Is GRP grating better than steel grating?

Well we certainly think so, but don’t just take our word for it, let’s examine the different factors below:

Ease of fabrication – while steel requires heavy machinery and skilled labour for fabrication, welding, and installation, GRP is easier to mould into complex shapes during the manufacturing process, making it versatile for intricate designs.

Strength – steel is famous for its high strength, ideal for heavy structural and load-bearing applications as it’s able to withstand significant stress and weight. While traditional GRP grating isn’t as strong as steel, our d² range of GRP grating has an unrivalled performance-to-weight ratio.

Weight – where steel is inherently strong, it’s also dense and heavy, which can be a limitation for applications where weight is critical. GRP on the other hand is much lighter than steel. Our d² range of GRP grating is up to 33% lighter than traditional GRP grating but just as strong. Not only does this make it easier to transport and install, it also saves you money, through speed and the requirement of fewer workers.

Safety – the fact that GRP is lighter also makes it safer to install, but beyond this, GRP has additional safety benefits. GRP grating often has gritted anti-slip surfaces, making it much more suitable for applications across particular industries such as the marine sector where slips and trips are the number one hazard.

Corrosion resistance – steel is prone to rust and corrosion unless properly treated and usually requires maintenance and coatings for harsh environments. Because GRP is naturally corrosion-resistant, it’s ideal for marine, chemical, or outdoor applications where exposure to moisture or chemicals is high.

Thermal and electrical conductivity – steel has high thermal and electrical conductivity, which can be a disadvantage in certain applications. GRP, on the other hand, is non-conductive to electricity and has low thermal conductivity, offering safety advantages in electrical and thermal insulation applications including rail walkways.

Lifespan – GRP products are typically longer-lasting than steel products, often by a considerable margin, especially when it’s installed somewhere with harsh conditions.

Sustainability – steel is fully recyclable, contributing to sustainability efforts. GRP historically was not recyclable, however, at Dura, we have begun recycling end-of-use GRP grating. In addition, GRP’s long lifespan reduces frequent replacement needs.

Maintenance – GRP grating requires little to no maintenance over the course of its life cycle, so it’s the clear choice over steel in this category, especially for use in applications in certain environments including rail and marine.

Cost – while steel may sometimes be cheaper upfront, long-term costs may increase due to maintenance. GRP often has a higher initial cost, but lower long-term maintenance costs and a longer lifespan making it the more cost-effective option overall.

All of these features can make GRP more suitable for infrastructure projects.

We provided phenolic GRP bund flooring for Hornsea Wind Farm Onshore Substation, 75 miles off the North East Lincolnshire coast. A traditional steel grating system would include complex earthing requirements, a limited lifespan, and be tricky to access and maintain. We used GRP to overcome these challenges and meet strict safety and performance standards. Find out more about the project here.

What are the different types of fibreglass grating?

There are several types of fibreglass grating, also known as GRP grating, with each designed for specific applications and conditions. Let’s run through the main types:

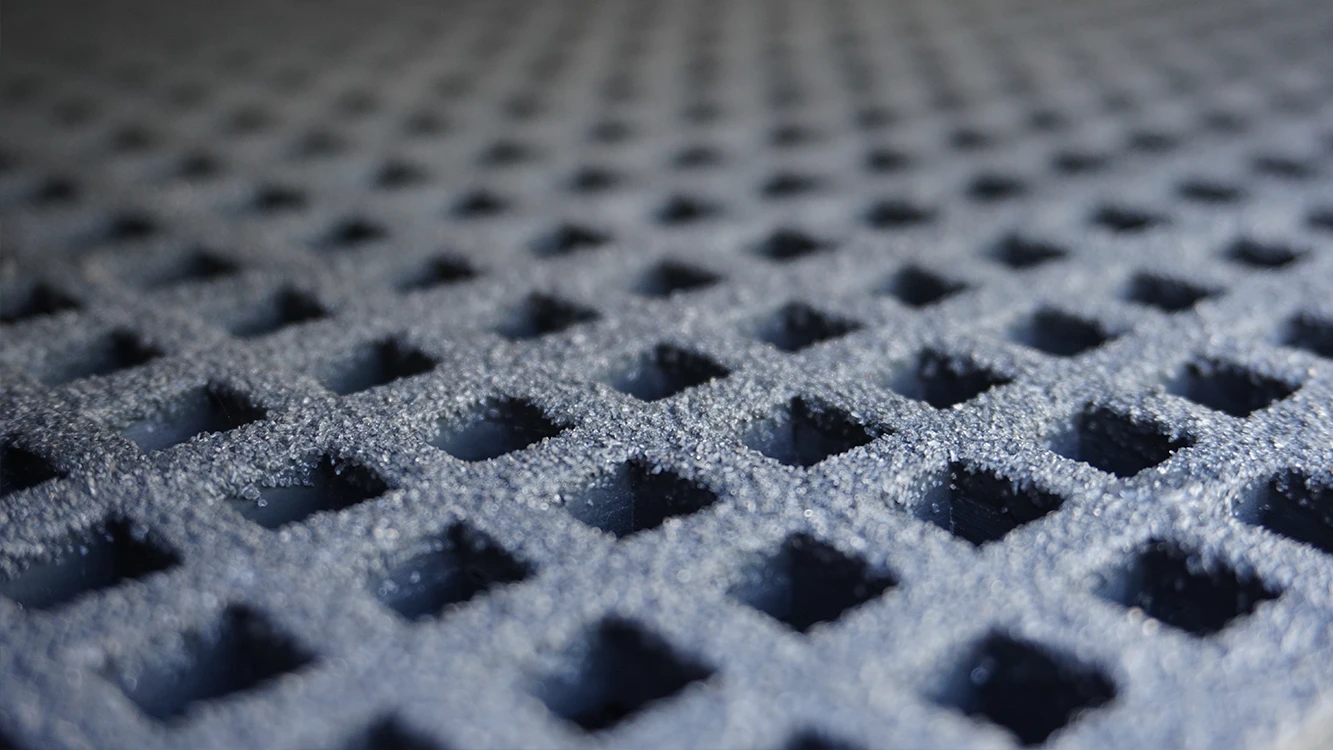

Open mesh

Open mesh grating is moulded grating, which is made by combining resin and fibreglass in a mould, creating a one-piece, integral construction. The open mesh design is uniform and provides multidirectional strength. Open mesh GRP grating comes in different sizes:

1. Standard mesh

Available in thicknesses of 26mm, 38mm and 50mm, standard mesh GRP grating creates safer environments for platforms, walkways, flooring, ramps and covers.

2. Mini mesh

Available in 45mm and 55mm, mini mesh GRP grating has a smaller hole size, promoting efficient drainage while providing a secure footing. It’s commonly used for areas of pedestrian foot traffic, including riser voids, raised walkways and marinas.

3. Micro mesh

With all the benefits of mini mesh grating but with an even smaller hole size, micro mesh grating is ideal when moving wheeled vehicles and equipment. It has a finer gritted surface and is the most pedestrian-friendly grating, often used for leisure facilities.

Solid top

Solid top grating, also known as covered fibreglass grating, features a solid surface that is laminated over moulded or pultruded grating, creating a smooth and secure walking surface. As well as preventing objects or debris from falling through, it also reduces slips and falls.

Pultruded

Pultruded GRP grating is manufactured by pulling continuous fibreglass rovings through a resin bath and then shaping them into profiles, which are then assembled into panels. It delivers unidirectional strength and is often used for industrial rail, chemical, nuclear, and power and energy applications.

Which type of grating is the best?

The best type of grating is the type that is best suited to your particular project, but if you’re looking for a material that’s easily manoeuvred and installed, with an excellent strength-to-weight ratio, a long lifespan and is cost-efficient, then GRP grating is probably the right choice. This is especially true when it comes to infrastructure in certain environments like rail, marine, energy and power, where challenging conditions demand additional features such as corrosion resistance and non-conductivity. Don’t forget to think about load requirements and regulatory compliance too.

The type of surface you require will also be dictated by your needs. Think about where it will be used, whether you need protection against falling objects and debris, if it needs to be pedestrian-friendly, or cleanable, and whether you require unilateral or bilateral strength.

If you need advice choosing the right type of grating for your next project, please get in contact and our experts will be more than happy to speak to you. You can order samples of our GRP grating products here.