Addressing the limitations of steel grating with a phenolic GRP solution

The purpose of the bund is to provide safe and practical access to the plant while effectively preventing the spread of burning oil. To achieve this, its components must possess adequate strength, durability, and fire resistance.

Although steel-punched grating can restrict oxygen flow and aid in extinguishing fires, it presents several practical challenges. These include complex earthing requirements, a limited lifespan, and the difficulties associated with regular inspections.

For this reason, Dura Composites collaborated with our clients to provide a phenolic GRP Dura Grating system to address the shortcomings of steel grating which was tailored to the substation’s requirements.

Key features of the phenolic GRP pultruded grating 50mm T-Bar Dura solution

In terms of fire resistance, phenolic GRP has been rigorously tested and validated under USCG E-119 standards. Unlike other materials, it does not liquefy when exposed to fire. During testing, the grating successfully endures temperatures of 927°C for a duration of 60 minutes without failure, highlighting its exceptional resilience.

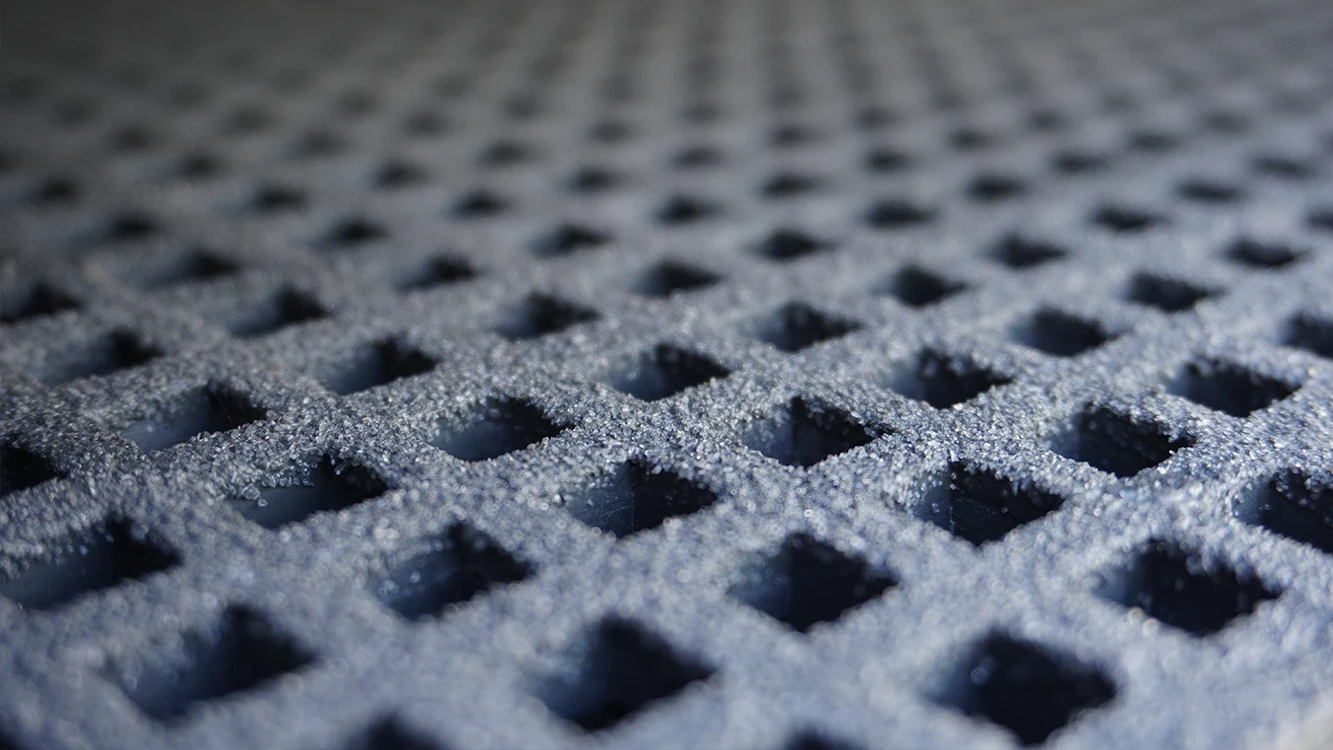

This solution met the high-performance standards of the project at the time of installation, boasting a 33% open area for drainage while complying with stringent safety and performance criteria.

These include the UK fire safety standards:

- BS 476 Part 7 Class 1 (Surface Spread of Flame)

- BS 476 Part 6 Class 0 (Fire Propagation)

- BS 6853:1999 Annex D8.4 (Smoke Emission Test).

Additionally, it adheres to the following international standards:

- ASTM-E84 (Flame Index 10, Smoke Index 135)

- ASTM-E119 (Fire Resistance)

- ASTM-D635 (Zero Burn Rate)

- ASTM-D2394-2011 (Static Slip Resistance 0.93, Dynamic Slip Resistance 0.82).

Durability was another key feature of the phenolic GRP, offering exceptional resistance to wear and tear. This reduces the frequency of replacements and minimises long-term maintenance costs, making it a cost-effective solution over time.

Finally, the ease of installation enhances its appeal. The GRP panels were installed on steel beams and securely fixed using Dome Washers and G-Clamps. This ensured a stable and reliable installation process, further underscoring its practical benefits.

In certain projects of this type, it is worth noting that the bund may also include a layer of 20mm single-sized washed rounded gravel, with a depth ranging from 75mm to 300mm. For calculation purposes, the air volume within the gravel, which can accommodate any spilled material, is considered to be 25% of the gravel’s total volume.