Datasheets

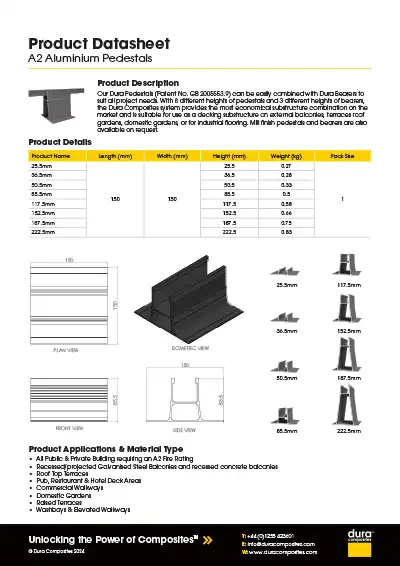

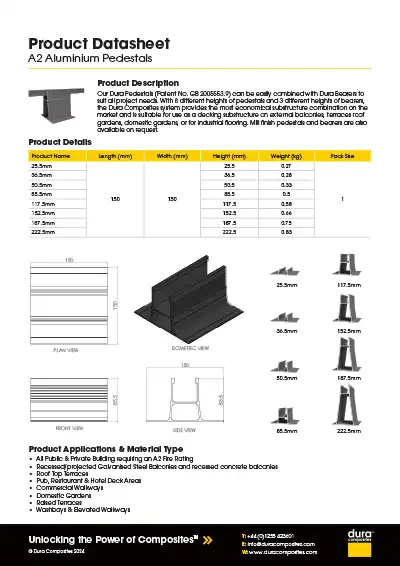

A2 Aluminium Pedestals

Our Dura Pedestals (Patent No. GB 2005553.9) can be easily combined with Dura Bearers to…

DownloadThe Decking & Cladding Team | +44 (0) 1255 440298

General Sales | +44 (0) 1255 446838

Sales Support | +44 (0) 1255 423601 (Option 5)

Transport | +44 (0) 1255 462567

We offer a market-leading alternative to traditional wood decking. Our class B fire-rated composite decking boards give you the look and feel of real wood with none of the downsides. So you can create a long-lasting, beautiful outdoor space without the worries (or work) that come with installing timber boards.

Whether you’re planning a commercial or residential decking project, Dura Composites has a durable, simple-to-install, cost-effective and environmentally friendly solution to help maximise the use of outdoor space in all seasons. Our high-performance composite decks combine fade-resistance with outstanding durability meaning you can spend less time maintaining your deck and more time enjoying it. Our composite decking range, Dura Deck Flip, is a stunning product that takes two complementary colours and combines them into one single decking board profile to help you create clever deck designs.

Composite timber decking (sometimes called WPC decking) is a unique blend of recycled plastics and wood materials that create a strong, durable, beautiful-looking alternative to timber. The reinforced properties mean that composite decking has a host of advantages over timber, which make it a far more suitable option for creating a gorgeous outdoor space. It’s hard-wearing, strong, lightweight, and ultra-resistant to the elements, ensuring it looks its best from installation onwards. The unique composition also gives our composite decking an advantage in slip, fire, and mould resistance – protecting the space, and the people that use it, for decades!

You may not believe us when we say that composite decking boards have virtually no disadvantages when compared to timber decking – but it’s true! Our boards look and feel exactly like wood, so you can create an outdoor space that looks traditional, but does not suffer from any of the drawbacks of timber. Say goodbye to fixing, brushing, wiping, staining and painting; with high-quality composite materials, you’re guaranteed a deck that looks perfect all-year-round, and only requires the minimal amount of maintenance to look its best.

Our decking boards are created with up to 87% recycled materials, guaranteeing an environmentally conscious product.

Designed and tested to meet the demanding specifications (high-rise or multi-occupancy buildings) of BS EN 13501 Class Bfl-s1 as part of a Broof(t4) scheme.

The fantastic wood effect surface features a unique finish that allows the product to achieve low slip potential in dry or wet conditions.

Our unique 360° outer armour ensures strength, protects against staining, resists fading and effectively manages contraction and expansion.

Dura Deck Flip Resist comes in lengths of 3.66m and is easy to install with the help of a professional, or with some DIY knowledge. This job is made easier by the innovative subsurface fixing system, meaning you won’t need screws or nails to fix the boards in place – leaving a perfect, clean, barefoot friendly deck. What’s more, each of our composite decking boards come with a 15 year warranty, so you can be confident of quality through thir service life.

Our latest advancements in decking technology mean that you can get a deck that has the look and feel of natural timber, with none of the awkward or expensive downsides. Both colours on the ‘Flip’ boards are tested to withstand weather, scratching and stains, so you’ll never need to treat or repaint them to keep them looking their best – saving you money on products and giving back time to enjoy your gorgeous outdoor space.

Our Flip decking is available in Pebble Grey/Weathered Cedar, meaning you can create an attractive, unique deck design any way you want. Start with one contemporary style for half the year then flip it over at a later date for a whole new look – or combine the two for a truly original aesthetic.

Using materials with high recycled content is one of the best ways to reduce environmental impact, but this doesn’t have to mean compromising on quality. Our ethically sourced composite wood products made with recycled materials offer excellent durability and performance, making them ideal for projects that prioritise environmental responsibility. By choosing composite cladding and decking products that incorporate recycled content, you contribute to waste reduction and support a more sustainable future.

Our A2 fire-rated Dura Pedestals and Dura Bearers can be easily combined to suit all project needs, offering a superior alternative to timber subframes that can twist, rot, or warp over time. With varying heights of pedestals and bearers, our system provides the most economical substructure combination on the market. The Dura Aluminium System is suitable for use as a decking substructure on external balconies, terraces, gardens, industrial flooring and for use as cladding battens.

Explore our solutions and services to help you build resilient, greener and safer infrastructure.

Datasheets

Our Dura Pedestals (Patent No. GB 2005553.9) can be easily combined with Dura Bearers to…

Download

Datasheets

Our Dura Bearers can be easily combined with Dura Pedestals to suit all project needs.…

Download

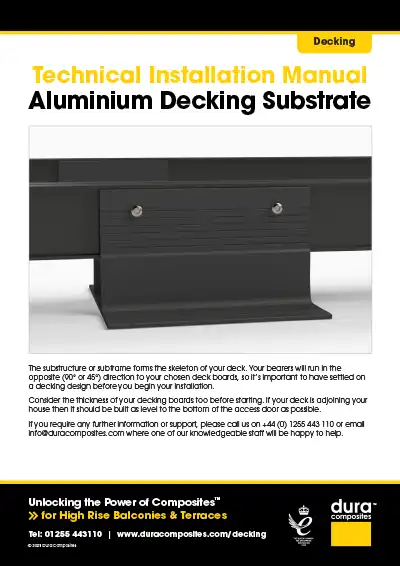

Installation Manuals

The substructure or subframe forms the skeleton of your deck. Your bearers will run in…

Download

Installation Manuals

Dura Deck Technical Manual for installation instructions and support for our composite decking.

Download

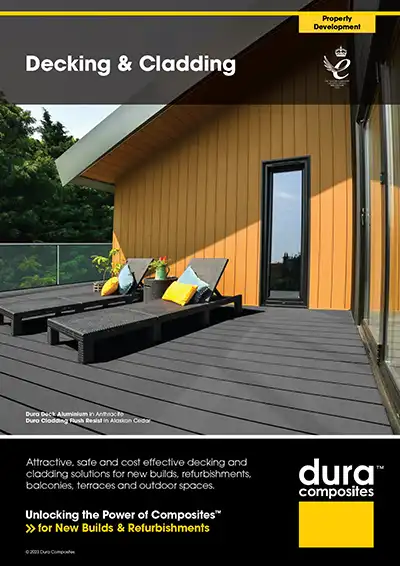

Attractive, safe and cost effective decking and cladding solutions for new builds, refurbishments, balconies, terraces…

DownloadFind out how our market-leading composite products and applications are reshaping the industry.

Talk to our experienced team about how you can tap into our specialist knowledge and engineering capability for your project.