Why invest in corrosion-resistant materials

Corrosion-resistant materials are particularly crucial for industries exposed to saltwater, chemicals, or extreme temperatures. Corrosion-resistant materials are widely used across many industries for many reasons, including the following key drivers:

- They prevent structural damage – corrosion weakens metals, causing cracks, leaks, and failures in bridges, buildings, pipelines, and vehicles. Corrosion-resistant materials like stainless steel and GRP, however, provide a longer-lasting, more durable alternative. Preventing corrosion helps avoid accidents, leaks, and structural collapses, so they’re a much safer option too.

- They reduce maintenance costs – frequent repairs and replacements due to corrosion can be expensive. Corrosion-resistant materials reduce maintenance needs, saving money over time.

- They have a longer lifespan – not only does flooring or installation made from corrosion-resistant materials last much longer in certain environments, if you opt for a composite like GRP, they also have a longer lifespan than traditional materials even without taking the harsh environments into account.

What corrosion-resistant materials are available and which should you choose?

It’s important to think about the requirements of your particular project, and consider materials that can withstand these unique conditions, but here are some popular corrosion-resistant materials.

Stainless steel

Stainless steel is one of the most commonly used corrosion-resistant materials due to its durability, strength, and resistance to rust and oxidation. It contains chromium, which forms a passive oxide layer that protects the metal from corrosive elements. Grades such as 316 and 304 stainless steel are widely used in chemical processing, marine environments, and food production industries.

Whilst stainless steel is extremely strong, it’s not as flexible as other choices such as GRP, so think about what your project demands. It’s also much heavier than GRP, which may impact installation, especially in less accessible applications.

Titanium

Titanium is highly resistant to corrosion, particularly in harsh environments like seawater, acidic solutions, and chlorine exposure. Its strength-to-weight ratio makes it ideal for aerospace, medical, and chemical processing applications. Titanium does not corrode in many aggressive chemicals, making it a preferred choice for industries that deal with highly reactive substances.

Titanium is lighter than steel but still heavier than GRP. It’s also much more expensive.

Nickel alloys

Nickel-based alloys, such as Hastelloy and Inconel, offer excellent corrosion resistance in extreme conditions, including high temperatures and acidic or alkaline environments. These alloys are commonly used in the aerospace, nuclear, and chemical processing industries due to their ability to withstand harsh environments without degradation.

They are lighter than some materials, but heavier than GRP, and like titanium are more expensive.

Aluminum and aluminum alloys

Aluminum naturally forms a protective oxide layer that shields it from corrosion. It’s strong but still relatively lightweight compared to materials like steel and other metals, making it ideal for applications where weight reduction is crucial, such as in transportation and aerospace. Certain aluminum alloys offer enhanced corrosion resistance and are used in marine, construction, and chemical industries.

Aluminium and aluminium alloys however do require protective coatings or anodising in extreme environments, and can suffer from oxidation or corrosion if exposed to saltwater or acidic conditions for too long. It’s also more expensive than GRP, which is why GRP is often favoured in marine environments.

GRP

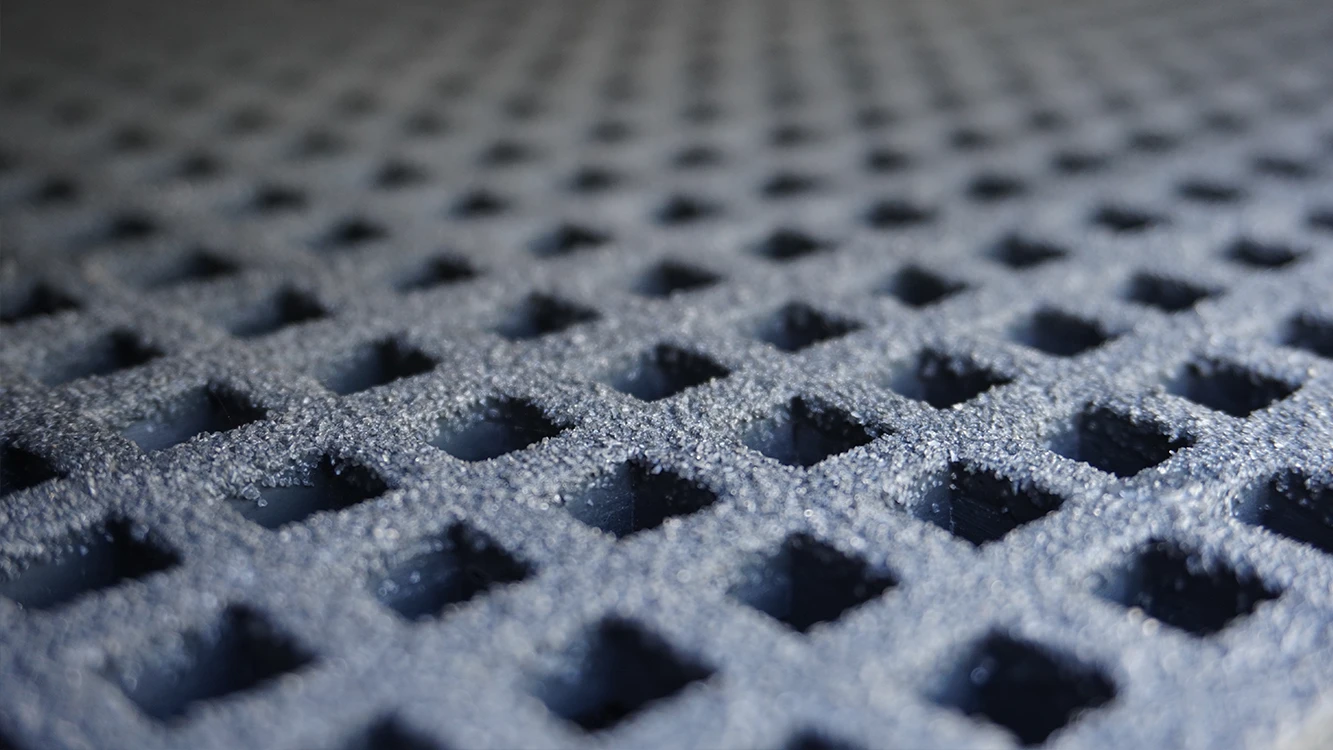

GRP (Glass reinforced polymer) is an excellent choice for industrial projects that require corrosion-resistant materials. It is widely used in chemical processing, wastewater treatment, marine, and oil and gas industries due to its resistance to moisture, saltwater, chemicals, and extreme environments.

Unlike metals, GRP does not react with acids, bases, or harsh chemicals. It also does not rust, corrode or oxidise.

One of its biggest advantages is its strength-to-weight ratio. Much lighter than materials such as stainless steel, it is therefore much easier to transport, manoeuvre and install, saving both time and money. These cost savings are then maximised by the fact that GRP does not require protective coatings, paint or frequent repairs.

Because GRP is also resistant to UV and temperature variations, and can be moulded into complex shapes, it is used for a wide range of applications and sectors, from covers and piping in the oil and gas industry, to grating within marine and offshore applications.

In addition to the benefits above, we’ve created a new generation of GRP products, known as d². Designed, developed and available exclusively from Dura Composites, this patented range offers the same outstanding safety, performance and durability, but with up to 33% less embodied carbon.

Choosing the right corrosion-resistant material for your industrial infrastructure project will depend on a number of factors such as the environment, application requirements, and cost. Selecting the appropriate material can improve longevity, enhance safety, and reduce maintenance costs, ultimately ensuring more efficient and reliable operations. Our composite experts will be happy to help guide you towards the right choice for your needs.