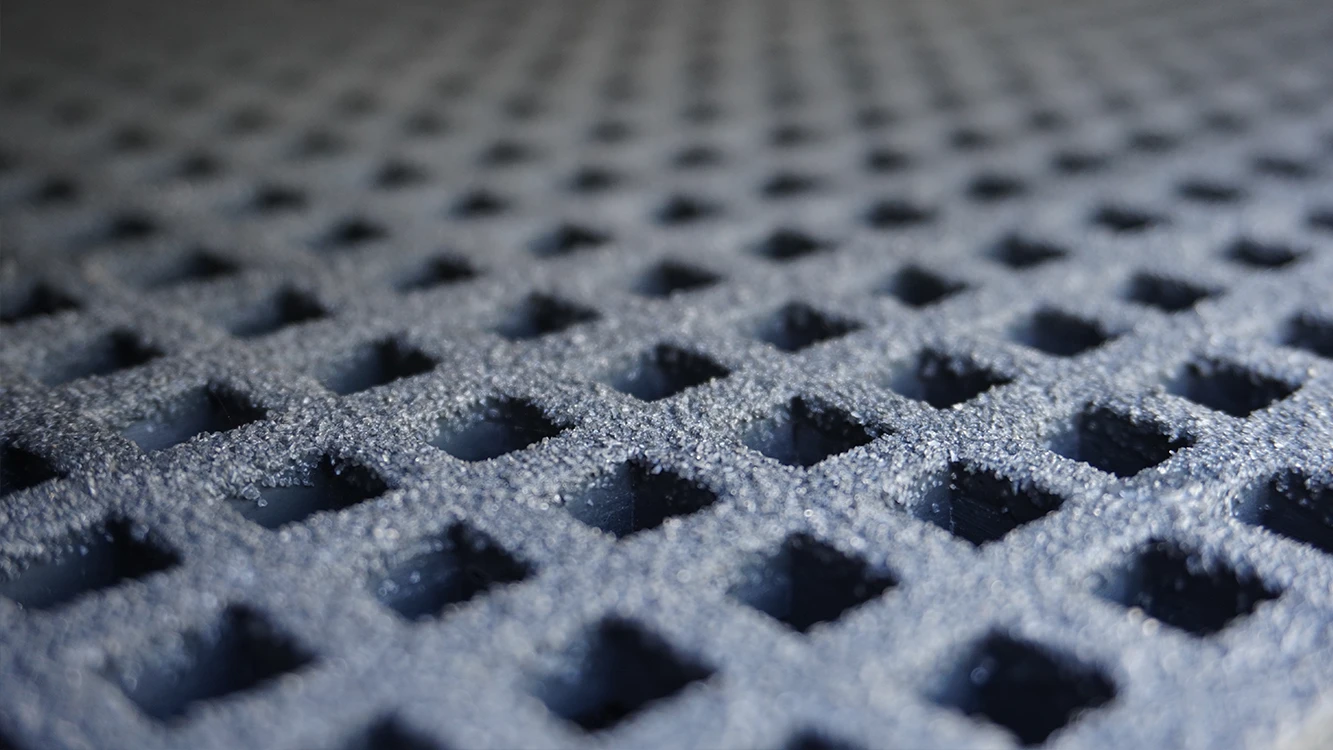

- Anti-slip surfaces tested to over 1 million footfalls, delivering ultra-low slip risk

- Fully recyclable and corrosion-resistant, reducing whole-life costs

- Contributing to Greener Rail Infrastructure

By replacing traditional metallic materials with d² GRP systems, TfL achieved a durable, low-maintenance and lower-carbon upgrade for South Harrow Sidings. The project is a key milestone in the delivery of the Piccadilly Line Upgrade, enabling the new tube fleet and supporting decarbonisation objectives across London Underground’s network.