Driving down carbon and maximising existing potential.

20 Giltspur Street is a blueprint for how modern construction can retain and repurpose existing assets while achieving best-in-class sustainability outcomes. Reusing the majority of the steel frame not only preserved the character and footprint of the original building, but also saved thousands of tonnes of carbon compared to new build alternatives.

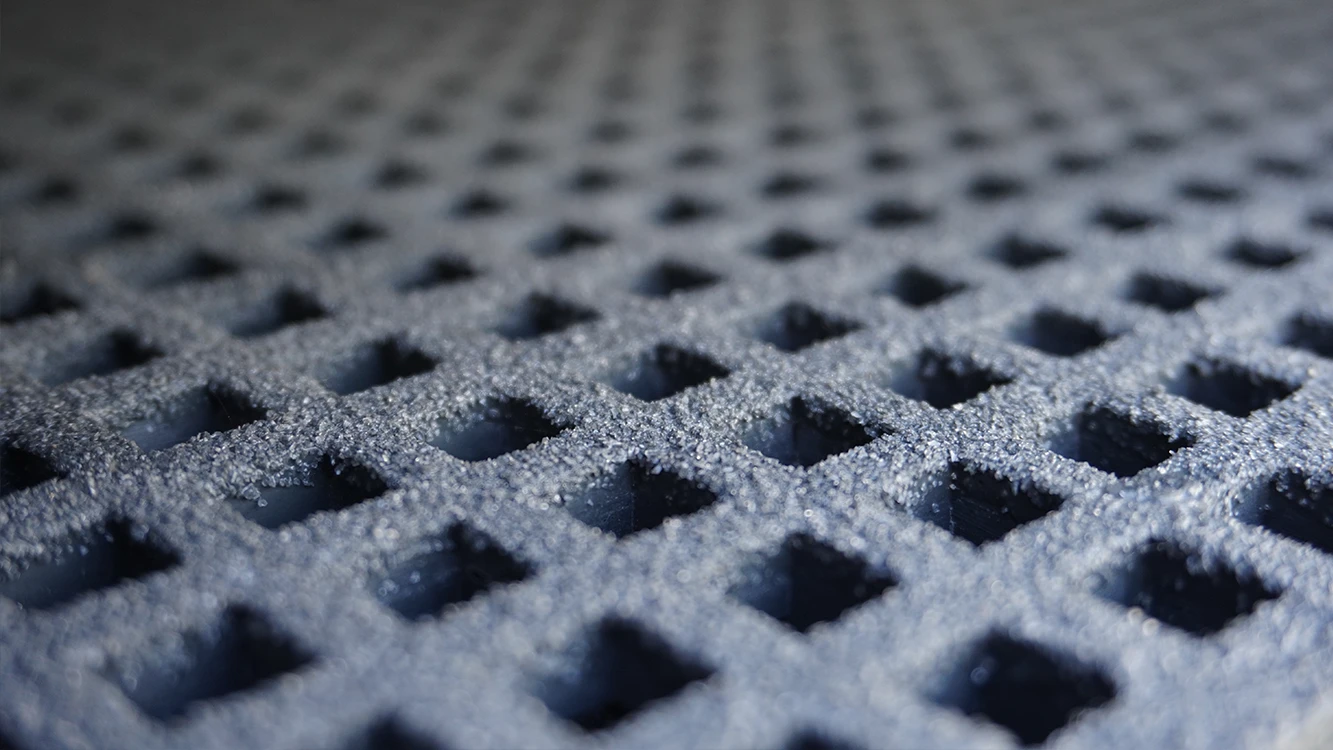

Aligned with this carbon-conscious approach, Dura’s d² Dura Riser system – the lowest carbon riser flooring solution available on the market – saved an additional 10,715 kg of embodied CO₂. That’s the equivalent of 32 return flights from London to Dubai, or the annual carbon absorption of 487 mature trees.

An unexpected highlight of the works was the preserved section of a Roman Londinium wall in the lower basement area – an important archaeological feature which will be conserved and sensitively integrated into the final building design as a tribute to the site’s rich historical legacy.

Dura Composites contributed to this landmark achievement with the supply and installation of our patented d² Dura Riser system, providing fall protection across 82 separate riser voids throughout the building, including an exceptionally large 7 metre by 2 metre riser adjacent to the newly repositioned lift shafts on the first floor.

Lightweight yet robust, the d² Dura Riser system offers exceptional strength-to-weight performance and is fully recyclable – including the panels, supporting steelwork, and fixings packaging. Designed with M&E integration in mind, service penetrations can be made on site without the need for hot works, helping to accelerate programme delivery and coordinate seamlessly with other trades.

All works were delivered by Dura’s specialist Operations Services team, who are fully IPAF and PASMA trained and experienced in managing complex access and sequencing challenges on city-centre developments.