Tailored Design for a Complex Environment

Each subterranean chamber presented unique challenges, with critical pipework and plant dictating the geometry of the new access solutions. To overcome these, Dura Composites carried out a 3D laser scan of all chambers, capturing millimetre-accurate data.

Using this digital survey, our engineering team designed bespoke GRP staircases, platforms and handrailing that could be installed around existing live infrastructure. All components were fabricated offsite, then delivered in kit form to allow safe installation through narrow hatches where a traditional stick-build approach would have been impossible.

All structural elements were designed to 5kN/m² L/200 deflection, ensuring compliance with MAS Standards and providing a robust, long-term solution.

Scope of Works

- 3D scan of all pump room chambers

- Design and supply of bespoke GRP walkways, staircases and inspection platforms (MAS and WIMES compliant) to replace temporary scaffolding

- Installation of GRP handrailing for fall protection at leading edges

- Fabrication of custom GRP void covers for hatches, supporting safe maintenance access

- Offsite fabrication, delivery, and technical support for accurate kit reassembly

Driving Long-Term Durability and Safety

Dura Composites’ d² GRP access structures provided Anglian Water with a permanent solution built for longevity in a corrosive, H₂S-rich environment. Key benefits included:

- Faster, safer installation with reduced confined space working

- Long-term resilience against corrosion, moisture and decay

- Reduced lifecycle costs compared to steel or scaffolding alternatives

- 25-year insured warranty and 60-year design life (vs competitor standard 12 months warranty, 25-year life expectancy)

- Embodied carbon savings, validated in a Carbon Saving Statement

- Fully recyclable at end of life, supporting circular economy goals

- Zero on-site fabrication required thanks to precision 3D scanning

Sustainability – Lowest Carbon Walkways in the World

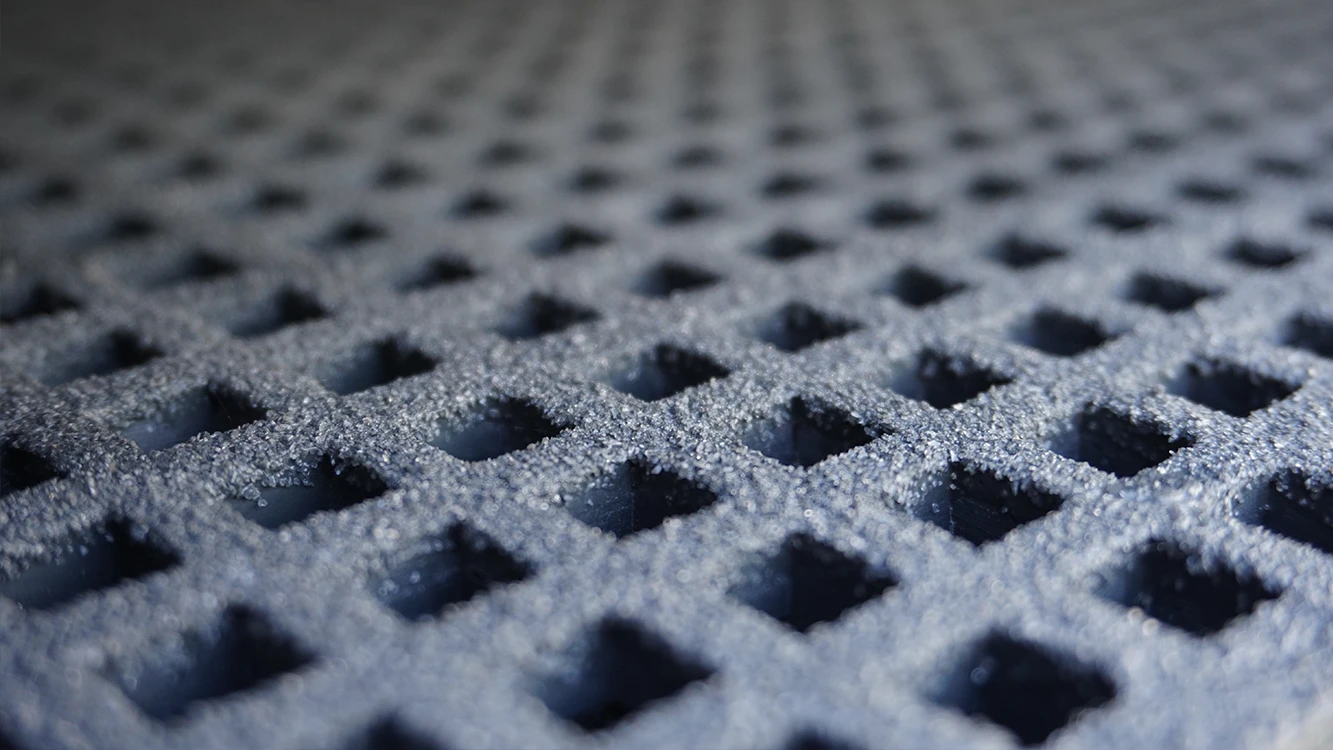

By selecting our patented d² Dura Grating range, Anglian Water achieved an embodied carbon saving of 1,421 kg CO₂ compared to standard GRP grating products available elsewhere in the industry. To put this into perspective, that’s the equivalent of 4 flights from London Heathrow to Dubai or the carbon captured by 65 mature trees over the course of a year.

Alongside these measurable environmental benefits, d² GRP also reduces long-term maintenance requirements thanks to its corrosion resistance and durability. As a cost-effective alternative to 316/A4 stainless steel, it provides equivalent performance at a fraction of the cost — without the risk of rust or decay.

By switching from traditional GRP to d² Dura Grating, Anglian Water is actively reducing the environmental impact of its operations while securing a safe, compliant, and future-proofed access solution.

View the carbon saving certificate