Accelerate project delivery with our professional installation service.

We offer installation. Our dedicated installation team ensures your project runs smoothly, safely, and on time. With the qualifications, experience, and professionalism needed to deliver a hassle-free experience, we operate across all sectors — from high-rise residential and commercial developments to industrial and civil infrastructure works.

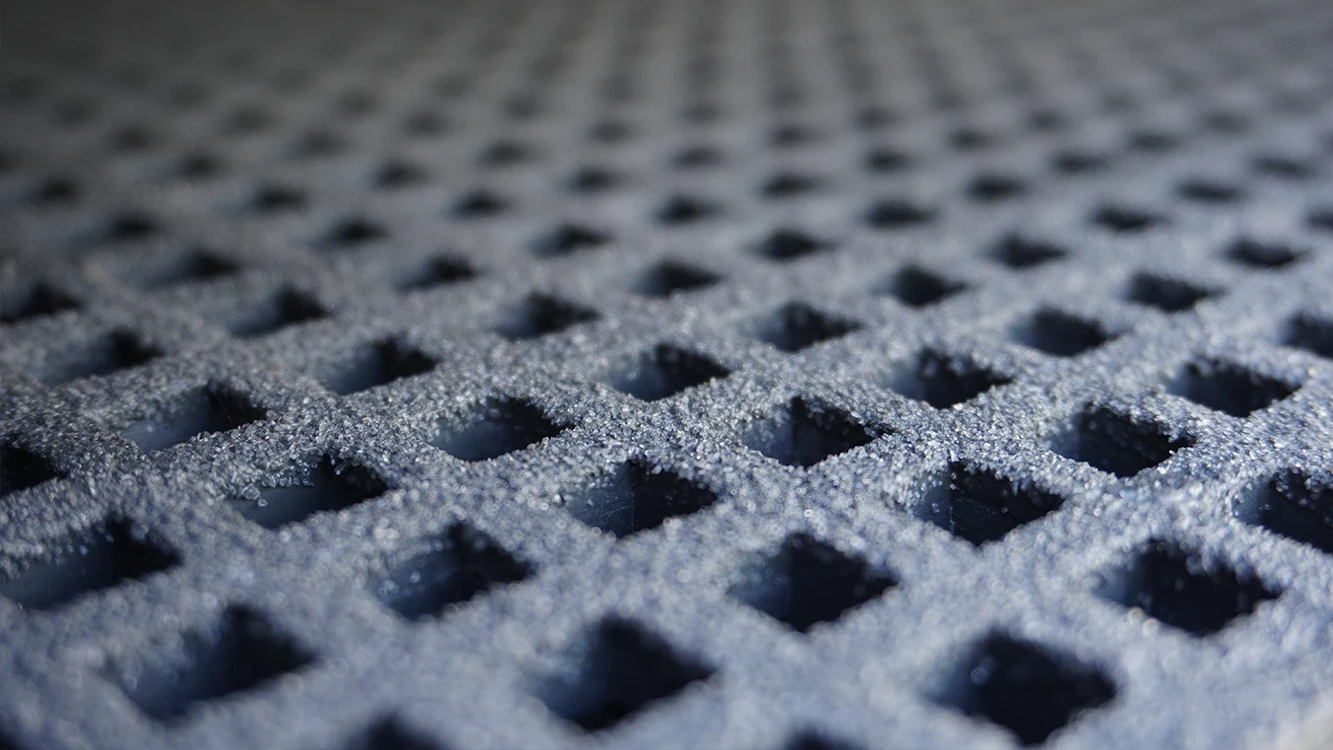

Our Operations Service team includes IPAF and PASMA qualified operatives, and our Site Managers consistently receive outstanding feedback for their attention to detail. Whether it’s riser void coverings, balcony decking, or complex Glass Reinforced Polymer (GRP) fabrications, walkways and access structures, we provide installation support tailored to your specific needs.

For high-rise new builds and refurbishments, we offer a full turnkey solution for our riser void fall protection systems. Our team ensures your mechanical and electrical (M&E) interfaces are considered from the outset — asking the right questions early, such as whether risers will be formed before or after installation, whether materials should be pre-cut or drilled off-site, and when your service cut-outs will be required.

For existing balconies and terraces affected by the ban on combustible materials, we help you achieve compliance with current regulations using our in-house specialists to install Dura Deck Inspire porcelain or Dura Deck Aluminium decking.

If you’ve commissioned a GRP access structure from us, we can take care of the installation too. The cost depends on location and project complexity, but our expert team is ready to advise and support civil infrastructure works, every step of the way.

No matter the sector or scale, our installation service brings certainty, quality, and efficiency to your project.