Cleaning GRP: the basics

For most situations, cleaning with a bristled brush and hot soapy water or any road traffic film cleaner will effectively remove dirt and dust from your d² GRP components.

- Scrub cleaning fluid made to correct concentration onto the affected area using a soft-bristle brush.

- Leave the solution for 10-15 minutes to work.

- Jet wash the solution off thoroughly.

- For stubborn areas, repeat the entire process.

- Remove dirty water using a wet vacuum or squeegee, directing it to the appropriate floor drains in line with local regulations.

Note that contaminated water may require disposal as hazardous waste. Always observe regulations prohibiting the introduction of chemical cleaners, solvents, and wastes into surface water drains, sewer systems, or natural water bodies.

Pressure washing and steam cleaning GRP

More stubborn grime may require high-pressure washing. Always follow the safety guidelines outlined below, and provide proper training for powerful cleaning equipment to ensure it is used safely.

Before pressure washing or steam cleaning, sweep the floor to remove loose debris and soil accumulations. Pre-wet the floor surface, and select the appropriate cleaning agents for your equipment (detergent, deodoriser, degreaser, emulsifier, or bactericide).

- Apply cleaning agents following manufacturer guidance and specified dilution rates, and allow the chemicals to react on the surface.

- Work the entire floor surface systematically using your pressure washer or steam cleaner.

- Flood with clean water and work over the surface again.

- Rinse thoroughly and remove all residue.

Safety limits: Use pressure washers up to 1500 psi maximum. Keep the nozzle at least 25cm (10 inches) from the surface and avoid concentrated spraying on any single area for more than 3 seconds.

Targeted solutions for cleaning GRP

General dirt and debris

Apply an alkaline detergent solution with a brush and spray with a hose to remove surface debris. Use warm, soapy water and a bristled brush to clear debris from grooves and contours. Stubborn stains may require pressure washing.

Mould and mildew

Mould and mildew thrive on surface residue left on GRP. Remove and brush affected areas immediately, then spray with a hose and clean with warm, soapy water and a soft-bristle brush. Pressure wash persistent stains where necessary.

Oil, grease, food, and drink

Quick action is crucial for contaminants such as oil, grease, food, and drink. As with mould and mildew, remove and brush spills immediately, spray with a hose and clean with warm, soapy water and a soft-bristle brush, pressure washing for stubborn residues.

Ice and snow removal

It’s important to clean salt residue promptly to prevent long-term effects. Use plastic shovels or brooms (never metal tools) to remove snow, and apply salt as required.

Cleaning GRP best practices

WHAT TO DO

- Conduct an initial clean before putting your d² GRP products into use.

- Establish a regular cleaning schedule appropriate to your environment.

- Increase maintenance frequency for high-traffic areas like entrances, where grit, dirt, and wear are highest.

- Clean up spillages immediately, especially oil and grease.

- Maintain higher cleaning standards in areas prone to chemical, bacteriological, or radioactive contamination.

- Use brushes rather than mops for optimal results.

- Invest in high-quality cleaning equipment.

- Keep all cleaning equipment properly maintained and regularly cleaned.

- Always follow manufacturer instructions for chemicals and equipment.

WHAT TO AVOID

- Never exceed manufacturers’ recommended cleaning agent concentrations.

- Never use solvents on your d² GRP products.

- Avoid phenol-based cleaning chemicals as they will degrade d² Dura products.

- Don’t use synthetic scrubbing pads on textured resin finishes.

- Avoid using excessive amounts of water.

- Don’t ignore manufacturer instructions for cleaning chemicals.

Maintaining your warranty

The correct cleaning regime for your specific product depends on site conditions and application requirements. Environmental factors, traffic patterns, and exposure to contaminants all influence your optimal maintenance schedule.

To preserve your product warranty, ensure your cleaning methods align with the guidelines outlined in this article and consider the specific demands of your installation environment.

Remember that while d² Dura GRP products are designed for minimal maintenance, establishing the right cleaning routine from the start will maximise their lifespan and performance. When in doubt about specific cleaning challenges or unusual contamination, consult with our technical support team for guidance tailored to your situation.

By following these comprehensive guidelines, you’ll ensure your d² Dura GRP products continue to deliver exceptional performance and maintain their appearance for years to come.

Debris Removal in Riser Environments

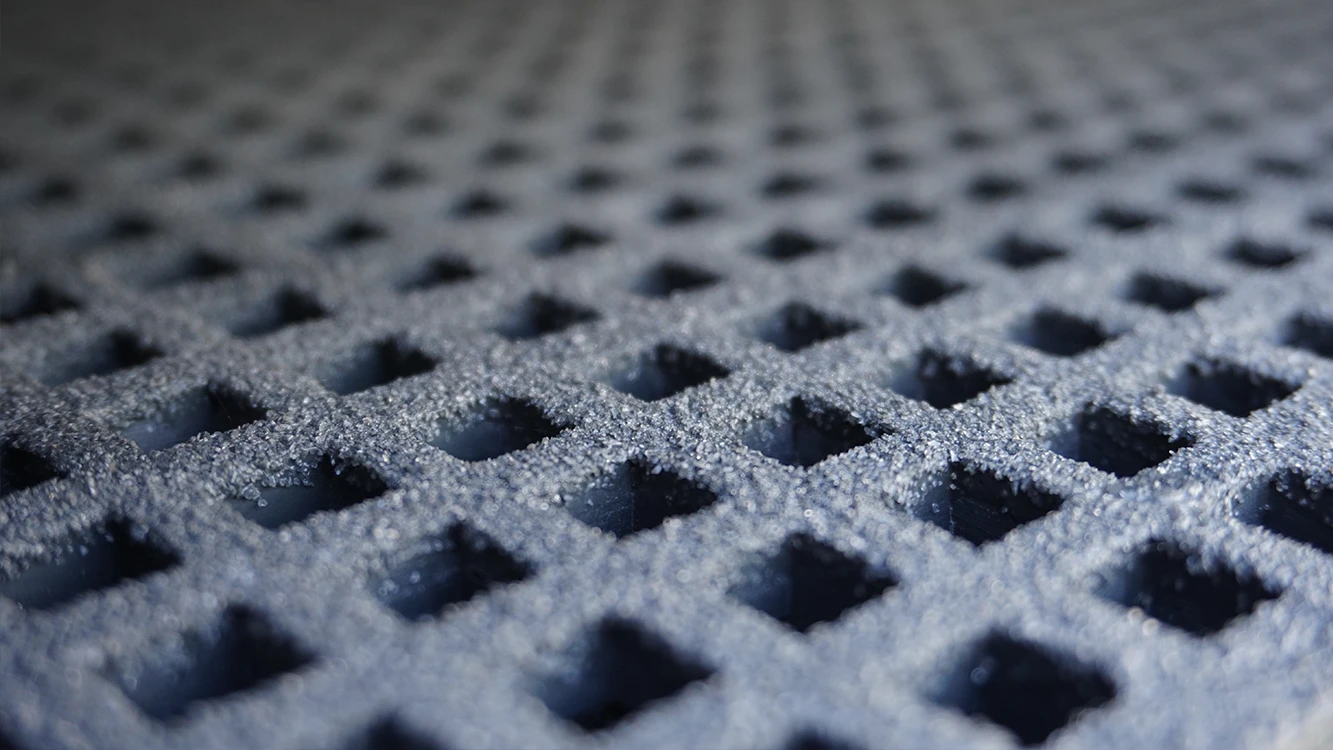

Wet cleaning methods are not suitable in riser environments. To maintain a safe and compliant riser space, debris must be removed in a controlled way to prevent any loose material or fine particles falling through the open mesh.

Large debris must be collected by hand while wearing suitable task-appropriate gloves to ensure safe handling and to avoid dislodging material into the riser void.

Finer particles should then be removed using an M-class vacuum, which provides the necessary filtration to capture dust and prevent redistribution within the space.