Flyers

Envirosump

Train washing is an essential part of the daily routine for train operating companies. New…

Download

Rail | +44 (0) 1255 440291

General | +44 (0) 1255 446838

Sales Support | +44 (0) 1255 423601 (Option 5)

Transport | +44 (0) 1255 462567

A solution designed primarily for new platforms and platform extensions. This innovative solution combines the strength of a steel foundation with the durability of a Glass Reinforced Polymer (GRP) Dura Platform surface, providing a faster, safer, and more cost-effective alternative to traditional methods.

The Dura Composites solution for Network Rail standard NR/L3/CIV/030 compliant station platform construction combines the strength of a steel foundation with a Glass Reinforced Polymer (GRP) Dura Platform surface providing an optimal solution that’s quicker, safer and more cost-effective than other traditional methods.

Using steel foundations gives the hybrid solution the strength it needs, using fewer struts. A reduction in support struts means install time is faster and fewer possessions of the station are needed to install which can result in savings from possessions of up to 42%!

In 2020 the Dura Platform rapid-deployment solution won the coveted Queen’s Award for Enterprise Innovation in recognition of its commercial success and unique patented features which promote rapid deployment and enhanced passenger safety. As well as recognising the saving in labour costs and reducing installation times for rail contractors who can manoeuvre Dura’s modular platform sections easily without the need for expensive lifting equipment and additional labour that traditional concrete platforms require.

Easily manages panel ‘creep’ and concave or convex curvature, can be cranked to an instant 1:40 fall for drainage management, enables seamless transitions from old to new platforms, and manages curves and falls.

This system provides easy access for underground services, integrates cable management, and caters for subsidence or ballast adjustment or new rolling stock.

The largest on the market, this system reduces up to 60% of footings while being up to 87.5% lighter, supporting weights of up to 2500kgs. This innovation not only saves on groundwork but also significantly reduces labor costs.

Dura Platform is a composite alternative to concrete and other solutions that are costly and can require long possessions. Made from Glass Reinforced Polymer (GRP) which complies with Network Rail specifications, Dura Platform can cut platform installation time by up to 65% and is capable of being man-handled, eliminating the need for costly RRVs or heavy lifting equipment. Its hidden fixing system minimises trip hazards, and the platform is also crankable to create an instant 1:40 fall to manage drainage.

Find out how our market-leading composite products and applications are reshaping the industry.

Explore our solutions and services to help you build resilient, greener and safer infrastructure.

Flyers

Train washing is an essential part of the daily routine for train operating companies. New…

Download

Brochures

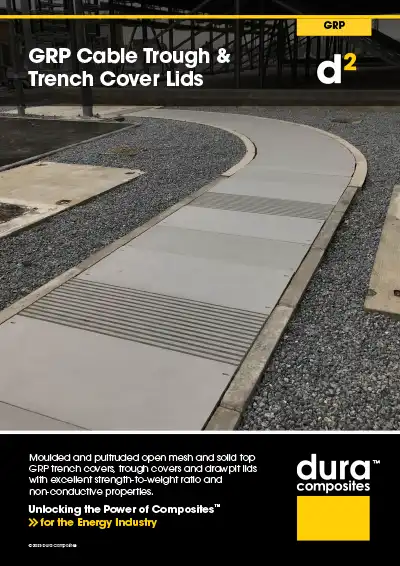

Moulded and pultruded open mesh and solid top GRP trench covers, trough covers and drawpit…

Download

Brochures

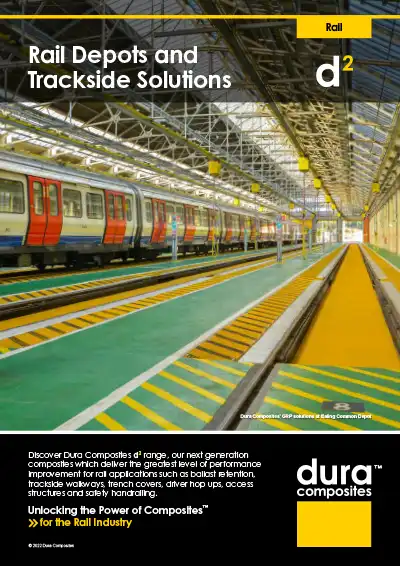

Discover Dura Composites d² range, our next generation composites which deliver the greatest level of…

Download

Brochures

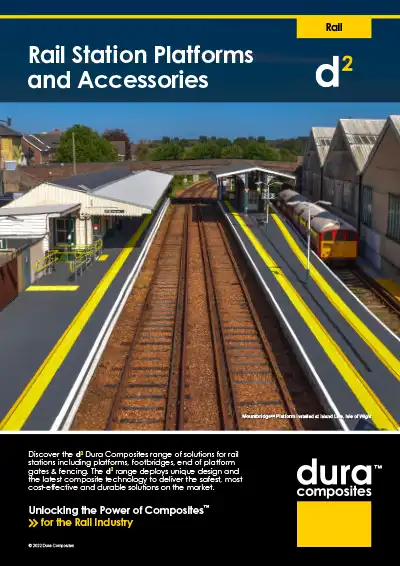

Discover the d² Dura Composites range of solutions for rail stations including platforms, footbridges, end…

DownloadWe’re helping to answer the major challenges facing Britain’s railway network such as capacity, reliability and efficiency. Talk to our experienced team about how you can tap into our specialist knowledge and engineering capability for your project.