Brochures

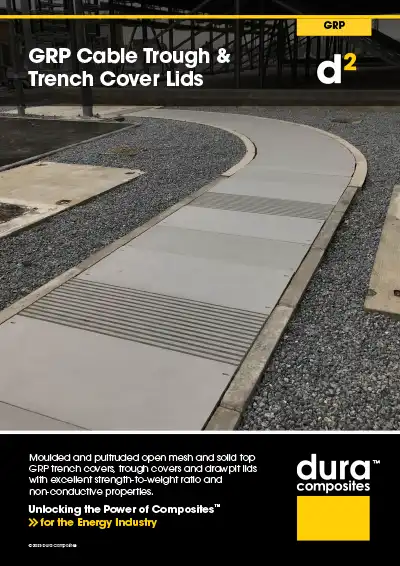

GRP Cable Trough & Trench Cover Lids

Moulded and pultruded open mesh and solid top GRP trench covers, trough covers and drawpit…

Download

General Sales | +44 (0) 1255 446838

Sales Support | +44 (0) 1255 423601 (Option 5)

Transport | +44 (0) 1255 462567

Rail | +44 (0) 1255 440291

Industral & Commercial | +44 (0) 1255 440290

High-Rise | +44 (0) 1255 446830

Decking & Cladding | +44 (0) 1255 440298

Marine | +44 (0) 1255 440297

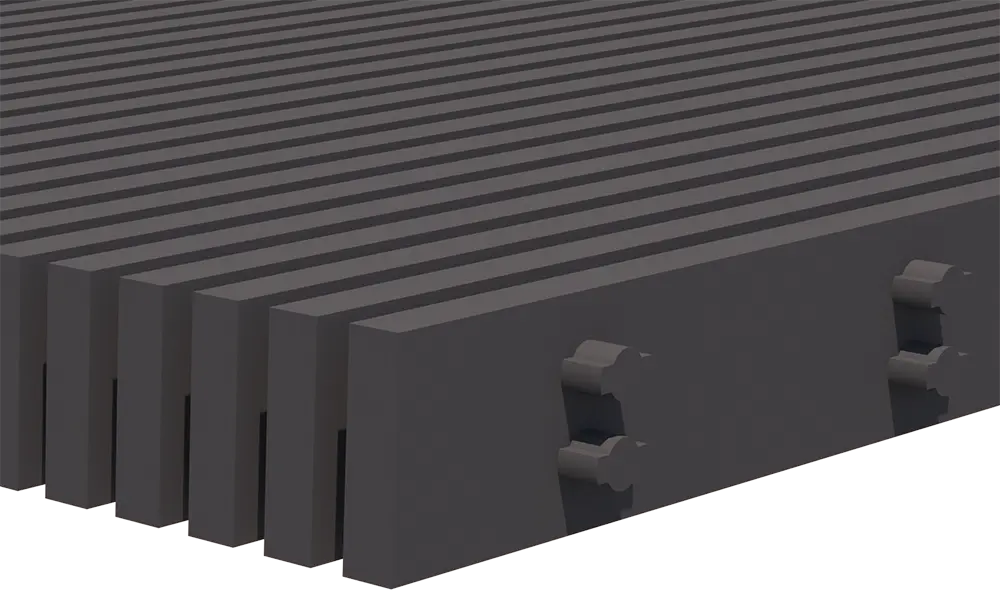

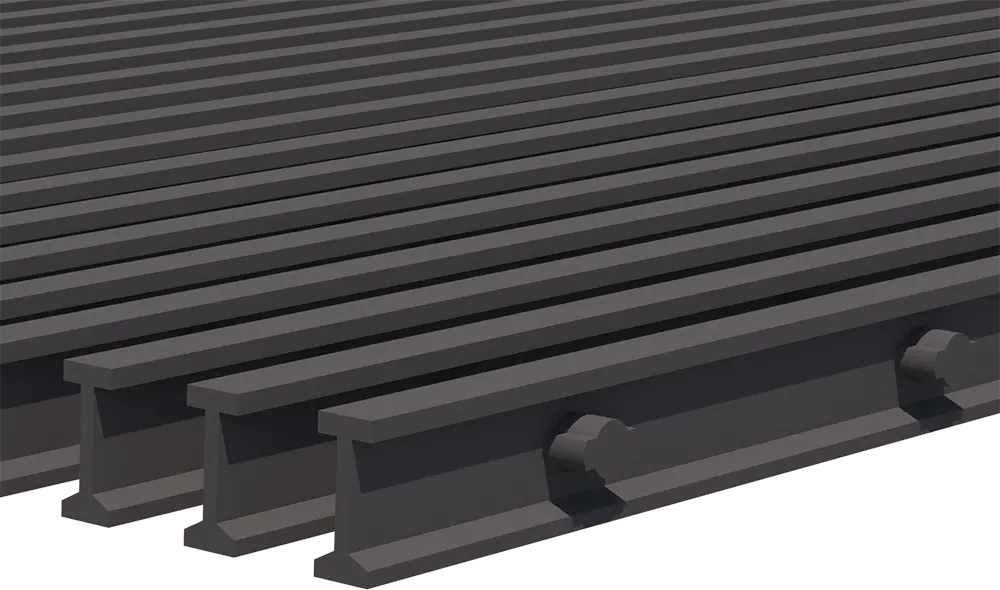

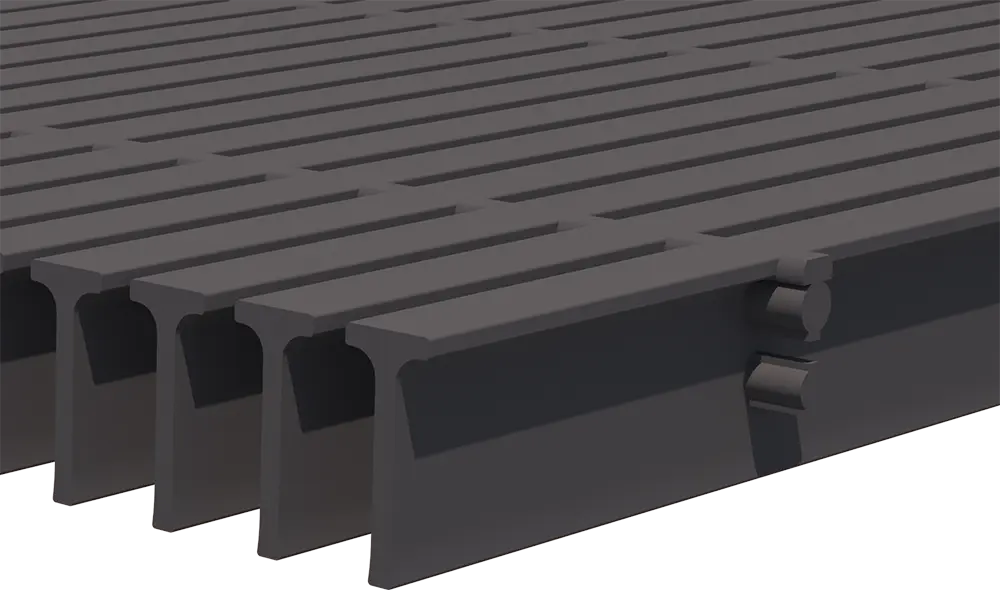

Our pultruded GRP Grating is an alternative to our moulded grating panels and has various structural shapes, ideal for areas with regular impact that require an extended drainage solution and wide span. All the variants utilise distinct bearing bar shapes and sizes, offering excellent bi-directional strength and stiffness. The selection depends on project-specific requirements, including load-bearing needs and overall aesthetics.

Provides a smooth, flat surface suitable for pedestrian areas and locations requiring enhanced drainage.

Features an I-shaped cross-section with flanges on both sides of a central web.

Exhibits a T-shaped cross-section with a central web and flanges extending beyond the web for added lateral stiffness.

Dura Composites’ pultruded open safety flooring excels in areas with regular impact, offering extended drainage and wide spans. Its durability, lightweight nature, corrosion, and chemical resistance surpass traditional materials like steel. The pultrusion process ensures a consistent, high-quality product, featuring pultruded load bars connected by tie bars.

Dura Grating in blue is a preferred choice for rail catchpit covers, aquaculture industries, and drainage walkway solutions in busy leisure centers. Pultruded components are also ideally suited as trench covers to vehicular loading requirements for infrastructure installs including power, telecoms and utility projects.

Ability to achieve wide spans for pedestrian loads.

Ideal for hazardous utility and energy environments.

Perfect for reducing risk in high-voltage areas.

| Thickness | Open Hole Size | Standard Compliance | Max Span | Length | Width | Weight | Colours |

|---|---|---|---|---|---|---|---|

| 38mm | 10mm | EN 124 Class A | 1300mm | 3660mm | 1220mm | 23kg/m² | Green, Yellow, Dark Grey, Blue |

| 38mm | 23mm | EN 124 Class A | 1600mm | 3660mm | 1220mm | 16kg/m² | Green, Yellow, Dark Grey, Blue |

| Thickness | Open Hole Size | Standard Compliance | Max Span | Length | Width | Weight | Colours |

|---|---|---|---|---|---|---|---|

| 50mm | 10mm | EN 124 Class A | Max Span | 1800mm | 3660mm | 1220mm | 24kg/m² | Green, Yellow, Dark Grey |

| 50mm | 23mm | EN 124 Class A | 1700mm | 3660mm | 1220mm | 16kg/m² | Green, Yellow, Dark Grey |

| 63mm | 10mm | EN 124 Class A | 1900mm | 3660mm | 1220mm | 28kg/m² | Green, Yellow, Dark Grey |

| 63mm | 23mm | EN 124 Class A | 1800mm | 3660mm | 1220mm | 19kg/m² | Green, Yellow, Dark Grey |

| Thickness | Open Hole Size | Standard Compliance | Max Span | Length | Width | Weight | Colours |

|---|---|---|---|---|---|---|---|

| 38mm | 10mm | EN 124 Class B | 900mm | 3660mm | 1220mm | 54kg/m² | Green, Yellow, Dark Grey |

| 38mm | 23mm | EN 124 Class B | 730mm | 3660mm | 1220mm | 34kg/m² | Green, Yellow, Dark Grey |

| 50mm | 10mm | EN 124 Class B | 1200mm | 3660mm | 1220mm | 71kg/m² | Green, Yellow, Dark Grey |

| 50mm | 23mm | EN 124 Class B | 1000mm | 3660mm | 1220mm | 44kg/m² | Green, Yellow, Dark Grey |

| 63mm | 10mm | EN 124 Class C | 600mm | 3660mm | 1220mm | 80kg/m² | Green, Yellow, Dark Grey |

| 63mm | 23mm | EN 124 Class C | 600mm | 3660mm | 1220mm | 58kg/m² | Green, Yellow, Dark Grey |

| 100mm | 10mm | EN 124 Class D | 700mm | 3660mm | 1220mm | 119kg/m² | Green, Yellow, Dark Grey |

| 100mm | 23mm | EN 124 Class C | 700mm | 3660mm | 1220mm | 80kg/m² | Green, Yellow, Dark Grey |

Need further Technical Information, Point Load And UDL data? Click here to use our GRP Material Data Analysis Tool

Explore our solutions and services to help you build resilient, greener and safer infrastructure.

Find out how our market-leading composite products and applications are reshaping the industry.