Brochures

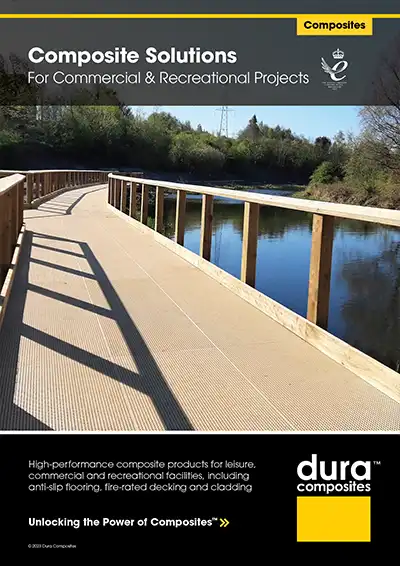

Composite Solutions for Commercial & Recreational Projects

High-performance composite products for leisure, commercial and recreational facilities, including anti-slip flooring, fire-rated decking and…

Download

Industrial | +44 (0) 1255 440290

General Sales | +44 (0) 1255 446838

Sales Support | +44 (0) 1255 423601 (Option 5)

Transport | +44 (0) 1255 462567

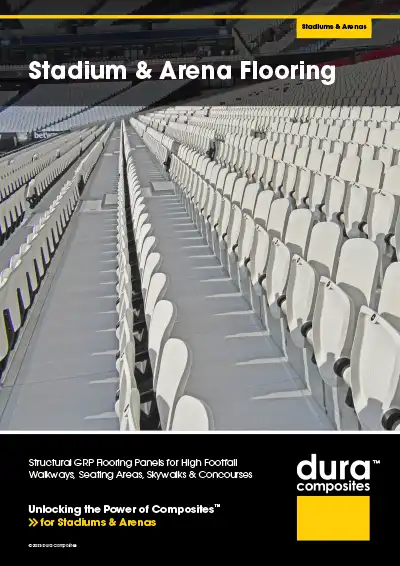

We design, manufacture, and supply lightweight, high-strength flooring panels tailored for high-traffic pedestrian zones in stadiums, arenas, and public venues. Our unique Glass Reinforced Polymer (GRP) panels excel in transitional stadium seating, concourses, walkways, and bridge decks. Successful projects include demountable, semi-permanent, and permanent seating areas, providing a durable alternative to water-prone plywood, eliminating the need for frequent replacements.

Our previous projects include flooring panels to support faster seat reconfigurations between events and which comply with the required standards for weight, loading and safety. Our most popular solution for seating areas is our 40mm GRP Dura Slab which is lightweight for easy handling during installation but has a high load bearing strength. Movement to and from seats presents an area of significant risk in stadium environments, however Dura’s GRP flooring has a robust anti-slip surface that returns an ultra-low slip potential test result in all directions, in both wet and dry conditions.

For concourse areas which need to be capable of handling extremely high levels of foot traffic, our pultruded GRP panels come in a range of different thicknesses which can be cut or shaped to accept your preferred substrate and fixing method.

Our products undergo rigorous testing to meet the standards demanded by stadium enivronments. Key tests vary by product but can include:

Find out how our market-leading composite products and applications are reshaping the industry.

Explore our solutions and services to help you build resilient, greener and safer infrastructure.

Brochures

High-performance composite products for leisure, commercial and recreational facilities, including anti-slip flooring, fire-rated decking and…

Download

Brochures

Structural GRP Flooring Panels for High Footfall Walkways, Seating Areas, Skywalks & Concourses.

Download

Brochures

High performance composite flooring and walkway solutions including trench covers, A2 fire rated decking, access…

DownloadOur innovative recyclable products can help accelerate the construction of critical infrastructure. Talk to our experienced team about how you can tap into our specialist knowledge and engineering capability for your project.