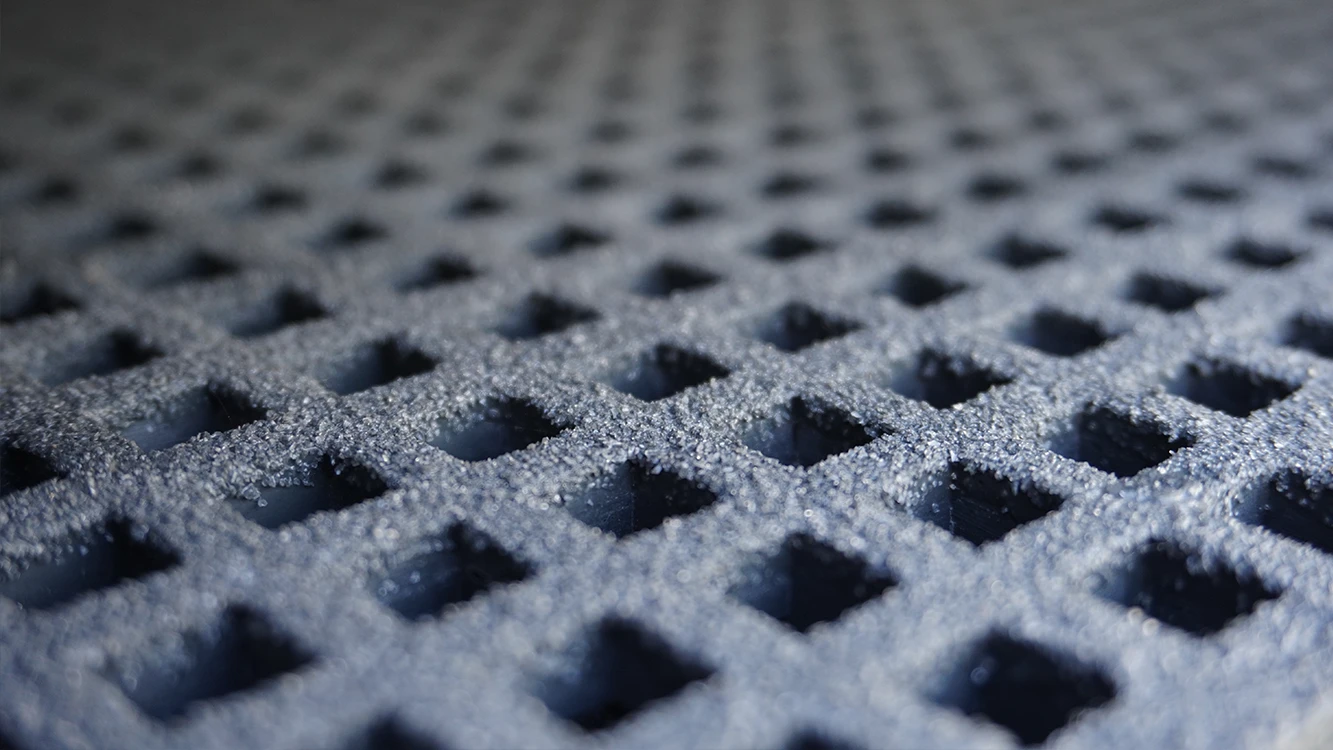

d² is the next generation of GRP

Many people are now familiar with the advantages of using composites over traditional materials, but not all composites are created equal.

Dura’s tried and tested patent-pending d² technology GRP grating is manufactured for maximum performance and is safer, stronger and lighter than other GRP grating products, as well as achieving an industry-leading Class B fire rating according to BS EN 13501-1*.

Our market-leading d² product range includes station platforms, trackside walkway grating, trench covers, structural profiles, handrailing, fencing, end of platform gates and access structures. Their weight-reducing designs minimise on-site logistics, saving time and money.

The innovative design of our d² range, using only the finest quality raw materials, and cutting-edge manufacturing, means our GRP products all save at least 33% embodied carbon. They’re also fully recyclable at the end of their lifecycle, helping the UK meet its 2050 net zero target.

Read more about d² GRP grating here.

*excludes 23mm mini and micro mesh variants