Vacancy

Senior Fabricator

Are you passionate about precision engineering and eager to contribute to the creation of bespoke structures? If so, we have an exciting opportunity for you to join our team as a Senior Fabricator! In this hands-on role, you will assist with cutting materials and assembling custom structures, ensuring accuracy by following specifications, company processes, and cut programs.

You’ll work closely with CAD and SolidWorks drawings to bring designs to life, maintaining high-quality standards throughout the fabrication process. Your attention to detail will also be key in capturing and managing photos of completed jobs, supporting quality control, and overseeing stock take rotation activities.

If you take pride in maintaining a safe and organised workspace, upholding health and safety standards, and carrying out essential site maintenance, this role is perfect for you. If you’re ready to develop your skills in a dynamic environment and be part of a dedicated team, apply now and take the next step in your fabrication career!

Job Purpose: As a Senior Fabricator, your role is to support the smooth and efficient running of the Fabrication Department by acting as a key point of support on the shop floor. You will lead by example, uphold SmartFab’s visual standards, ensure quality and safety are prioritised, and assist with organising daily workflow. While not in a formal supervisory role, you will help guide and support team members, contribute to training, and play an active part in driving continuous improvement within the department.

Key Duties

Material Cutting & Assembly

- Assist in cutting materials and assembling bespoke structures according to specifications and company processes.

- Work with cut programs, CAD, and Solid Works drawings to ensure accurate and precise fabrication.

- Contribute to achieving departmental goals by utilising the correct tools and equipment for fabricating structures.

- Work collaboratively with team members to ensure efficient workflow and meet production targets.

Photo Management and Quality Control

- Take photos of completed jobs and upload them to the correct location on Salesforce.

- Follow photo management and quality control labelling processes, including completing dimension checks, and obtaining signoffs.

- Collaborate in maintaining accurate stock records and participating in inventory counts.

Safety, Health & Environment (S.H.E)

- Ensure strict adherence to all health and safety requirements, including always wearing appropriate personal protective equipment (PPE).

- Identify and report any safety hazards or concerns to relevant personnel.

Housekeeping & Equipment Maintenance

- Assist in maintaining all equipment in accordance with machine requirements, including regular inspections and cleaning.

- Carry out daily housekeeping duties and assigned site maintenance tasks as directed by the Line Manager.

- Contribute to maintaining a clean and organised work environment.

Knowledge, Skills & Competencies

- Good communication skills and professionalism to effectively liaise with all stakeholders.

- Good knowledge in fabrication, working with cutting materials and assembling structures.

- Ability to contribute to solutions and proposals for problem-solving.

- Familiarity with cut programs, CAD, and Solid Works drawings.

- Basic understanding of quality control processes and photo management.

- Knowledge of stock rotation procedures and inventory management (ISO9001 compliance is a plus).

- Ability to use appropriate tools and equipment for fabricating structures.

- Strong commitment to following health and safety regulations and wearing PPE.

- Basic understanding of equipment maintenance requirements.

- Good attention to detail and ability to carry out tasks accurately.

- Good organisational skills to manage daily duties and contribute to a clean work environment.

- Team player mentality with the ability to collaborate effectively.

Person Specification

- Positively supports company culture and PRIDE values.

- Honest, trustworthy, reliable, and flexible attitude.

- Calm, comfortable in a fast-changing environment.

- High professional standards, strong work ethic.

- Hands-on determination and persistence to get the job done.

- Clear understanding of company and departmental vision.

- Actively contributes to LEAN principles and continuous improvement.

- Strives for World Class standards in quality, efficiency, and safety.

Contract

Permanent

Hours

Monday – Friday

08:30 – 17:00 (37.5 hrs per week)

Location

Dura House, Clacton-on-Sea

Basic Salary

£27,000 – £30,500 (depending on experience) per annum

NPGSBS

Potential to earn 10% of Basic salary, following one year’s service as part of the companywide Net Profit Gain Share Bonus System (NPGSBS)

Total Package

£29,700 – £33,550

Holidays

28 days per year (inc. bank holidays)

(Option to purchase 5 additional days per year)

More Great Reasons to Join Dura Composites

- Full Sick Pay scheme, following 1yr service.

- Auto Enrolment Pension scheme provided by People’s Pension.

- Occupational Health Screening Services.

- BUPA GP appointment services.

- Wellbeing initiatives (e.g. massages, wellness & fitness groups).

- Salary Sacrifice Schemes (e.g. Electric Car Scheme, Tech Scheme).

- Quarterly 1-2-1 welfare & performance reviews.

- Role-specific training & development opportunities, team building activities.

- Choice to attend PRIDE Experience outings, social events, and celebrations across the year.

- Free refreshments, treats, and Friday Lunch Club.

Apply below

Upload your CV and Cover Letter and we’ll be in touch

Company Information

Founded in 1996, Dura Composites offers an unparalleled range of composite solutions that harness cutting-edge design and manufacturing techniques to replace traditional materials such as wood, concrete, and steel across a wide variety of applications and industries.

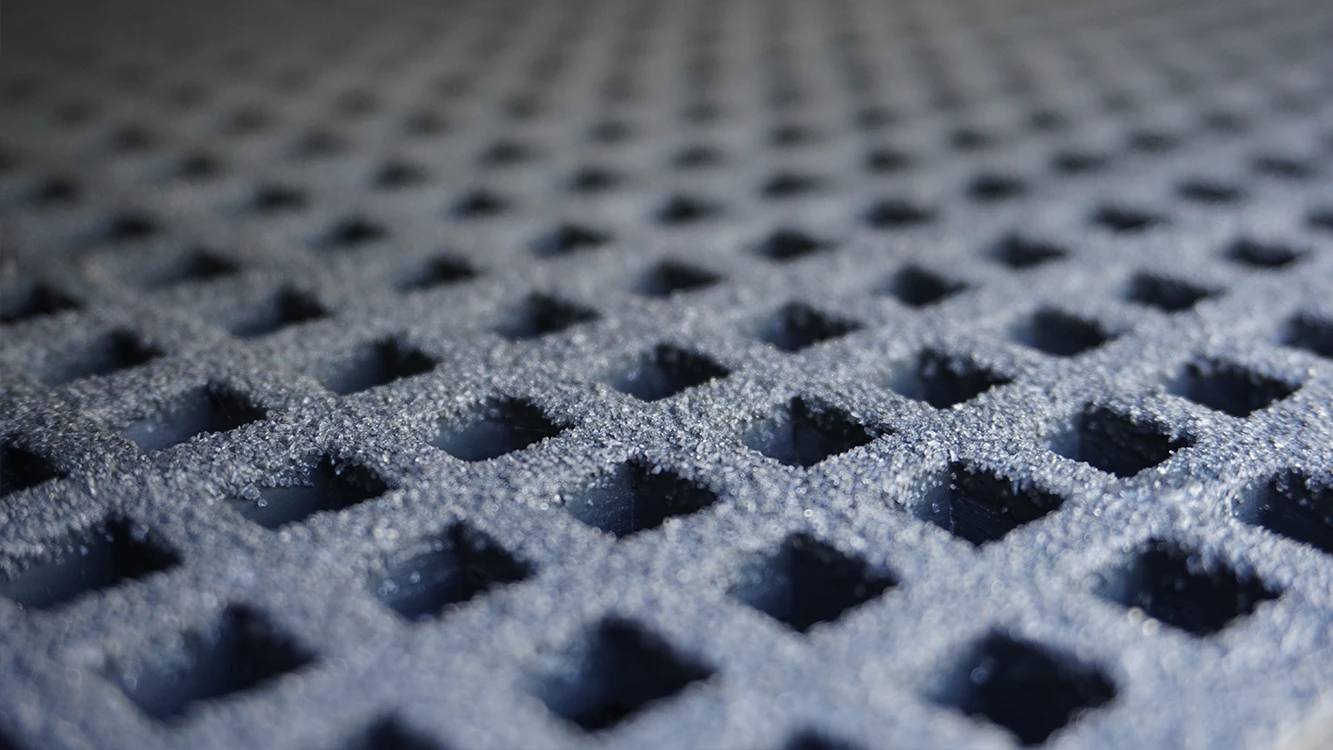

Winners of three King’s awards, Dura Composites’ fully recyclable d² product range includes walkway grating, trench covers, structural profiles, handrailing, high-rise balcony decking, access structures, and station platforms. Designed with sustainability at their core, these unique products incorporate weight-reducing innovations that simplify on-site logistics and reduce environmental impact by minimising embodied carbon. Uniquely, our d² products are fully recyclable at the end of their lifecycle, aligning with our commitment to a circular economy.

Our Purpose: The Lowest Carbon Walkways in the World, to Best Preserve our Planet.

Our commitment to innovation and sustainability ensures that businesses can achieve their net-zero goals without compromise. Our purpose is clear, by pioneering the world’s lowest carbon walkways, we’re redefining sustainable infrastructure – delivering safer, stronger, and greener solutions that are proven to support a better future for all.