Certificates

EPD For Porcelain Decking

This is an Environmental Product Declaration in accordance with EN 15804+A2 & ISO 14025 /…

DownloadGeneral Sales | +44 (0) 1255 446838

Sales Support | +44 (0) 1255 423601 (Option 5)

Transport | +44 (0) 1255 462567

Rail | +44 (0) 1255 440291

Industral & Commercial | +44 (0) 1255 440290

High-Rise | +44 (0) 1255 446830

Decking & Cladding | +44 (0) 1255 440298

Marine | +44 (0) 1255 440297

Intelligently carbon-engineered

Verified environmental data

Transparent lifecycle assessment

Responsible operational practices

Dura Composites designs and manufactures composite walkway and access systems supported by third-party verified Environmental Product Declarations (EPDs).

Our products provide embodied carbon data suitable for specification, whole-life carbon assessment and Scope 3 reporting across infrastructure projects.

The d² composite range is carbon-engineered by design, fully repurposable at end-of-use, and supported by lifecycle assessment data prepared in line with recognised international standards.

We specialise in delivering the world’s lowest‑carbon walkways and access systems, to best preserve our planet. Designed to help infrastructure projects meet net‑zero targets with confidence, our solutions combine advanced engineering with verified carbon data to enable greener construction without compromising performance.

Our industry‑first repurposing process gives end‑of‑use GRP a second life by transforming it into new composite material at our UK headquarters. This closed‑loop approach reduces waste, lowers reliance on virgin resources, and supports more sustainable long‑term asset strategies.

Our sustainability efforts extend beyond products. With a FORS Gold accredited fleet, reusable bearer packaging, pallet‑free logistics wherever possible, and a 96% electric‑inclusive vehicle fleet, we actively cut emissions, reduce site waste, and improve efficiency across our operations.

Our d² composite product range is intelligently carbon-engineered at source, using material efficiency, modular design and advanced manufacturing processes to minimise impact across the product lifecycle and support more responsible long-term asset strategies.

We provide verified product data, standards alignment and material intelligence to support early design decisions, embodied‑carbon assessments and credible Scope 3 reporting without adding risk.

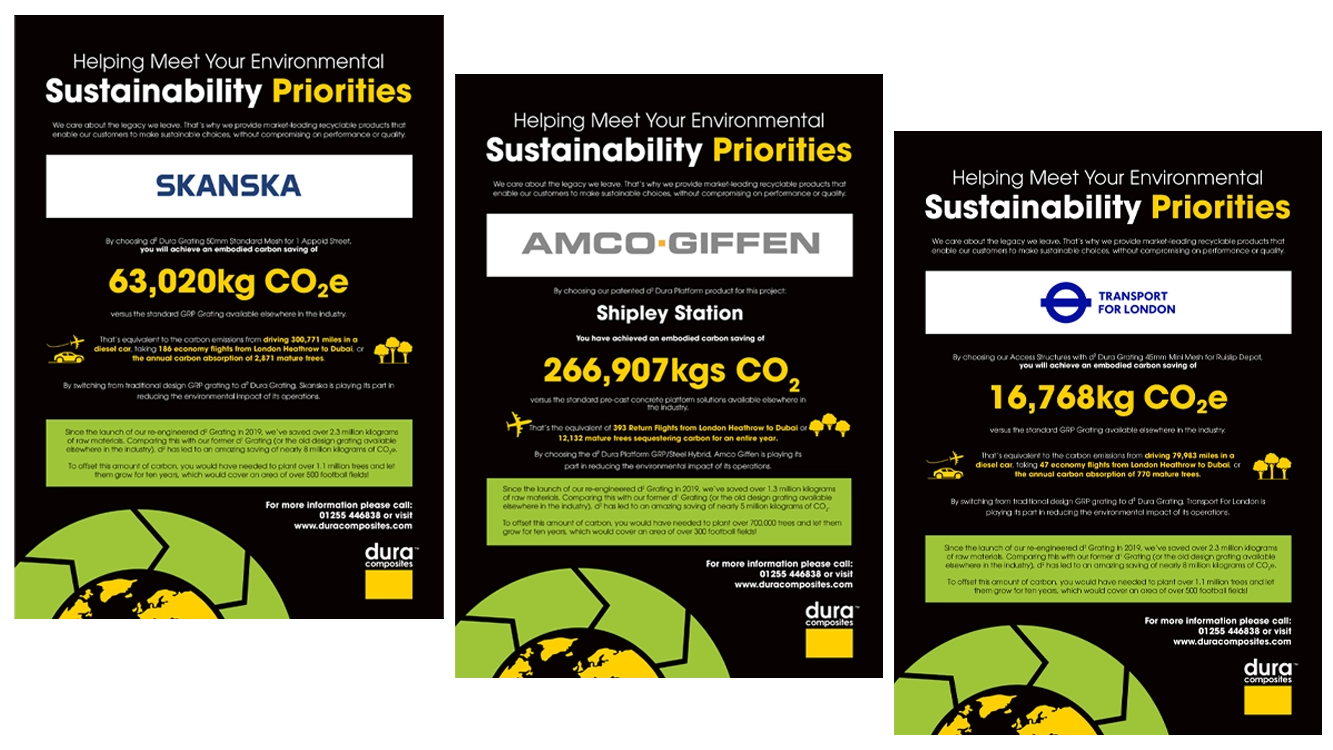

When required, we can produce project‑specific embodied‑carbon calculations for individual d² walkway products, using verified data that works with recognised assessment methodologies.

Our embodied‑carbon values for moulded and pultruded GRP and aluminium support whole‑life carbon assessments, project‑level calculations, informed material selection, sustainability reporting and alignment with environmental frameworks. This helps specifiers, consultants and contractors demonstrate due diligence and meet reporting obligations.

For guidance on reducing risk and simplifying composite specification across RIBA and PACE stages, designers and engineers can visit our Design Support page here.

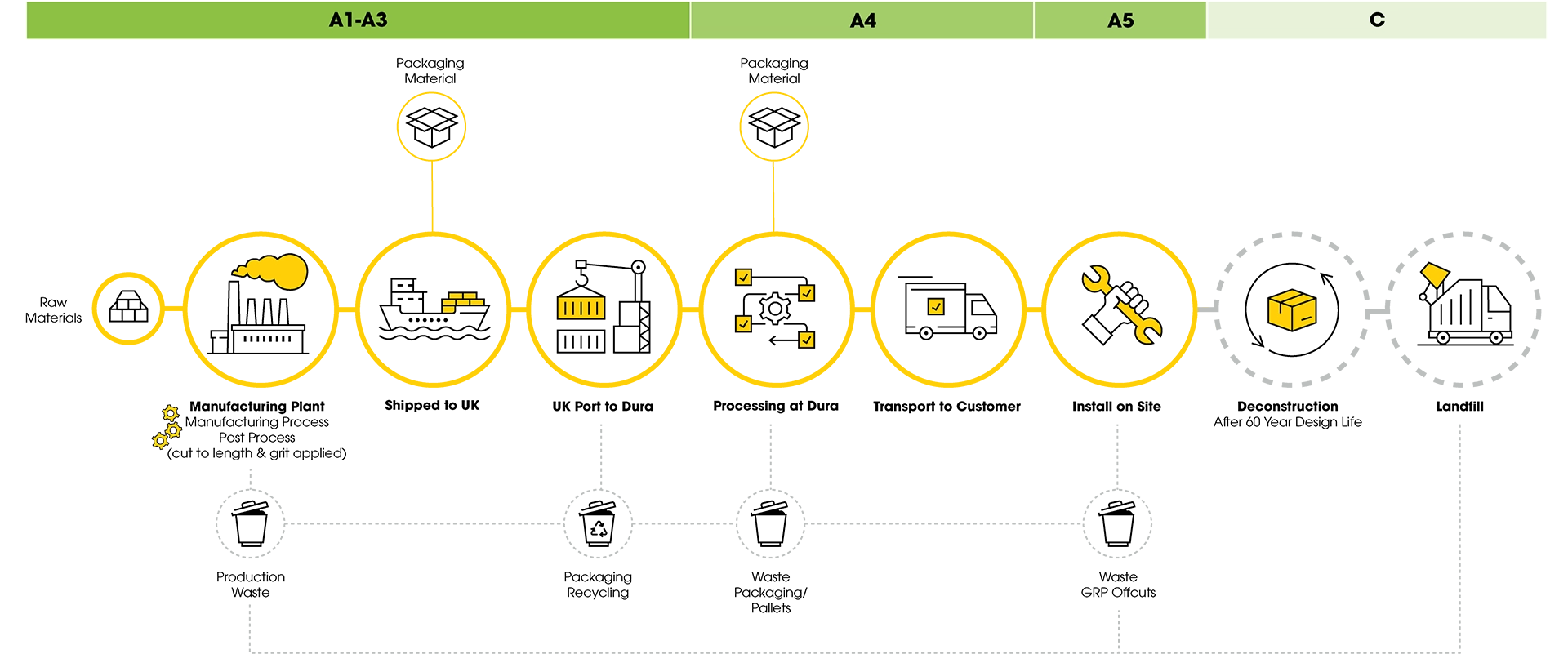

Whole life carbon refers to the total carbon emissions produced throughout the lifecycle of an asset or piece of infrastructure. These emissions come from the energy used to extract, transport and process raw materials, and to manufacture them into products used to build, maintain and renew assets. This is often known as Cradle to Gate.

To support transparency and measurable progress, we provide independently verified EPDs across our d² product range. These verified EPDs support accurate carbon reporting, strengthen project level sustainability planning and ensure alignment with recognised frameworks such as BREEAM, LEED and PAS 2080. Through this data led approach, we equip our customers with trusted insights to confidently monitor, manage and reduce their carbon emissions.

Our EPD results have a cradle-to-gate scope, comprising raw materials extraction and supply (A1), transport (A2) and manufacturing (A3). The yellow highlights indicate the stages Dura Composites is involved in throughout the journey of the product.

Certificates

This is an Environmental Product Declaration in accordance with EN 15804+A2 & ISO 14025 /…

Download

Certificates

This is an Environmental Product Declaration in accordance with EN 15804+A2 & ISO 14025 for…

Download

Certificates

This is an Environmental Product Declaration in accordance with EN 15804+A2 & ISO 14025/ISO 21930…

Download

Certificates

This is an Environmental Product Declaration in accordance with EN 15804+A2 & ISO 14025/ISO 21930…

Download

Certificates

This is an Environmental Product Declaration in accordance with EN 15804+A2 & ISO 14025/ISO 21930…

Download