Brochures

GRP Cable Trough & Trench Cover Lids

Moulded and pultruded open mesh and solid top GRP trench covers, trough covers and drawpit…

Download

General Sales | +44 (0) 1255 446838

Sales Support | +44 (0) 1255 423601 (Option 5)

Transport | +44 (0) 1255 462567

Rail | +44 (0) 1255 440291

Industral & Commercial | +44 (0) 1255 440290

High-Rise | +44 (0) 1255 446830

Decking & Cladding | +44 (0) 1255 440298

Marine | +44 (0) 1255 440297

We have a wealth of experience in the manufacture and supply of Trench and Access covers – both for new constructions and refurbishment applications. Let us help you Unlock the Power of Composites with a low maintenance, durable and simple to install composite Glass Reinforced Polymer (GRP) alternative to heavy & cumbersome steel or concrete covers.

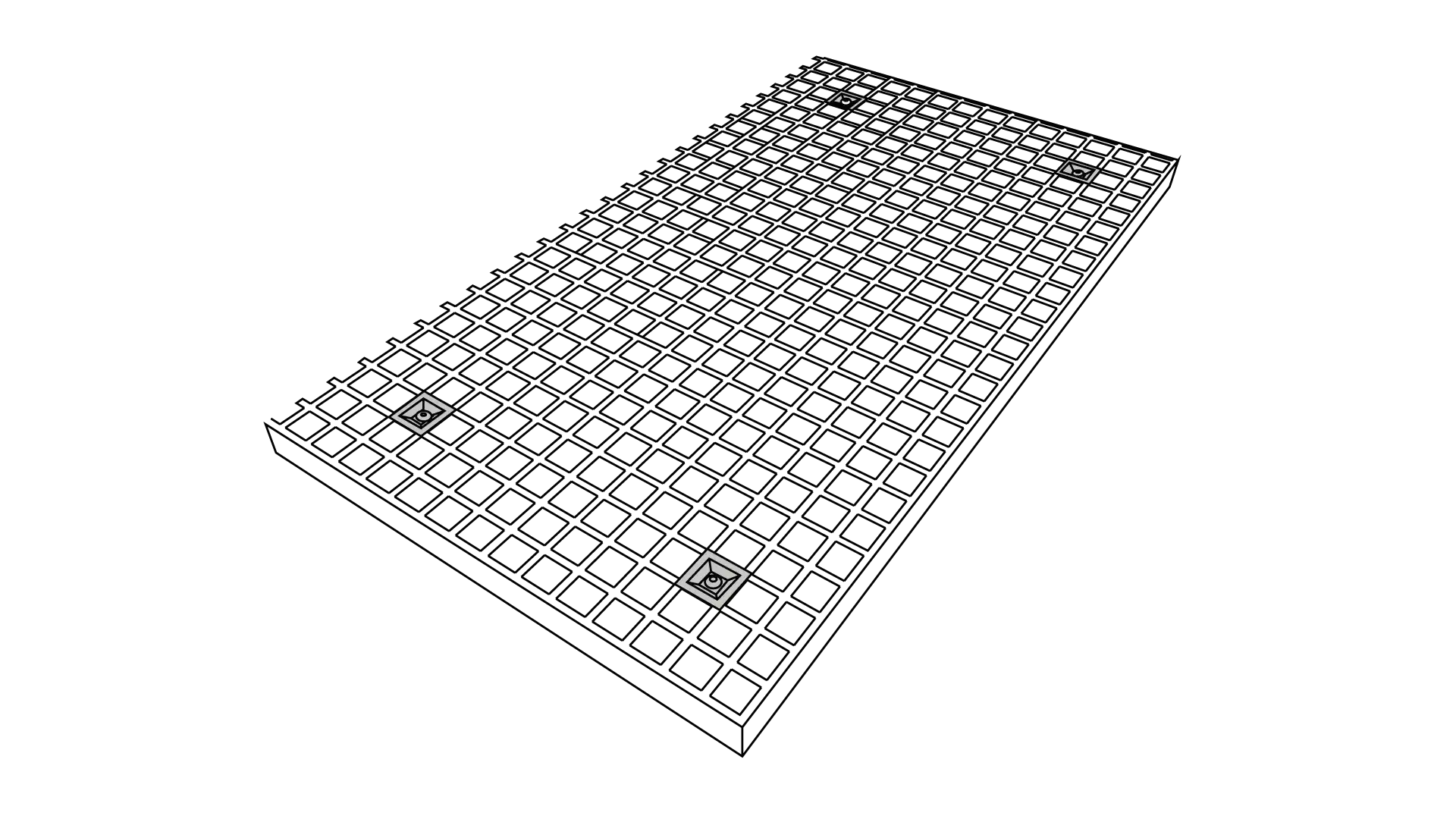

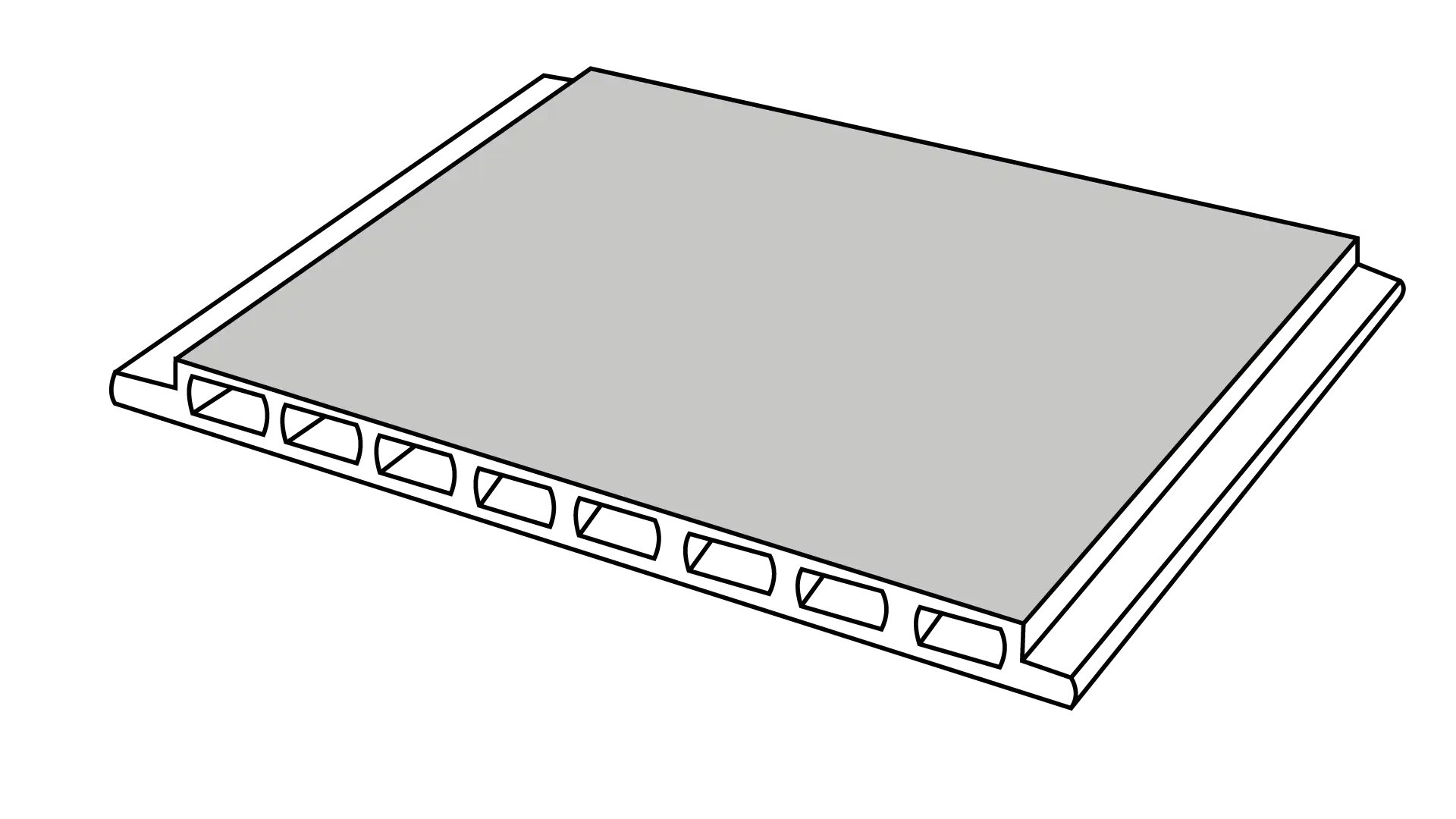

Our trench and trough covers are designed for maximum versatility and work with both precast flat top concrete troughs as well as with precast concrete troughs with a factory formed recess which enable a flush fitting with the floor surface. From open mesh to solid top lids (or a combination of both), Dura Composites has an unrivalled selection of pedestrian and vehicle rated covers to meet your specific project needs.

With an innovative design that can include either manual lifting eyes or mechanical lifting arms, our trench cover lids can meet the needs for straight sections, curved sections, right angles and Ts and have an excellent strength to weight ratio. The lightweight nature of the covers mean routine inspections and repairs can be made easily, by simply removing the appropriate covers.

Our trench cover products have additional scope for use within overlay crossing points and cable pits. Our experienced team can advise on a range of standard and bespoke scenarios and can attend site on request for pre-start project consultations. We also offer 3D laser scanning and drone surveys for areas which are difficult to inspect or which have access restrictions.

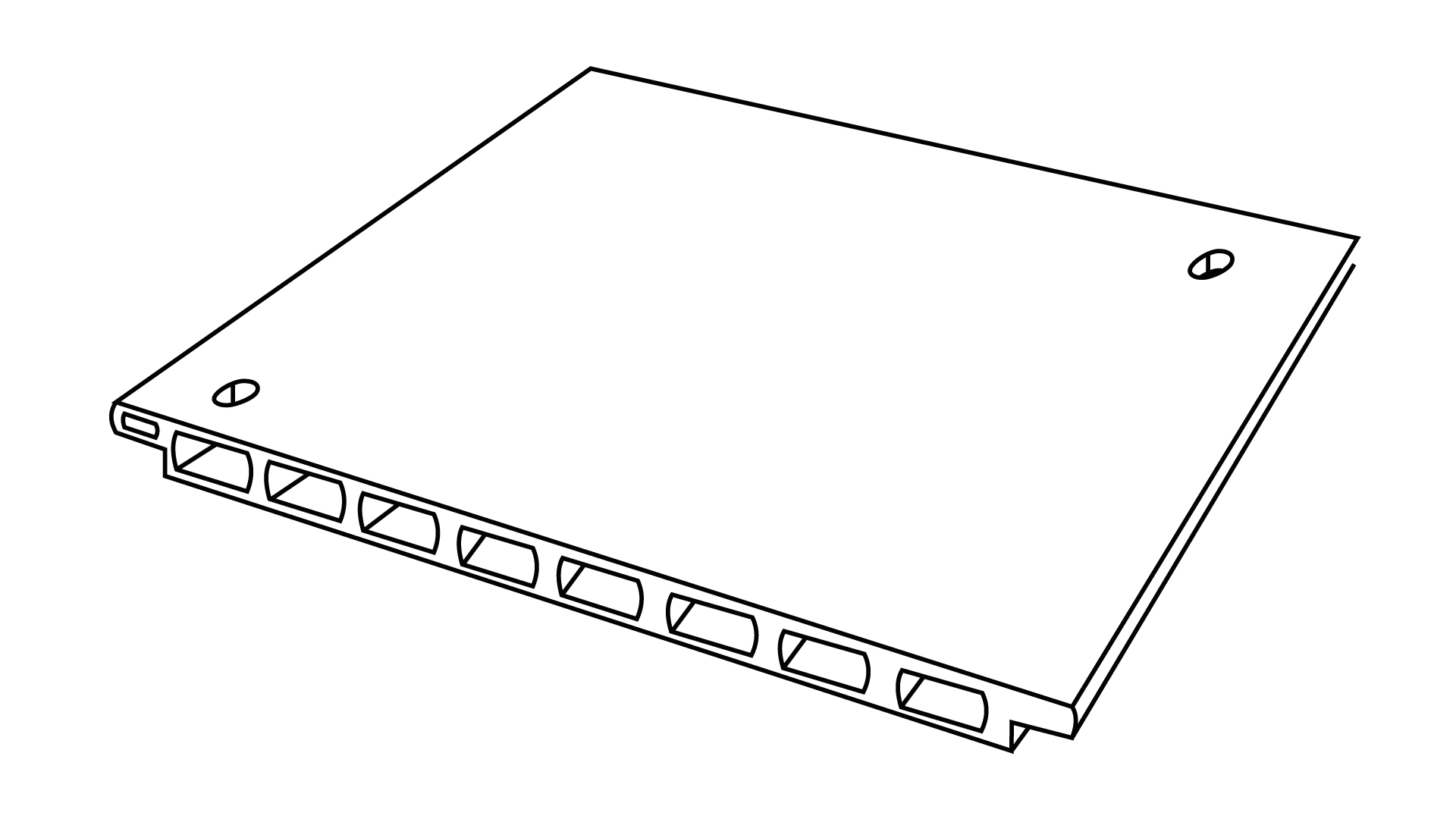

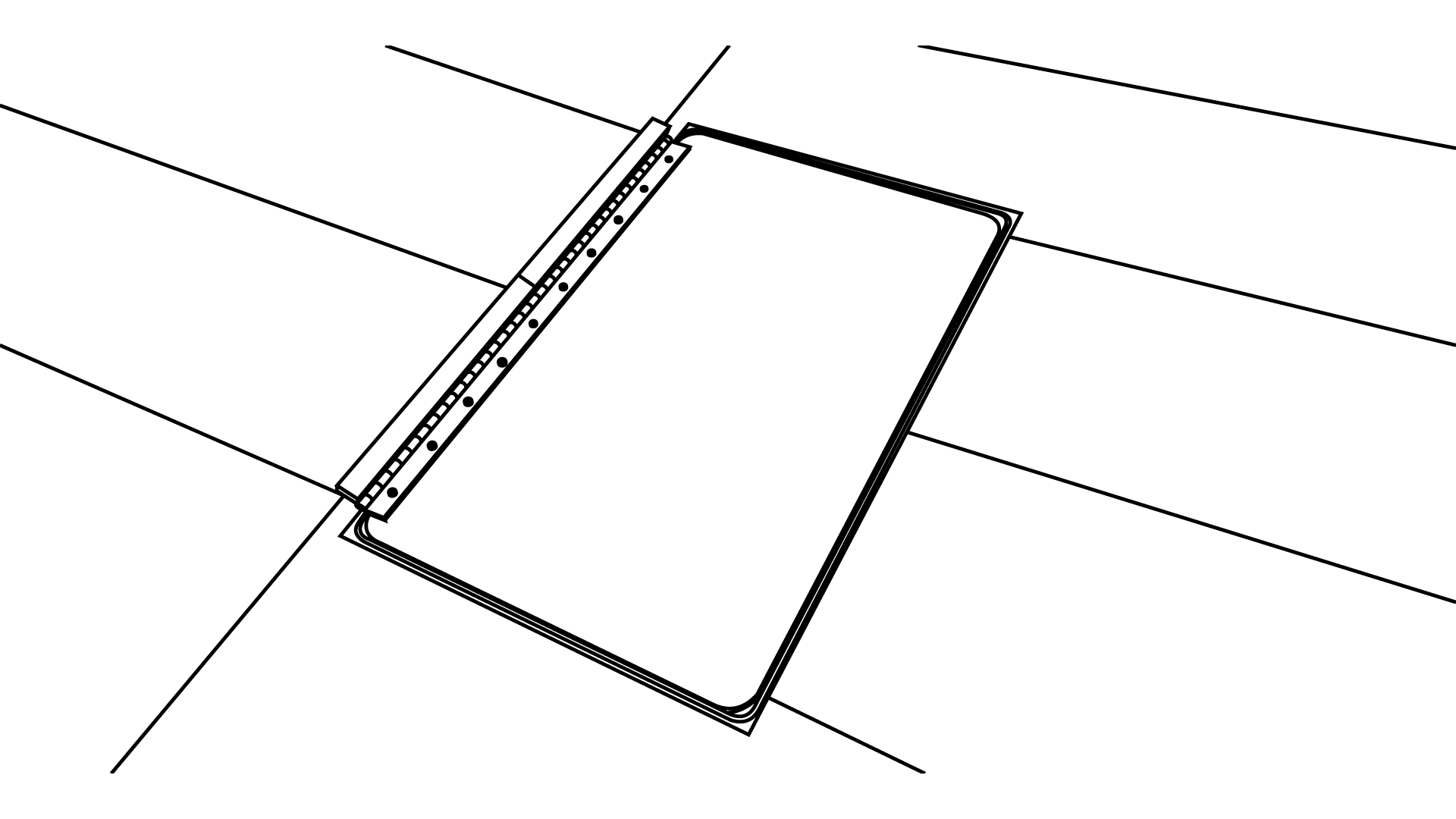

3D Model: 1250mm Trough with Dura Slab 100mm Lid

We have teamed up with Ibstock to help customers access the best in pre-cast concrete troughs and GRP composite trench covers from a single supply chain source partner

Our 50mm Rect HD & 53mm Rect HD products are the most efficient, lightest weight BS EN 124 trench covers on the market at the common 600mm span

d² Dura Grating and Dura Slab boast an industry-leading Class B fire rating per BS EN 13501-1, ensuring suitability for trench cover projects prioritising fire safety

Our partnership with Ibstock helps customers access the best in pre-cast concrete troughs and GRP composite trench covers from a single supply chain source partner. We provide UK Energy sector customers with readily available stock of concrete troughs and GRP lids alongside high levels of local technical engineering support.

We have seen a marked increase in customers requiring a combined concrete trough and GRP lid system and as a recognised leader and innovator in the market, Ibstock has enhanced it’s offering of pre-cast reinforced concrete troughs to include solutions specifically designed for the Power and Energy infrastructure sector. Ibstock troughs and Dura Composites lids are available for every trench cover project scenario.

Our range of trench covers include both Moulded Lids for pedestrian loading and Pultruded Lids for vehicular loading – offering lightweight, high-strength solutions with various load ratings and cost-effective benefits.

We offer a range of compatible accessories to complete your Trough Cover solution. Many accessories are available from stock, but some are custom manufactured to order, so please ensure you advise us of any accessory requirements at the earliest possible stage.

Supplied as standard to suit typical

manual lifting requirements. Requires

a traditional lifting key which engages

with slots in the cover.

Suits: All Solid Covers

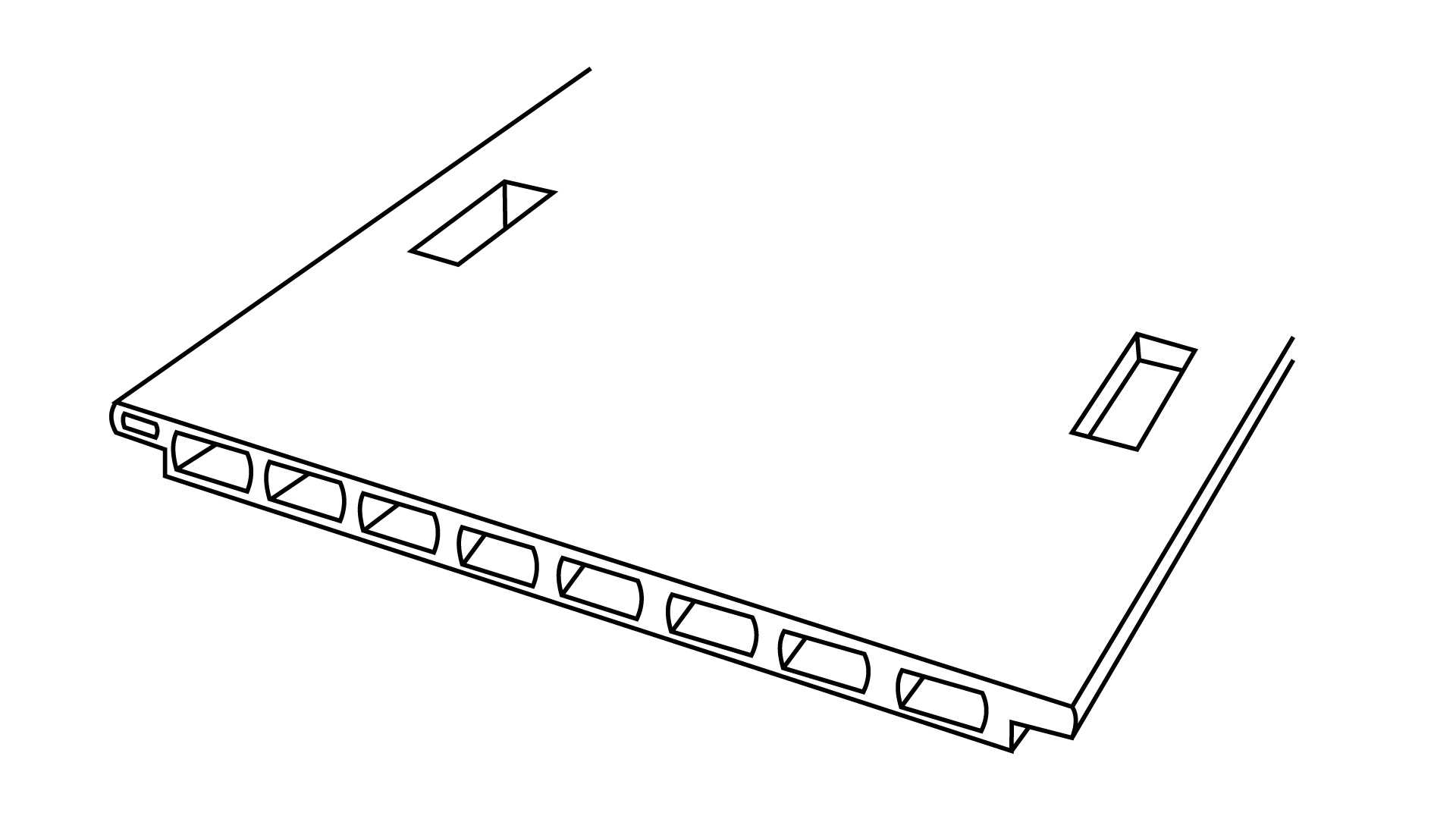

Larger lifting eye, so no key is required. Can have an affect on panel integrity due to cut out size.

Suits: All Solid Covers

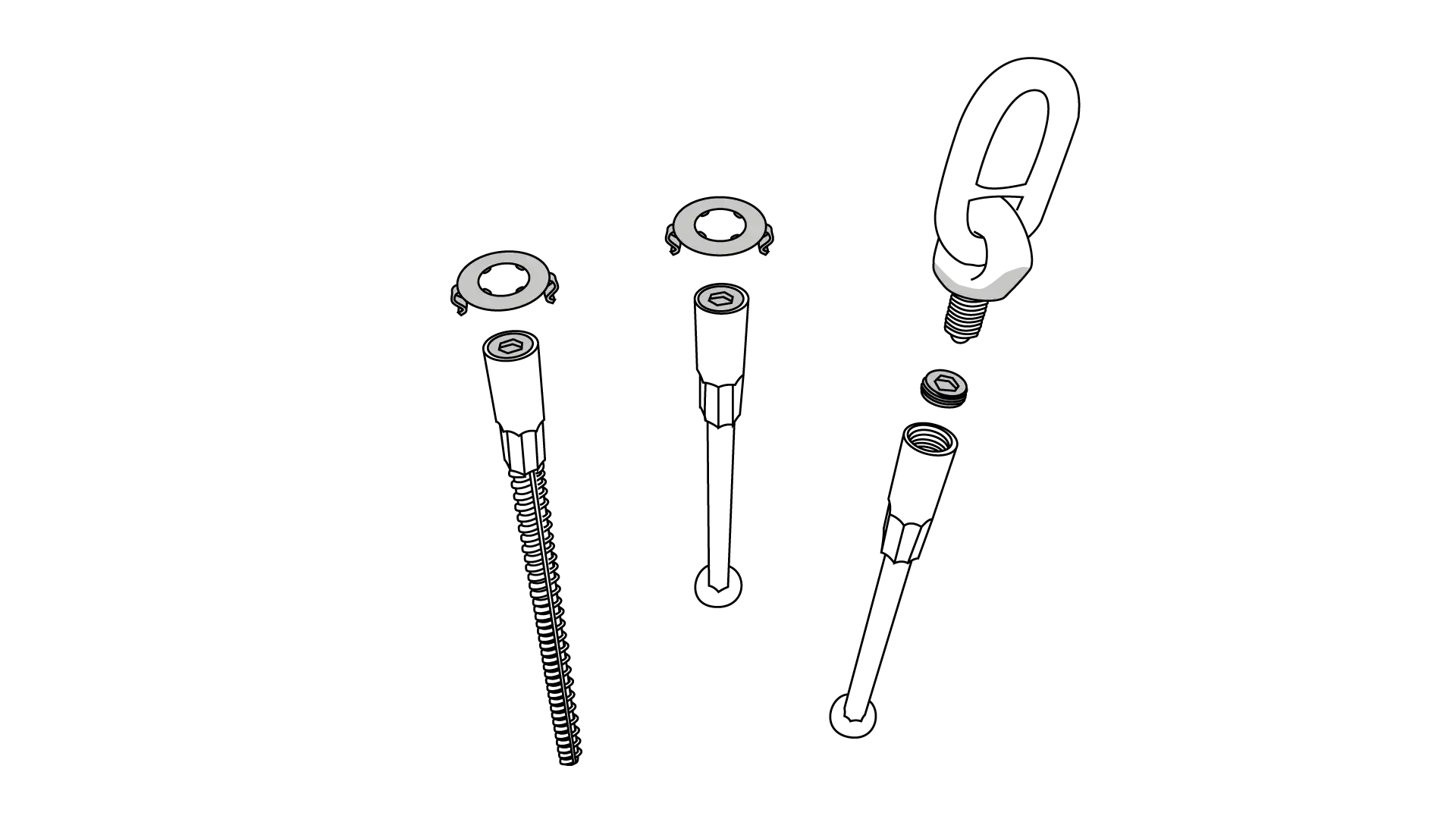

Ideal for scenarios where lifting equipment is preferred to reduce the number of personnel required to lift.

Suits: Covers too heavy for manual lift, or reduce number required to lift

Hinged covers to offer easier access to utilities without lifting keys.

Suits: All Covers

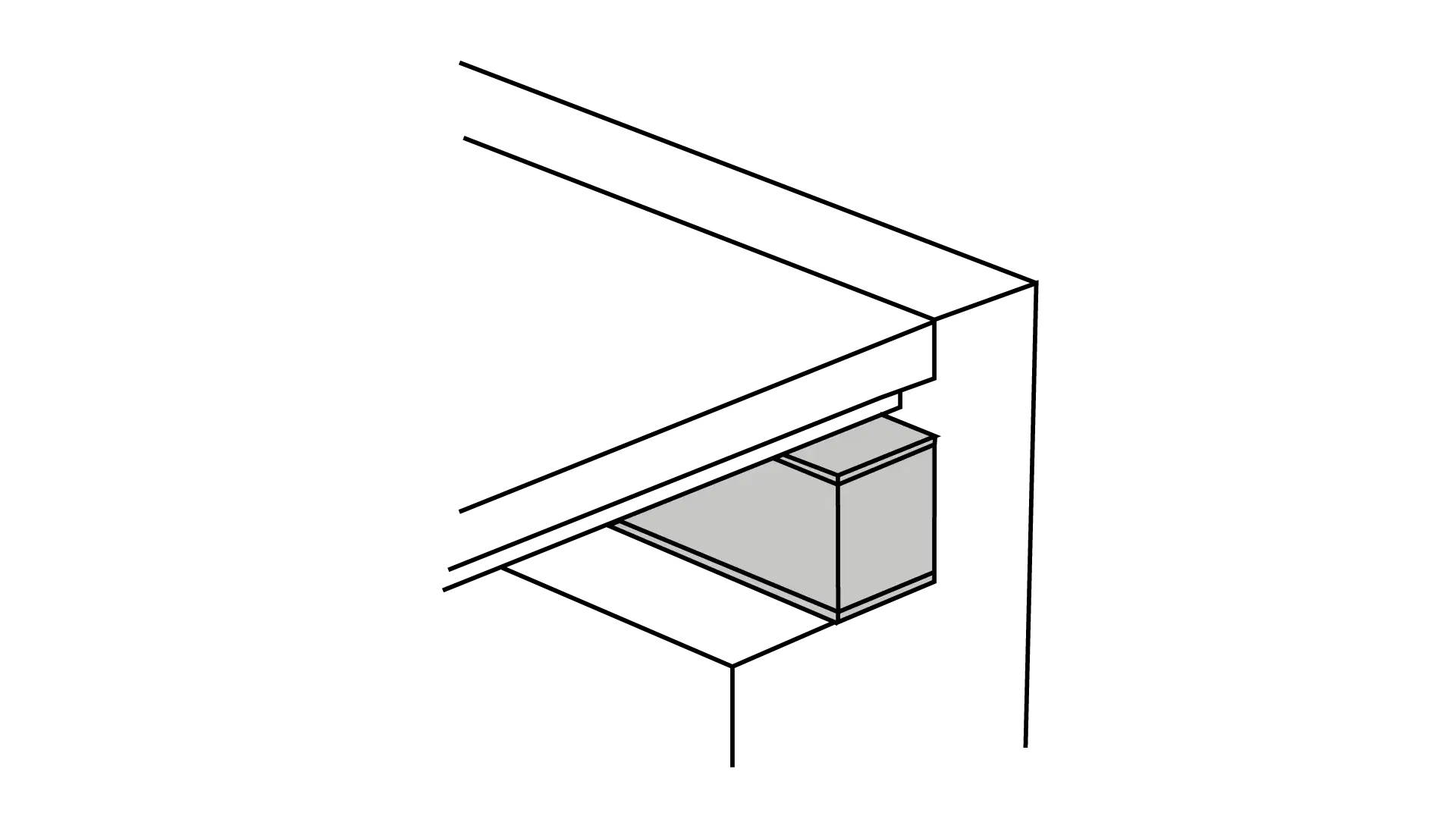

Creates rebate for cover to sit on.

Suits: All Covers

Used if there is no rebate present to retain cover position.

Suits: All Covers

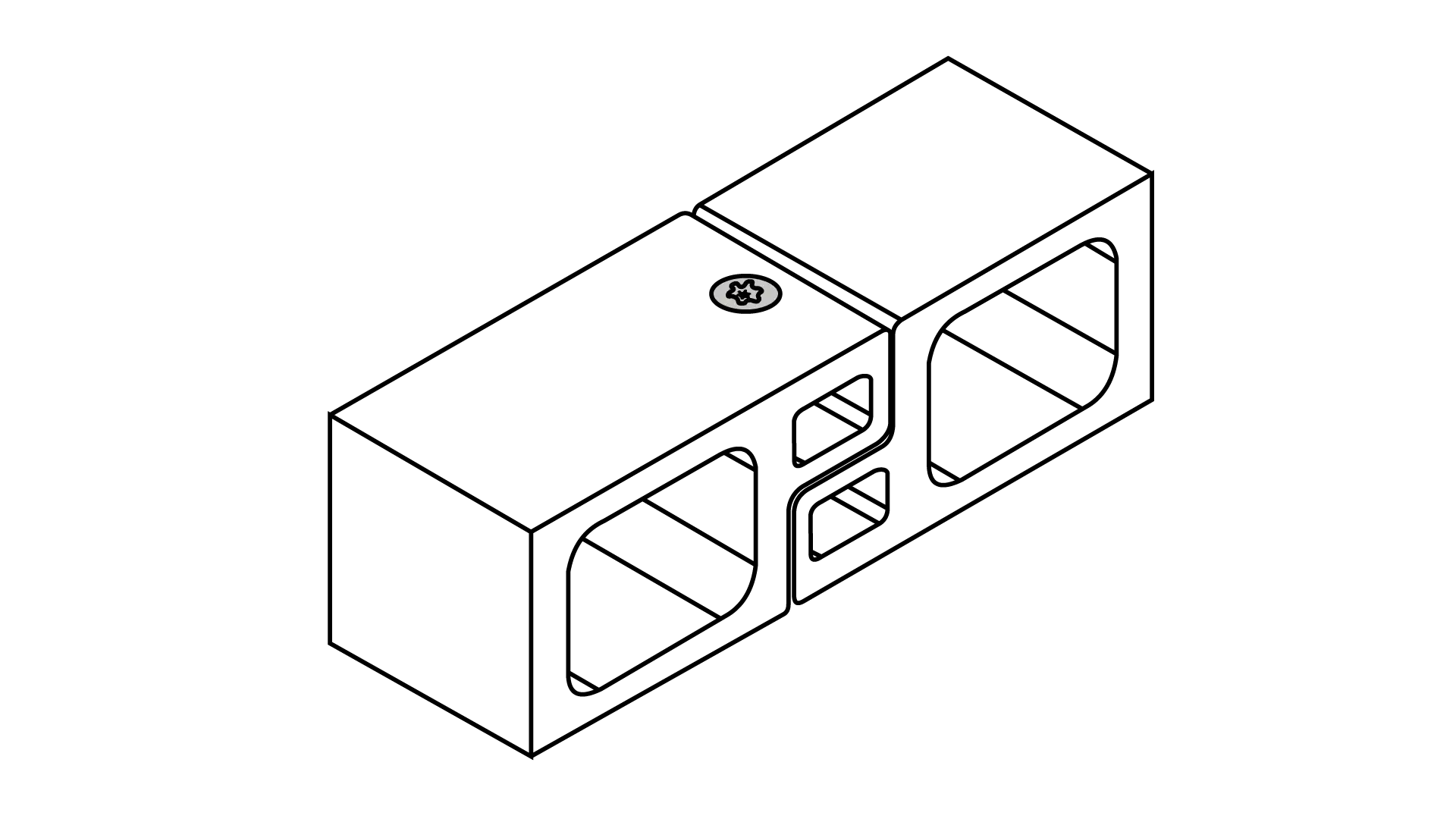

Used to fix panels together as anti-tamper device. Also removes risk of panel uplift in floods.

Suits: d² Dura Slab

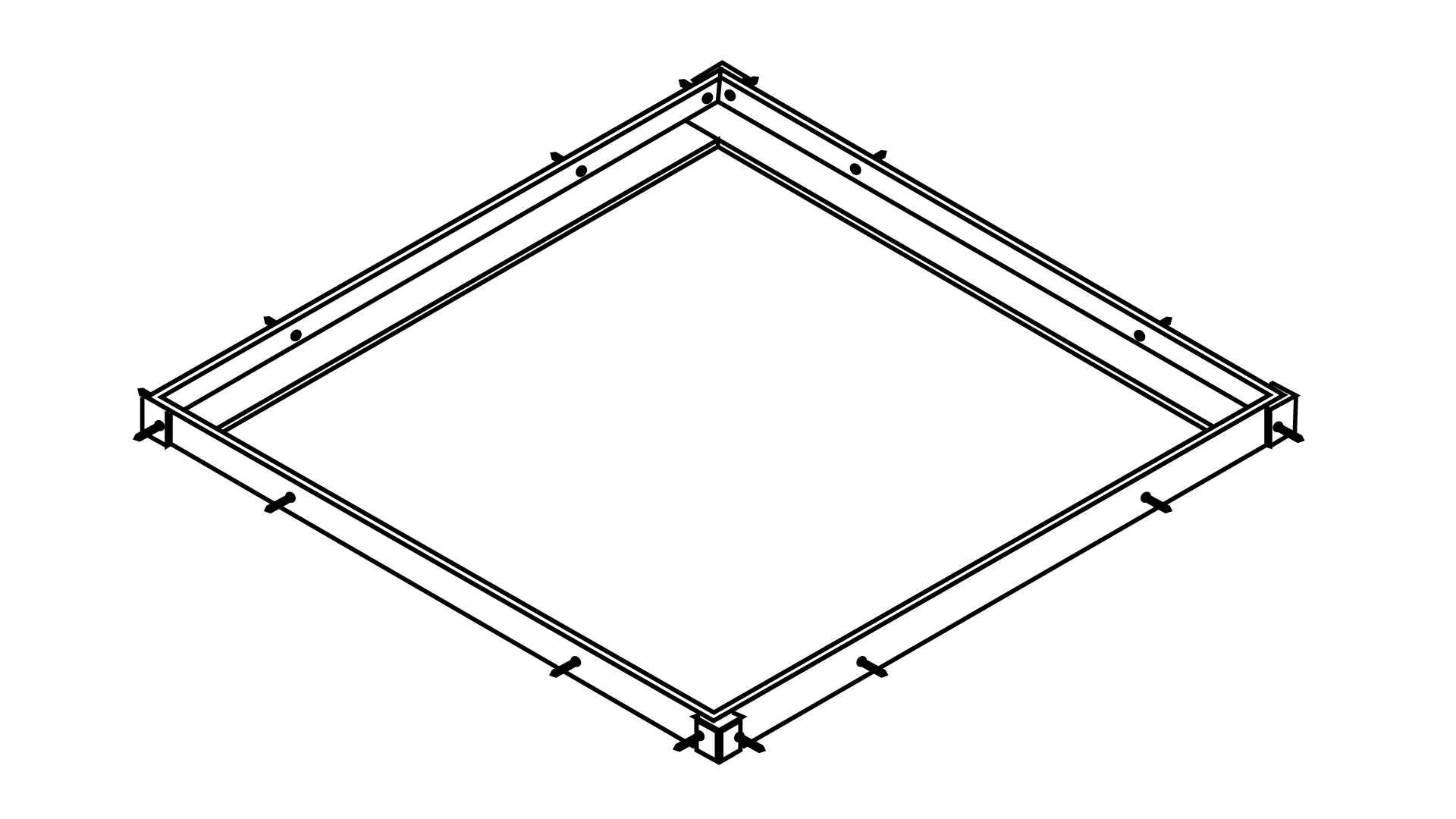

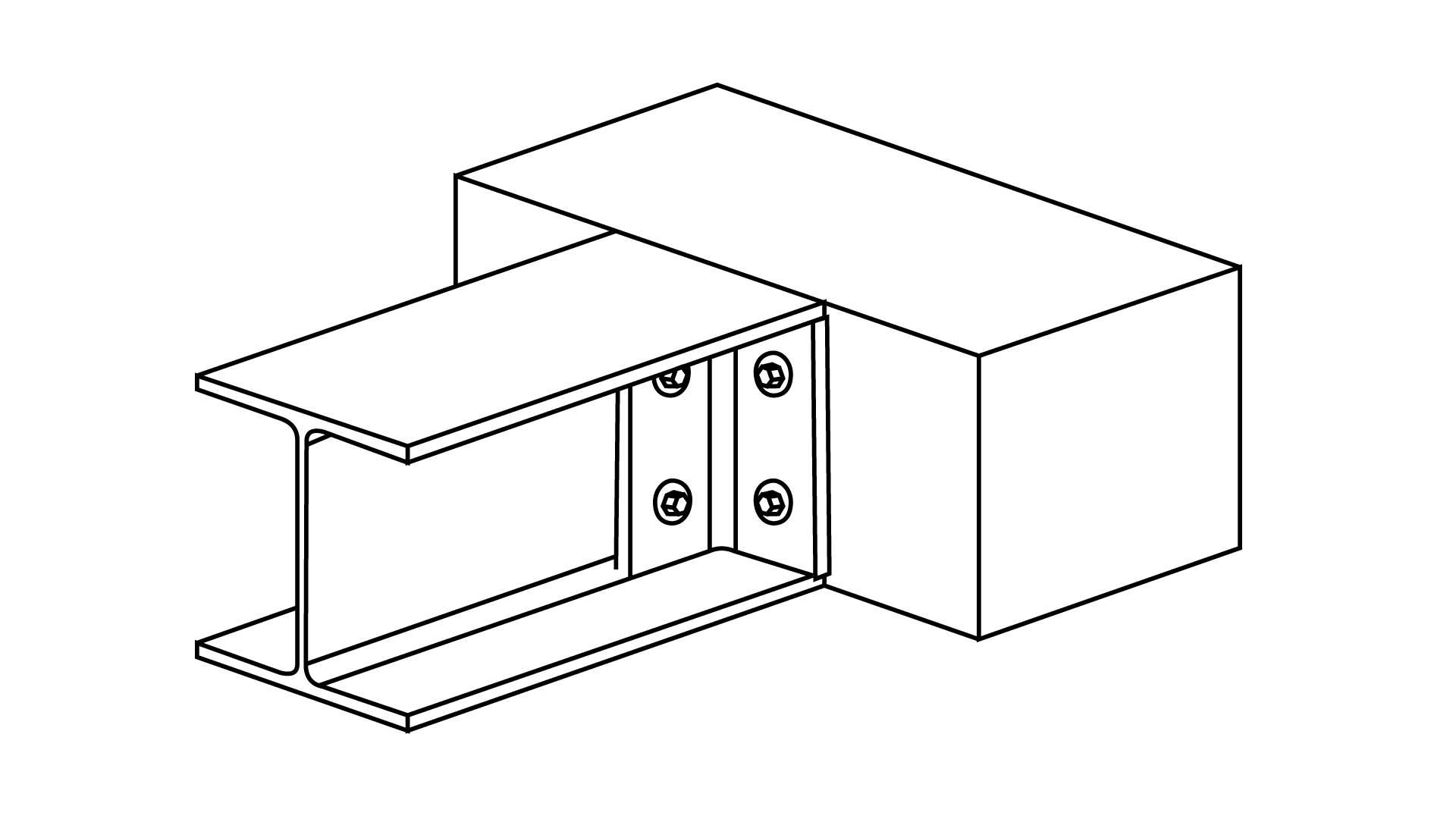

GRP and Steel substructure for trench covers to bear onto for large spans, direction changes or cut outs.

Suits: All Covers

Seal helps reduce sound when being walked on.

Suits: d² Dura Slab

Used for product identification (normally the cover load rating).

Suits: All Covers

Panels can be built up to finished level in cases of incorrect rebate height. Also suited to refurb projects.

Suits: All Covers

Our trench covers can be fitted with Radio Frequency Interference (RFI) shielding material to reduce interference from external electromagnetic signals if required.

Suits: All Covers

Find out how our market-leading composite products and applications are reshaping the industry.

Explore our solutions and services to help you build resilient, greener and safer infrastructure.

Our innovative recyclable products can help accelerate the construction of critical infrastructure. Talk to our experienced team about how you can tap into our specialist knowledge and engineering capability for your project.