A Proven, Sustainable Platform Solution

To meet these objectives, AmcoGiffen selected d² Dura Platform 40, Dura Composites’ Network Rail-compliant Glass Reinforced Polymer (GRP) platform system. Offering a clear span of up to 1.5m, weight of just 35.55 kg/m², and a 5 kN/m² load performance at L/300 deflection, Dura Platform 40 delivers the strength and durability of traditional materials with a fraction of the embodied carbon.

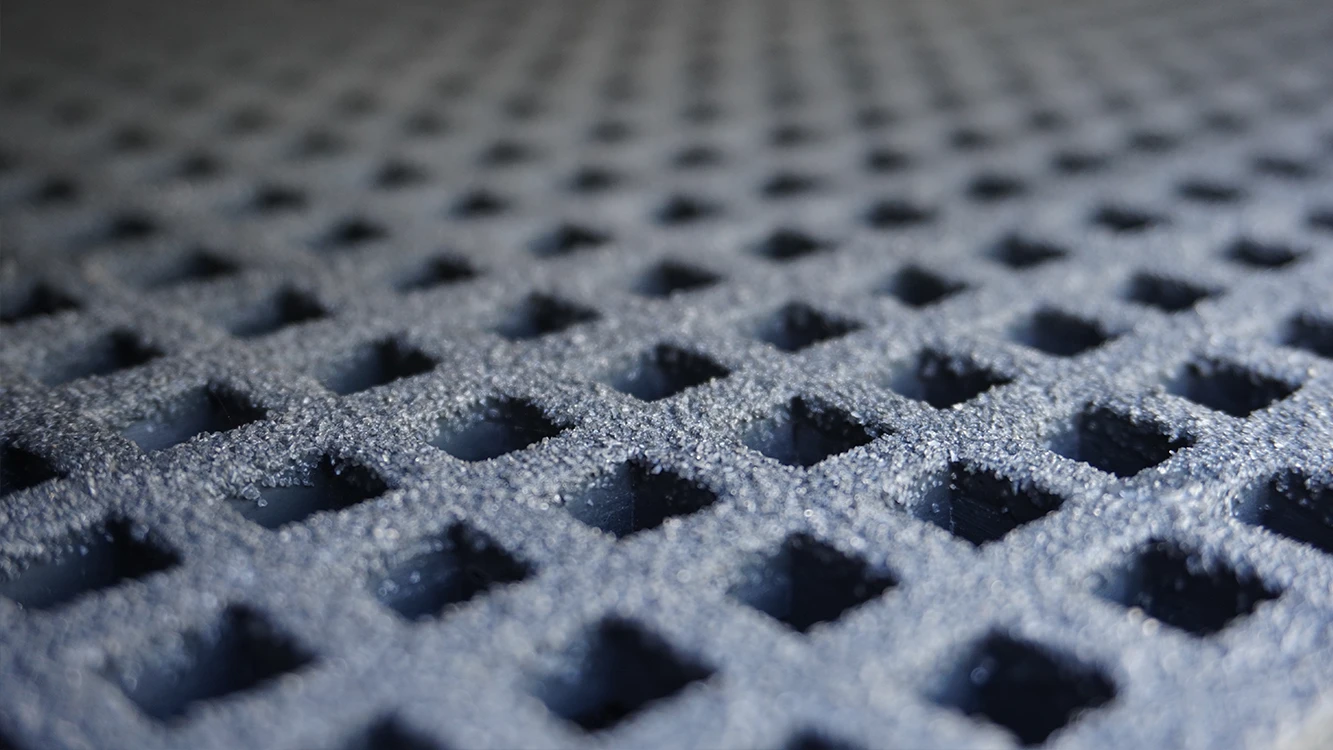

The modular design allowed the new platform extensions to be installed rapidly and safely without the need for heavy lifting equipment, reducing both site risk and possession time. The Tri-Tone Grit surface, tested to BS 7976-2:2002 + A1:2013, retained over 97% of its slip resistance after 1.1 million footfalls, ensuring long-term safety and performance for passengers in all weather conditions.

The GRP system also supports Network Rail’s sustainability and circular economy goals, with a 60-year design life and a full end-of-life repurposing programme through Dura Composites’ mechanical recycling process.

Safe, Durable Access with d² Dura Profile

Complementing the new platform system, End of Platform steps and landings were fabricated using d² Dura Profile, Dura Composites’ market-leading structural section range engineered for superior strength, durability, and low maintenance.

The lightweight yet high-stiffness GRP profiles provided a corrosion-resistant alternative to steel, perfectly suited to the exposed rail environment. Pre-engineered components enabled rapid assembly and precise fit-up on site, while the anti-slip finish ensured long-term safety for operational staff and passengers alike.

Together, d² Dura Platform 40 and d² Dura Profile delivered a complete, integrated access and platform solution — reducing whole-life cost, improving sustainability, and extending the operational lifespan of the station infrastructure.

Carbon and Environmental Impact

Replacing conventional concrete and steel with the d² GRP systems significantly reduced the embodied carbon footprint of the scheme. Based on comparative data across concrete platform installations, the solution delivered up to 597 tonnes of CO₂e savings, equivalent to removing 53 HGVs from the road or offsetting the annual carbon sequestration of over 27,000 trees.

These outcomes demonstrate the tangible benefits of early collaboration between Network Rail, AmcoGiffen, and Dura Composites, engaging the supply chain to achieve measurable Scope 3 carbon reductions in line with PAS 2080 principles.

View the carbon saving certificate